Germanium and germanium alloy nanoparticle and method for producing the same

a germanium alloy and nanoparticle technology, applied in the field of nanomaterials, can solve the problems of limited detection efficiency and wavelength range of bulk silicon-based photodetectors, and conventional optical detectors made on compound semiconductor substrates are bonded with bulk silicon dies for a multi-chip solution that is relatively expensive,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

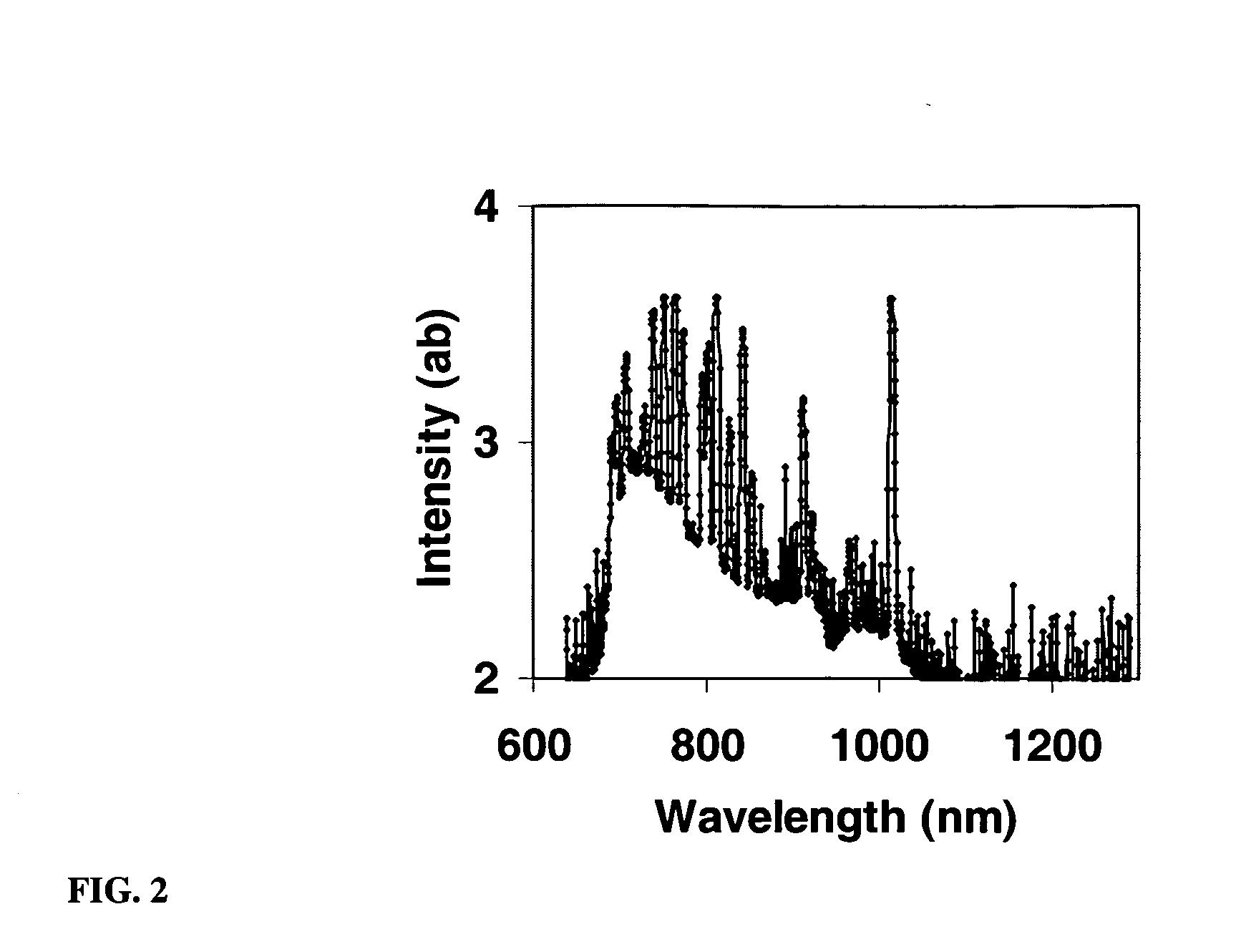

[0012] The invention concerns germanium and germanium alloy nanoparticles and methods for making the same. Infrared emissions from nanaparticles command a special interest in myriad applications. Highly-efficient nanomaterial-based photodetectors or phototransistors in the infrared can form the basis for chip-to-chip and board-to-board optical interconnects. In relation to bulk silicon, bulk germanium reduces the indirect band gap (0.66 vs. 1.1 eV), and the direct band gaps (0.9 vs. 3.2 eV), and one use of germanium nanoparticles of the invention is to extend the photosensitive response into the infrared.

