Transistor of semiconductor device, and method for manufacturing the same

a semiconductor device and transistor technology, applied in the direction of semiconductor devices, bulk negative resistance effect devices, electrical apparatus, etc., can solve the problems of short channel effect, leakage current generation, short channel effect, and almost double refresh time of dram, and achieve high device integration and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

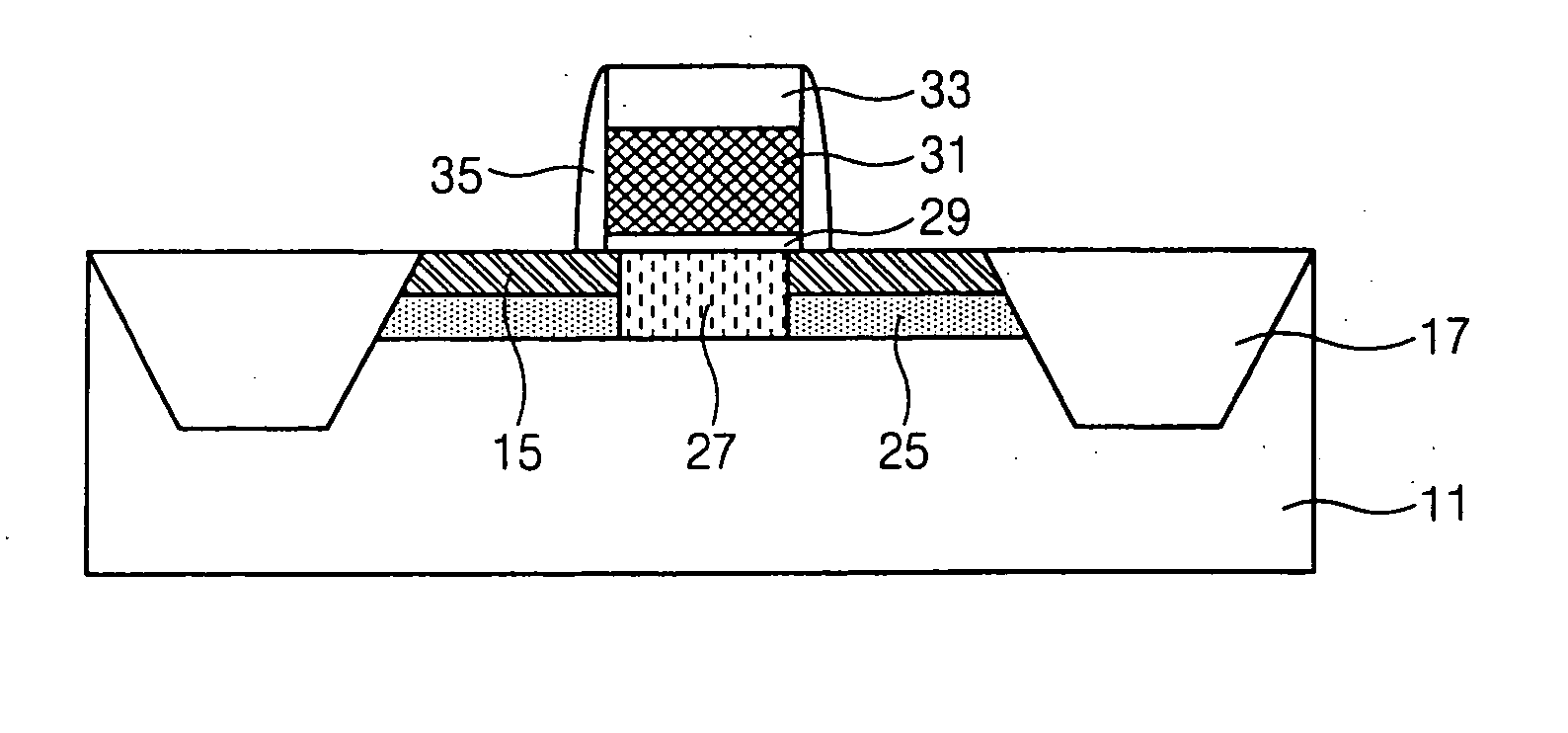

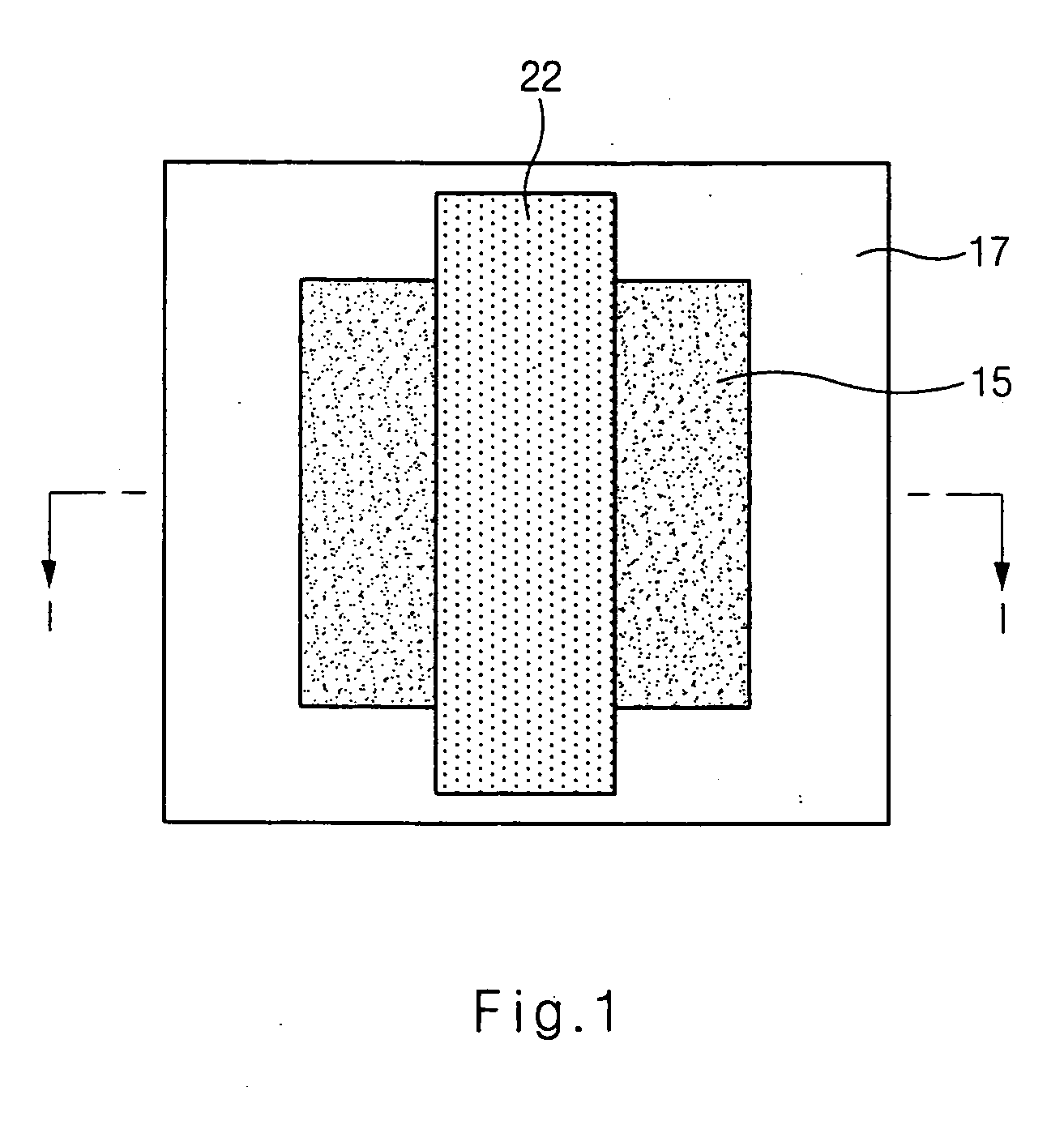

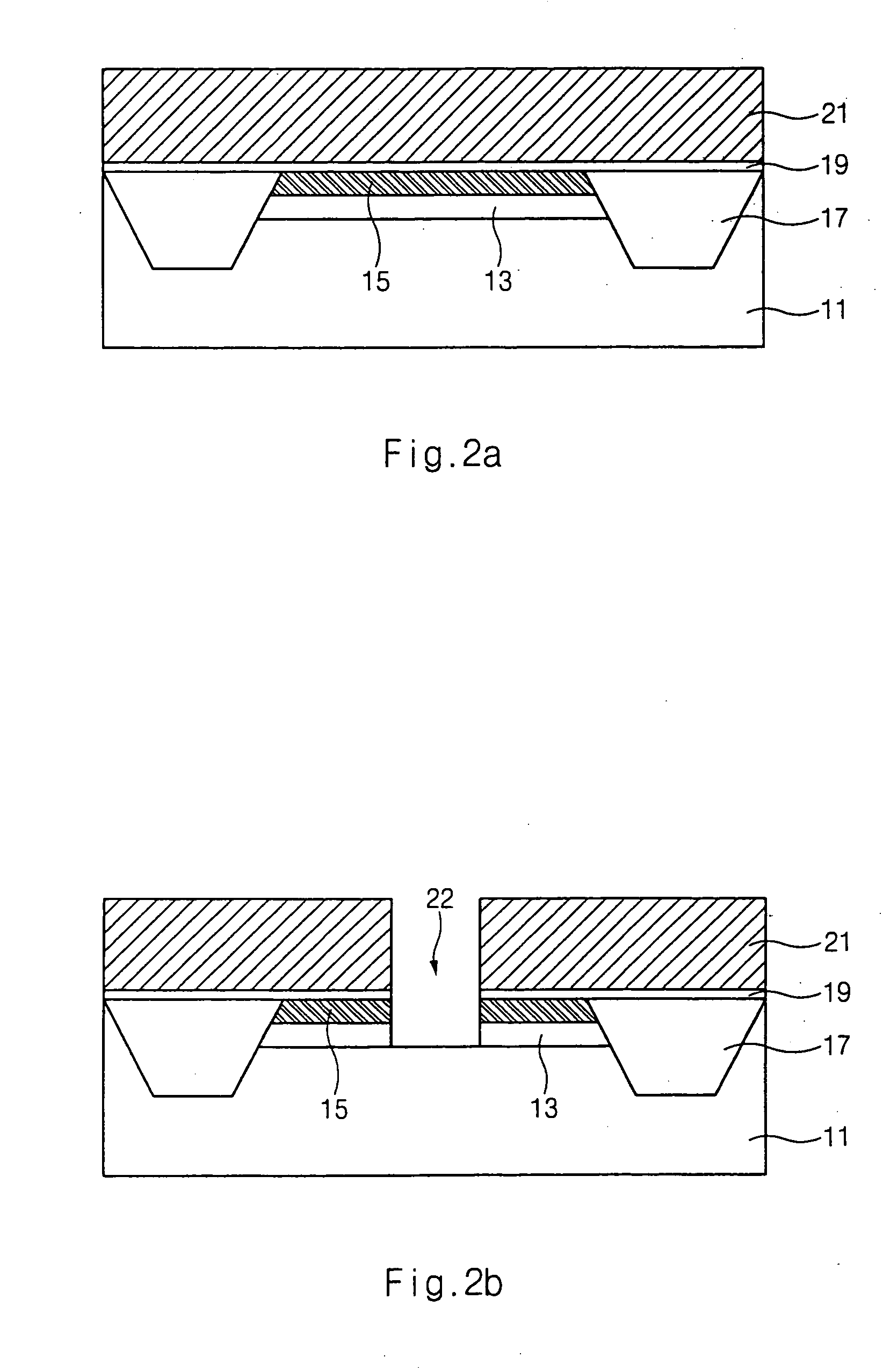

[0017]FIG. 1 is a layout diagram illustrating an active region and a gate electrode region 22 formed on a semiconductor substrate 11, and FIGS. 2a to 2f are cross-sectional diagrams illustrating sequential steps of a method for forming a transistor of a semiconductor device in accordance with the present invention, taken along lines I-I of FIG. 1.

