Apparatus for manufacturing magnetic recording disk, and in-line type substrate processing apparatus

a technology of magnetic recording disk and processing apparatus, which is applied in the direction of magnetic layer protection, vacuum evaporation coating, transportation and packaging, etc., can solve the problems of abnormal film growth, affecting the adhesion strength of the lubricant layer, and increasing the demands of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0145] Next is described a magnetic disk manufacturing apparatus of the invention.

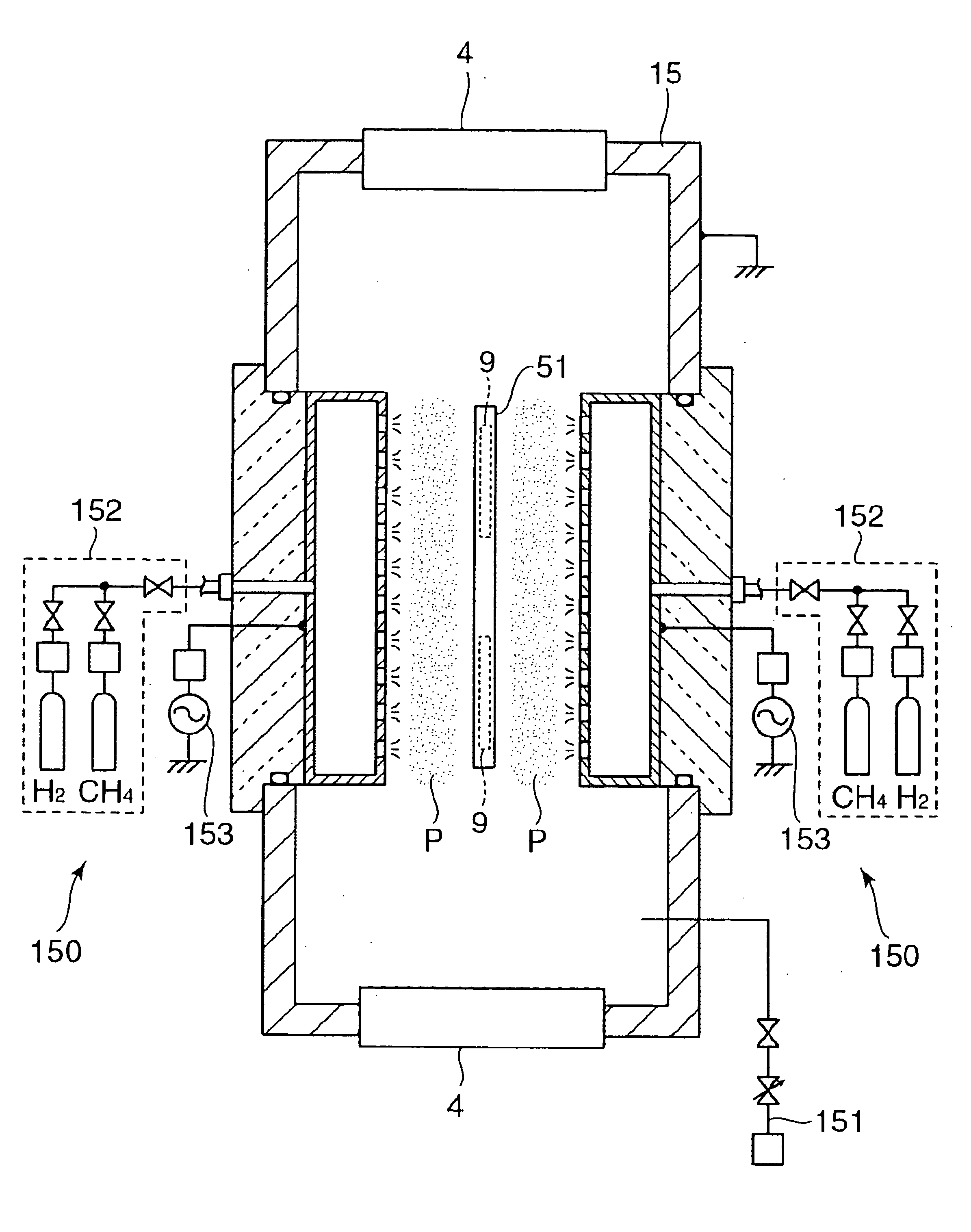

[0146]FIG. 15 shows a main part of the magnetic recording disk manufacturing apparatus of the second embodiment. The apparatus shown in FIG. 15 is different from the described first embodiment in the composition of the plasma-enhanced ashing to clean the substrate 9. Concretely, in the embodiment shown in FIG. 15, the ashing is carried out in the overcoat deposition chamber 15. FIG. 15 shows components on the overcoat deposition chamber 15.

[0147] The components on the overcoat deposition chamber 15 are nearly the same as those in FIG. 6, except the gas-introduction system 152. The gas-introduction 152 shown in FIG. 15 can introduce a gas mixture of carbon hydride and hydrogen, or an oxygen gas selectively to the overcoat chamber 15.

[0148] In FIG. 15, when an overcoat is deposited, a gas mixture of hydrocarbon and hydrogen is introduced. After the overcoat deposition, without moving the first substrat...

first embodiment

[0157] Description about the rotation mechanism 8 and the burnishing tape 212 are omitted because those are the same as in the described The lubricant coater 213 is mainly composed of an ejector 214 ejecting the lubricant from a tip thereof, a feeding tube 215 connected with the ejector 214, and a pump (not shown) that feeds the lubricant from a lubricant storing vessel (not shown) to the ejector 214 through the feeding tube 215. The lubricant coater 213 is provided at each side of the substrate location.

