Electrical power connector

a technology of electrical connectors and power plugs, applied in the direction of coupling device connections, emergency protective circuit arrangements, coupling device details, etc., can solve the problems of inability to supply control current at zero crossing, heat and fire, and easy failure of line voltage electrical connectors, etc., to achieve the effect of not excessive hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

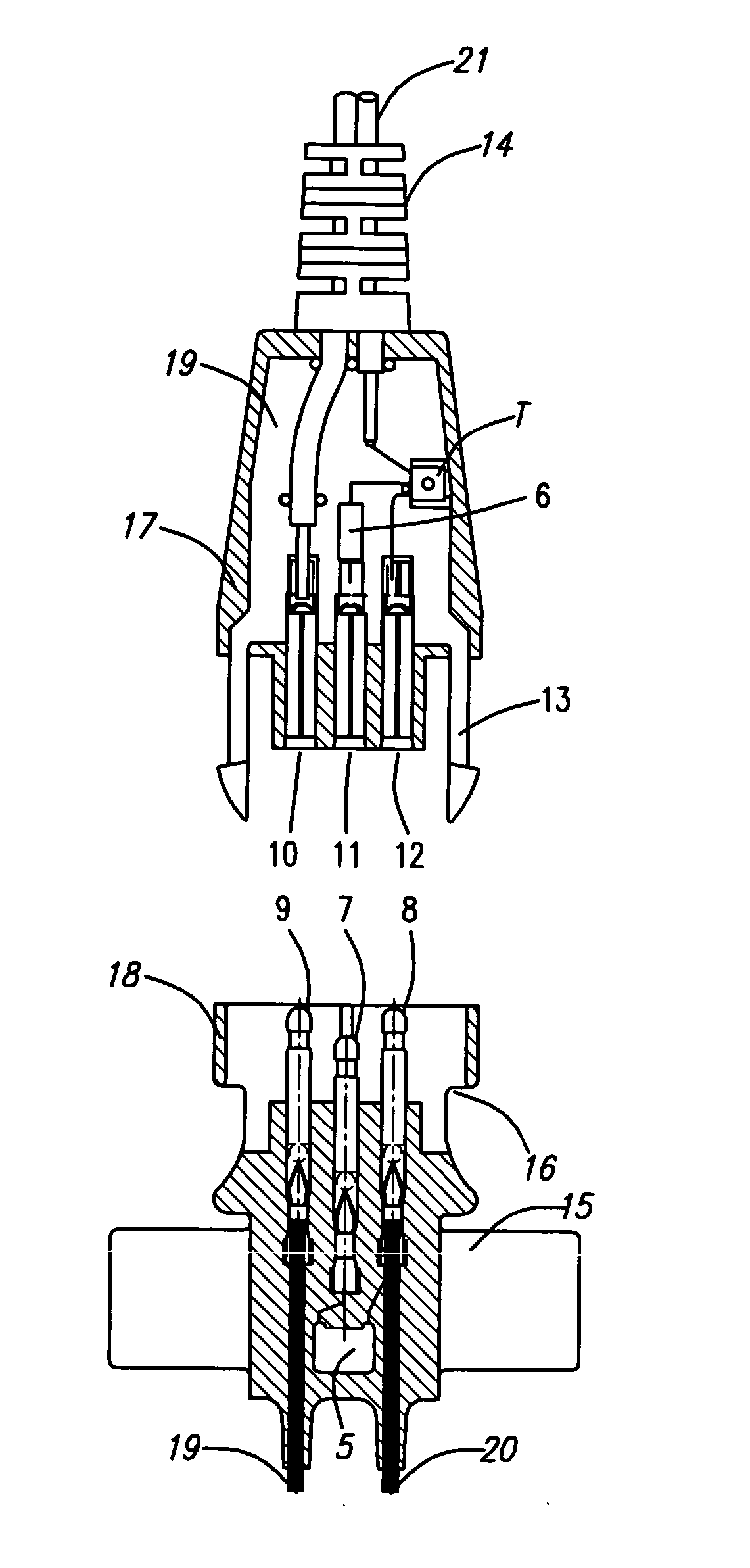

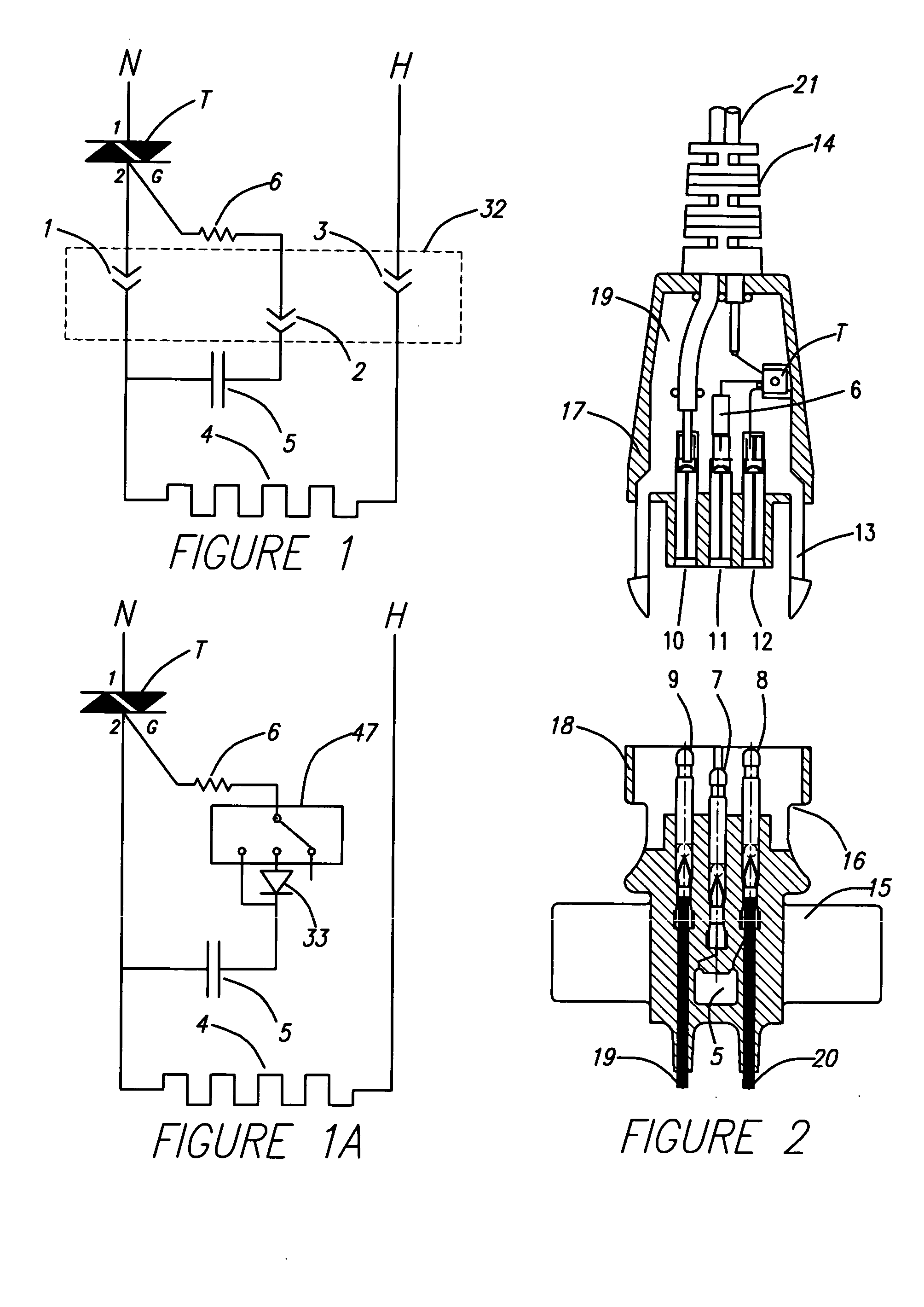

