Method and apparatus for chip-cooling

a technology of heat conducting pad and chip, which is applied in the direction of cooling/ventilation/heating modification, semiconductor device details, semiconductor/solid-state device details, etc., can solve the problems of limited chip cooling, thermal runaway, and general limited thermal conductivity of conventional paste, so as to facilitate inspection and repair of the ic device, speed up heat transfer, and facilitate the effect of cooling the ic chip faster and more efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

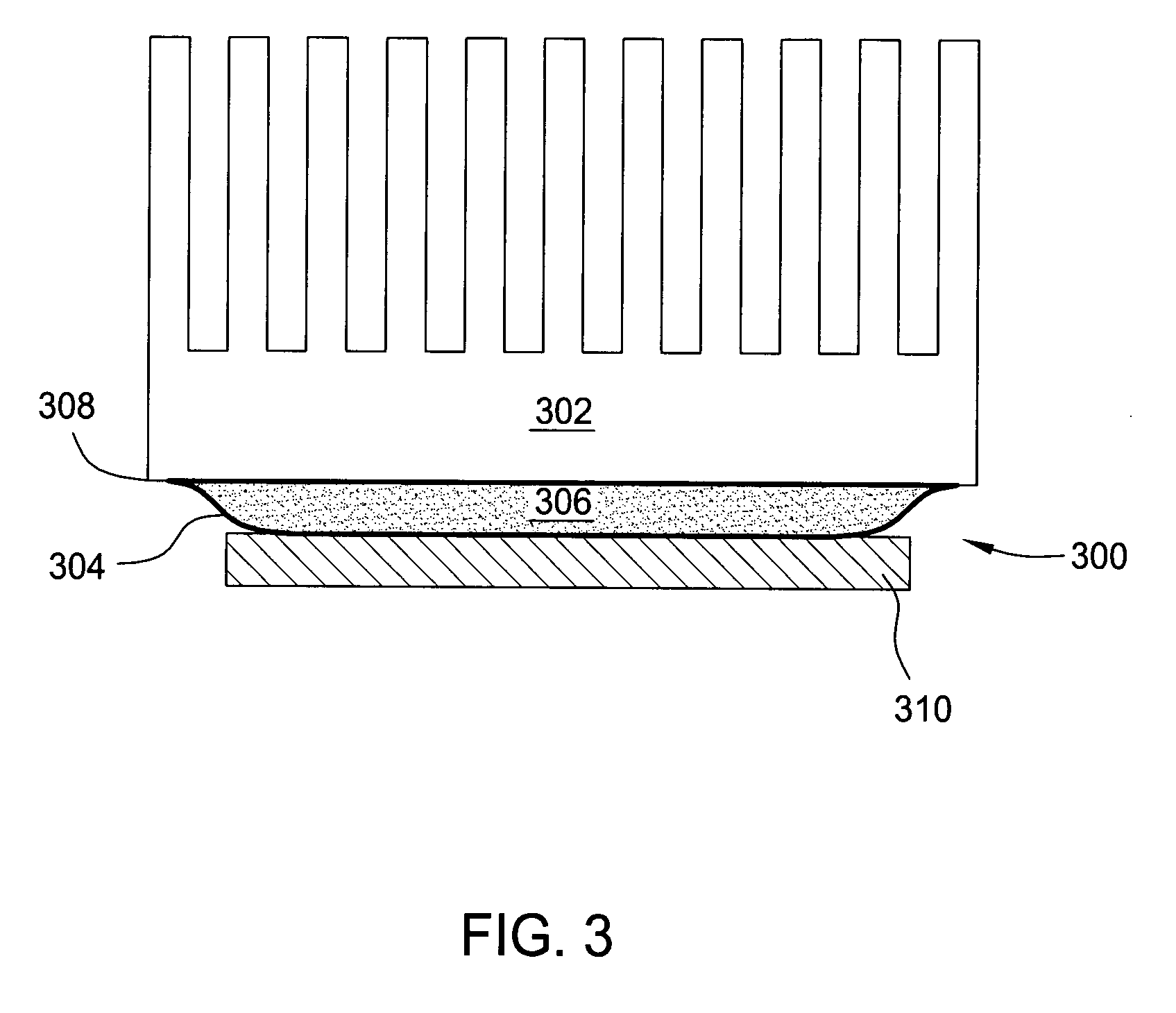

[0025]FIG. 3 is a cross sectional view of a thermal interface 300 according to the present invention. The thermal interface 300 is substantially similar to the thermal interface 100 discussed with respect to FIGS. 1 and 2; however, the thermal interface 300 is integrated directly into the heat sink 302. The thermal interface 300 therefore comprises only one flexible sheet 304, and the liquid metal 306 is retained between the sheet 304 and the first surface 308 of the heat sink 302. Integration of the thermal interface 300 with the heat sink 302 simplifies the design mechanically, and also significantly improves thermal conductivity by eliminating a layer of sheet material from the thermal interface 300 (i.e., the sheet of the enclosure 108 that is adjacent to the heat sink 202 in FIG. 2) between the chip 310 and the heat sink 302. Thus a semi-flexible enclosure is defined between the sheet 304 and the first surface 308 of the heat sink 302.

third embodiment

[0026]FIG. 4 is a cross sectional view of a thermal interface 400 according to the present invention. In the embodiment illustrated, the liquid metal 402 is retained by the first surfaces 404, 406 of the chip 408 and the heat sink 410, and by a resilient gasket 412 that seals the perimeter of the chip / heat sink interface. The elimination of sheets such as those described with reference to FIGS. 2 and 3 to retain the liquid metal 402 allows the liquid metal 402 to directly contact both the chip 408 and the heat sink 410, providing enhanced thermal contact between the two. Those skilled in the art will appreciate the gasket 412 may take any form that allows the gasket 412 to trap the liquid metal 402 between the chip 408 and the heat sink 410, including, but not limited to, an “O” ring seal positioned between the chip 408 and the heat sink 410.

fourth embodiment

[0027]FIG. 5 is a cross sectional view of a thermal interface 500 according to the present invention. The thermal interface 500 is substantially similar to the thermal interface 100 described with respect to FIGS. 1 and 2; however, a liner 502 lines the interior surface of the enclosure 504. The liner 502 comprises a thin layer of a flexible, thermally conductive material. The liner substantially prevents chemical reactions between the liquid metal 506 and the sheets of the enclosure 504, and also improves wetting of the liquid metal 506 to the sheets of the enclosure 504 (which increases thermal conductivity). In one embodiment, the liner 502 is formed from a chemically inert material. Suitable chemically inert materials include, but are not limited to, noble metals (e.g., platinum, tantalum and gold, among others). In further embodiments, the liner 502 is formed from a material that adheres well to the interior surface of the enclosure 504 and remains stable when subjected to vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com