Multilayer structures

a multi-layer structure and polyethylene technology, applied in the direction of weaving, pedestrian/occupant safety arrangements, vehicular safety arrangements, etc., can solve the problems of polyethylene films failing in several applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 16 to 24

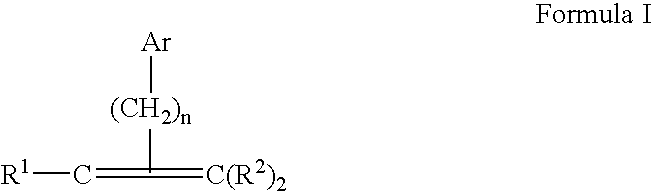

R

[0148] The coated fabrics of Examples 16 through 24 find use in artificial leather.

example 16

[0149] Example 15 repeated except that the polymer formulation does not contain Silcat R and ATH, but includes 11.4 parts of Perkadox 14S and 5 parts of Perkalink 300. The polymer formulation is applied onto FAB3 as described in Example 15. A standard mat lacquer is applied. Subsequently the polymer coating is foamed in an oven at 200° C. during 2 minutes. The foamed structure is then embossed in a hot platen press at about 100° C.

example 17

[0150] 80 parts of ESI-6 are blended with 20 parts of Affinity HF 1030 polyolefin plastomer. This blend is mixed with 8 parts of ultra fine calcium carbonate, 2 parts of titanium dioxide, 2 parts of Perkadox 14S, 2 parts of Porofor ADC LC2, 0.1 parts of Irganox B225, 0.5 parts of zinc stearate, 0.5 parts of zinc oxide, and I part of stearic acid. This formulation is coated onto FAB3, a mat lacquer is applied to the resulting coating and the coating is foamed as described in Example 15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com