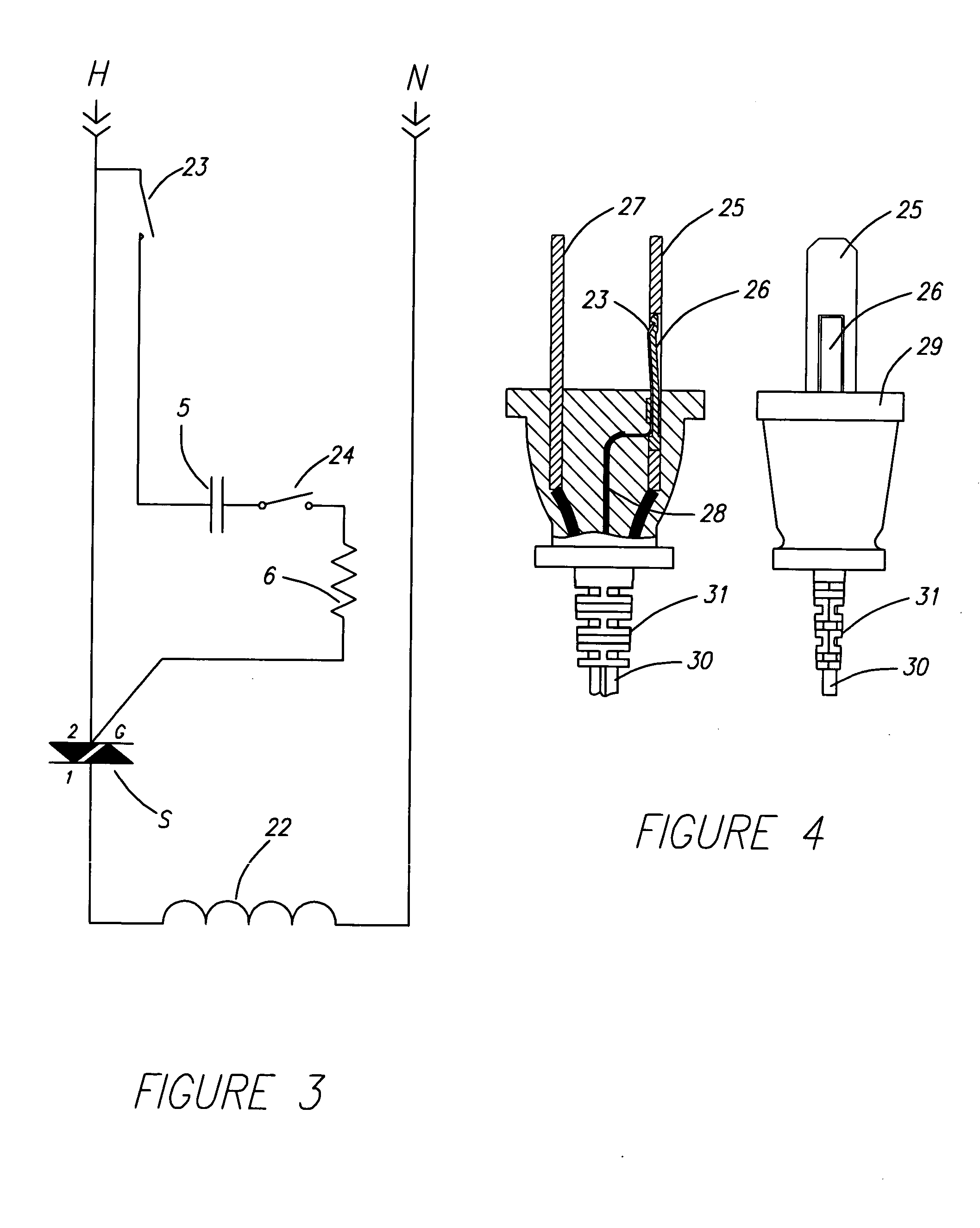

[0016] Referring to FIG. 1, a preferred embodiment of the invention will now be discussed. The load 4 is a resistance heating wire commonly used in heating pads. The power is switched on by a solid-state switch such as a triac, T, and is actively switched on every half cycle of a 60 Hertz 120 volt alternating current power source. The heating wire 4 has a resistance of 300 ohms and is 48 watts under full power. The triac T has a 1 amp rating and is preferably of the sensitive gate type requiring only 5 mA to turn on when supplied at the zero crossing of the AC supply voltage. The triac is shown on the neutral side of the supply. An alternate configuration with the triac on the hot, 120 VAC, side is also suitable. The heating pad controller, not shown, also switches the power on the neutral polarity. When 120 VAC is applied between the supply N and H, the power is not instantly turned on until sufficient gate current is introduced to the triac control gate TG which will occur at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com