[0158] An operation of the burnishing-preparation chamber 210 is described.

[0159] In a state that the burnishing-preparation chamber 210 is pumped to obtain a specific vacuum pressure, the second substrate holder 52 holding the substrates 9 is moved into the burnishing-preparation chamber 210 and is stopped at a specific position. Then, the rotation mechanism 8 holds one of the substrates 9 and rotates it. During this rotation, the pressure members 247 at both sides of the substra...

fourth embodiment

[0175] Though the surface of the burnishing tape 242 is cleaned by the ion beam in this embodiment, it is possible to clean it by plasma or laser. It is also possible to clean the surface of the burnishing tape 242 using the method in the

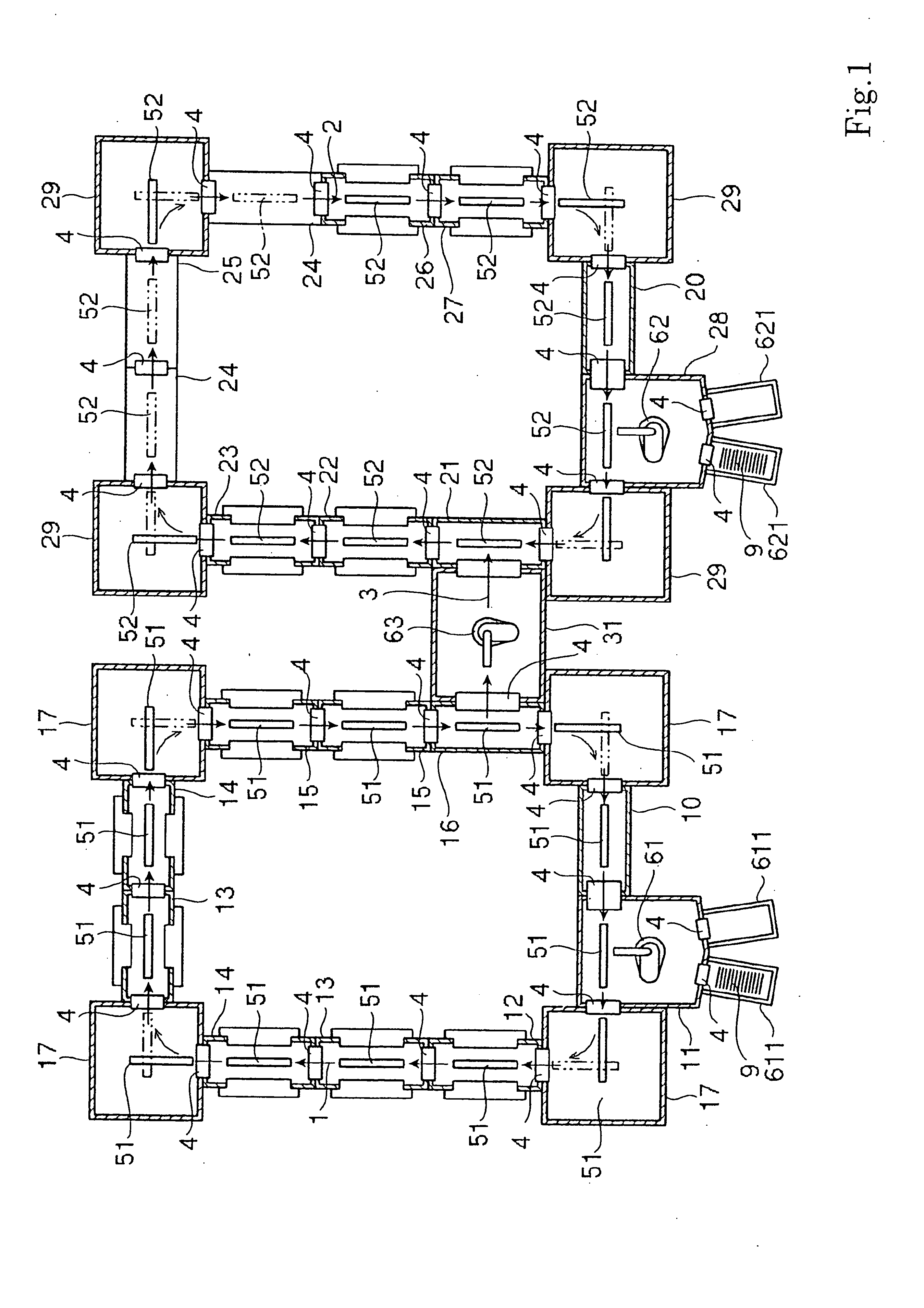

[0176] Next is described about an in-line type substrate processing apparatus of an embodiment of the invention. The magnetic-recording disk manufacturing apparatus shown in FIG. 1 is concurrently an in-line type substrate processing apparatus. The apparatus comprises a plurality of vacuum chambers 10-17, 20-29 connected along two circumventive transfer paths 1, 2, and the shifting robot 63 that transfers the substrate 9 in vacuum without exposing the substrate 9 to the atmosphere along the third transfer path 3 that interconnects the first path 1 and the second path 2.

[0177] The described structure is a kind of circumventive in-line type apparatus. U.S. Pat. No. 5,846,328 discloses the same kind of apparatus. This type of apparatus has a merit tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com