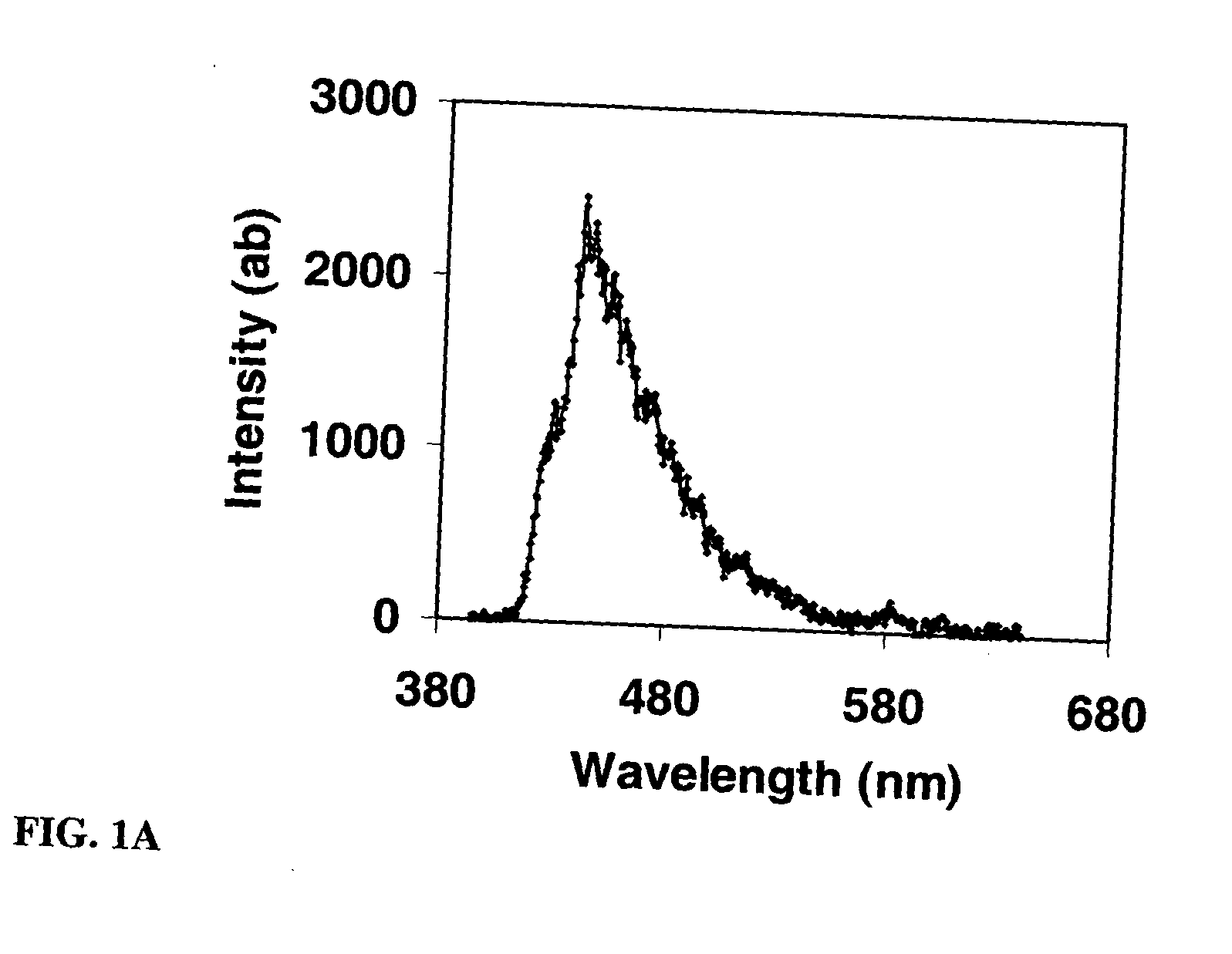

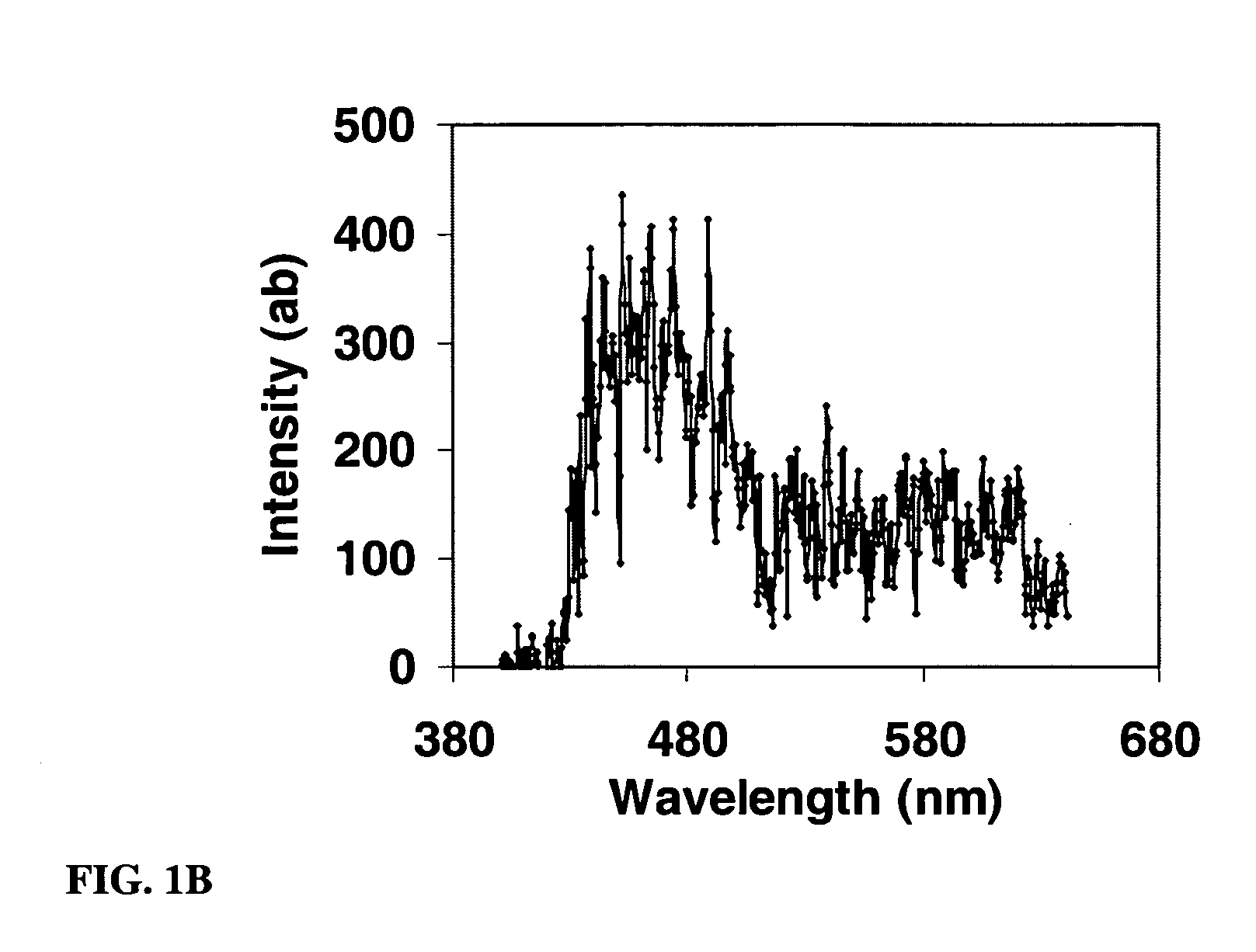

[0013] In the invention, we employ electrochemical etching processes of crystalline germanium or a germanium alloy in a chemical etchant solution, e.g., HF / H2O2 / H2O to produce, well-segregated chromatic clusters of nanoparticle material, which under 365 nm UV excitation, exhibit ultrabright blue, green, and yellow / orange photoluminescence, as well as very efficient infrared radiati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com