Oxygen scavenger for low moisture environment and methods of using the same

a technology of oxygen scavenger and low moisture environment, which is applied in the field of oxygenabsorbents, can solve the problems of oxygen being typically detrimental to food and pharmaceuticals, many products can have longer shelf life if oxygen is diminished, and limited in application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

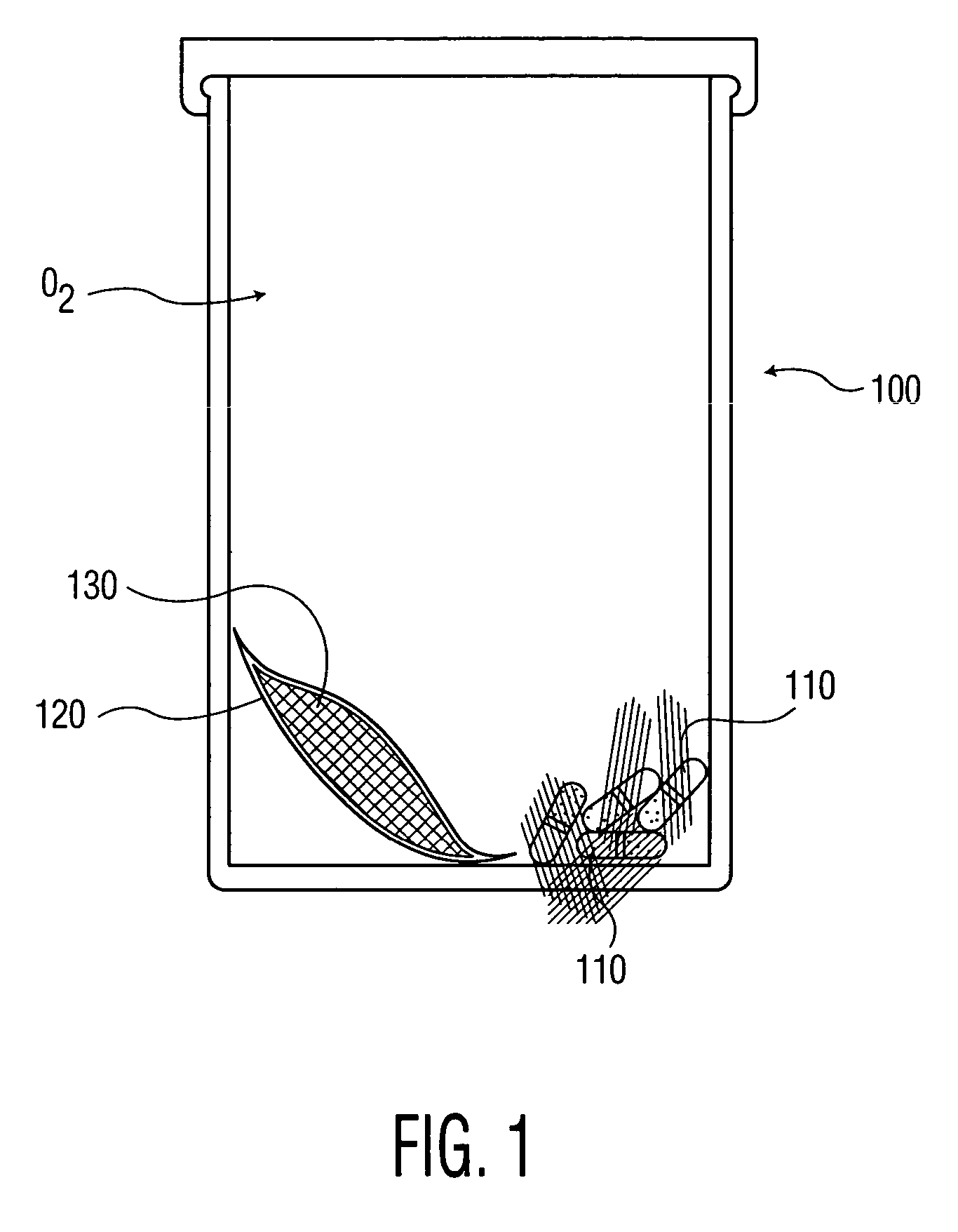

Image

Examples

example 1

[0032] An oxygen-absorbing blend was prepared by combining 20 grams (g) sodium chloride (NaCl), 10 g ascorbic acid (C6H8O6), and 10 g sodium ascorbate (Na—C6H7O6) with 60 g of water. This mixture was combined 45 / 55 with silica gel. The blend was found to have an ERH of 59%. Seventy-five one hundredths of a gram (0.75 g) of this blend was mixed with 0.75 g of 200 mesh electrolytic iron and sealed within a semipermeable sachet.

[0033] The sachet was placed within a high barrier test container with a measured amount of air and was found to absorb over 200 cc of oxygen in 60 days in a dry atmosphere. During this time the ERH within the test container did not exceed 51%.

example 2

[0034] An oxygen absorbing blend was prepared by combining 10 g sodium chloride and 20 g calcium chloride with 70 g of water. This mixture was combined 45 / 55 with silica gel. The blend was found to have an ERH of 48.3%.

[0035] Two grams (2 g) of this blend was mixed with 1 g of 200 mesh electrolytic iron and sealed within a semipermeable sachet. The sachet was a laminate of water-oil-grease resistant paper and a linear low density polyethylene film. The film had a water vapor transfer rate of 0.456 g / 100 in2 / day @1100° F., 90% r.h. and an oxygen transfer rate of 61.8 cc / 100 in2 / day @ 73° F., 50% r.h.

[0036] The sachet was placed within a high barrier test container with 500 cc of air and was found to absorb over 37 cc of oxygen in 66 days in a dry atmosphere.

example 3

[0037] An oxygen absorbing blend was prepared by combining 10.4 g sodium chloride, 20.8 g calcium chloride, and 68.8 g of water. This mixture was combined 45 / 55 with silica gel.

[0038] 1.2 g of this blend was mixed with 1.2 g of 200 mesh electrolytic iron, combined with 0.1 g of a 50% dispersion of a binder (polyvinyl pyrollidone) and sealed within a semipermeable canister. The canister was constructed of a cylindrical polyethylene body and a film end material. The end material had a water vapor transfer rate of 0.008 g / 100 in2 / day and an oxygen transfer rate of 45 cc / 100 in2 / day @ 73° F., 50% r.h.

[0039] The canister was placed within a high barrier test container with a measured amount of air and was found to absorb oxygen at the rate of 0.85 cc / day. During this time the ERH within the test container did not exceed 56.9%. The same formulation ceased to absorb after 13 days in a permeable sachet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| equilibrium relative humidity | aaaaa | aaaaa |

| equilibrium relative humidity | aaaaa | aaaaa |

| RH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com