[0018] Referring to FIG. 2a, an first epitaxial layer 13 and a conductive second epitaxial layer 15 are sequentially formed on the semiconductor substrate 11 consisting of silicon.

[0019] Preferably, the first epitaxial layer 13 is an epitaxial SiGe layer formed under an atmosphere of a mixture gas of a gas from the group consisting of GeH4, SiH4, SiH2Cl2 and combinations thereof, HCl and H2, and has a thickness ranging from 50 to 1000 Å, and the second epitaxial layer 15 is an epitaxial Si layer formed under an atmosphere of a gas from the group consisting of SiH4, SiH2Cl2 and combinations thereof, HCl and H2, and has a thickness ranging f...

second embodiment

[0038]FIGS. 3a to 3i are cross-sectional diagrams illustrating sequential steps of a method for forming a transistor of a semiconductor device in accordance with the present invention, taken along lines I-I of FIG. 1.

[0039] Referring to FIG. 3a, an first epitaxial layer 43 and a conductive second epitaxial layer 45 are sequentially formed on the semiconductor substrate 41 comprised of silicon. Preferably, the first epitaxial layer 43 is an epitaxial SiGe layer having a thickness ranging from 50 to 1000 Å formed under an atmosphere of a mixture gas of a gas from the group consisting of GeH4, SiH4, SiH2Cl2 and combinations thereof, HCl and H2, and the second epitaxial layer. 45 is an epitaxial Si layer having a thickness ranging from 50 to 1000 Å formed under an atmosphere of a mixture gas of a gas from the group consisting of SiH4, SiH2Cl2 and combinations thereof, HCl and H2.

[0040] A pad oxide film (not shown) and a nitride film (not shown) are sequentially formed on the entire sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com