Spiral wound laminate wood and method for construction

a technology of spiral wound and laminate wood, applied in the field of wood products, to achieve the effect of strong laminate bonding, low axial force, and minimal thickness of glu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description, various embodiments of the present invention will be described. For purposes of explanation, specific configurations and details are set forth in order to provide a thorough understanding of the embodiments. However, it will also be apparent to one skilled in the art that the present invention may be practiced without the specific details. Furthermore, well-known features may be omitted or simplified in order not to obscure the embodiment being described.

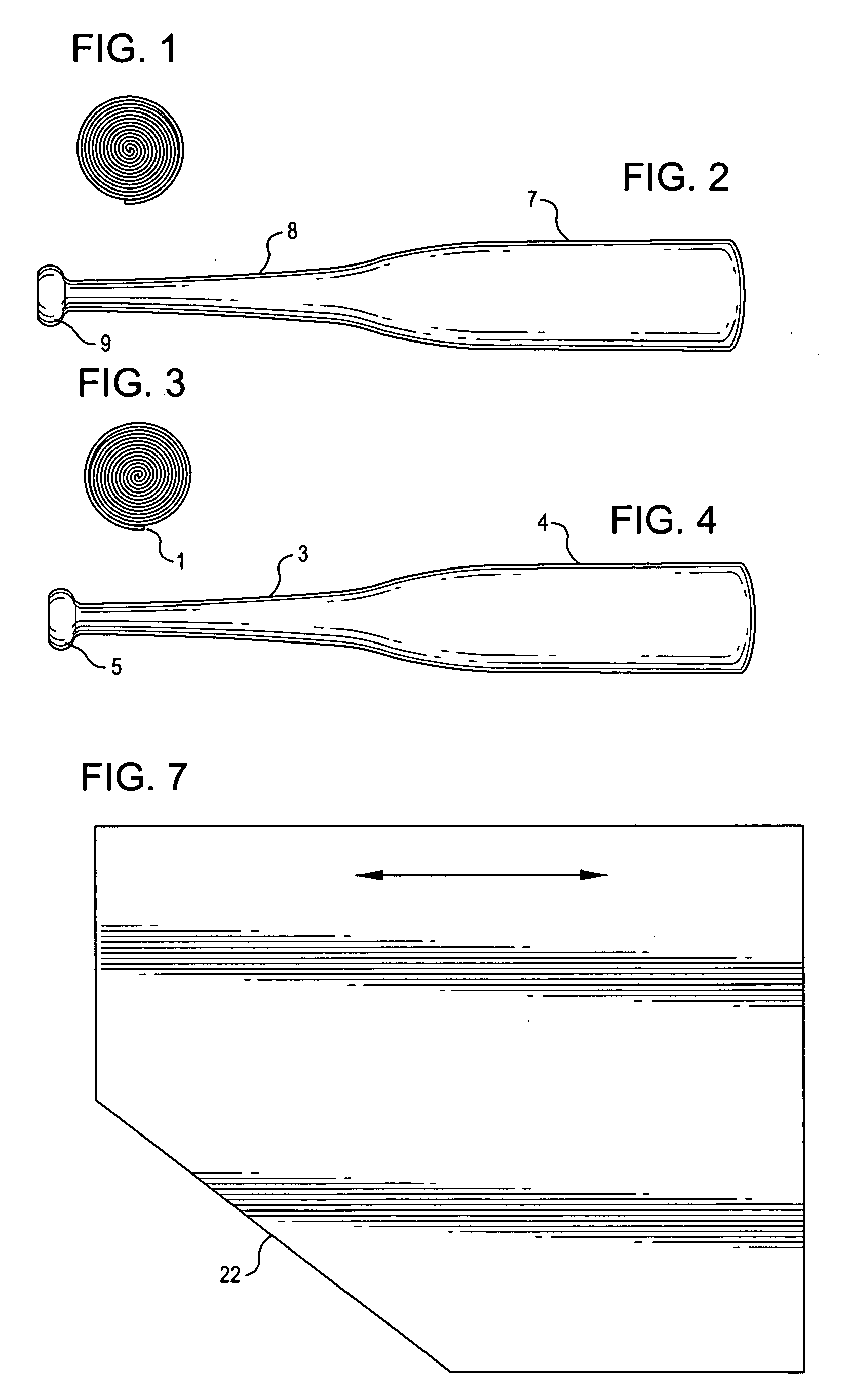

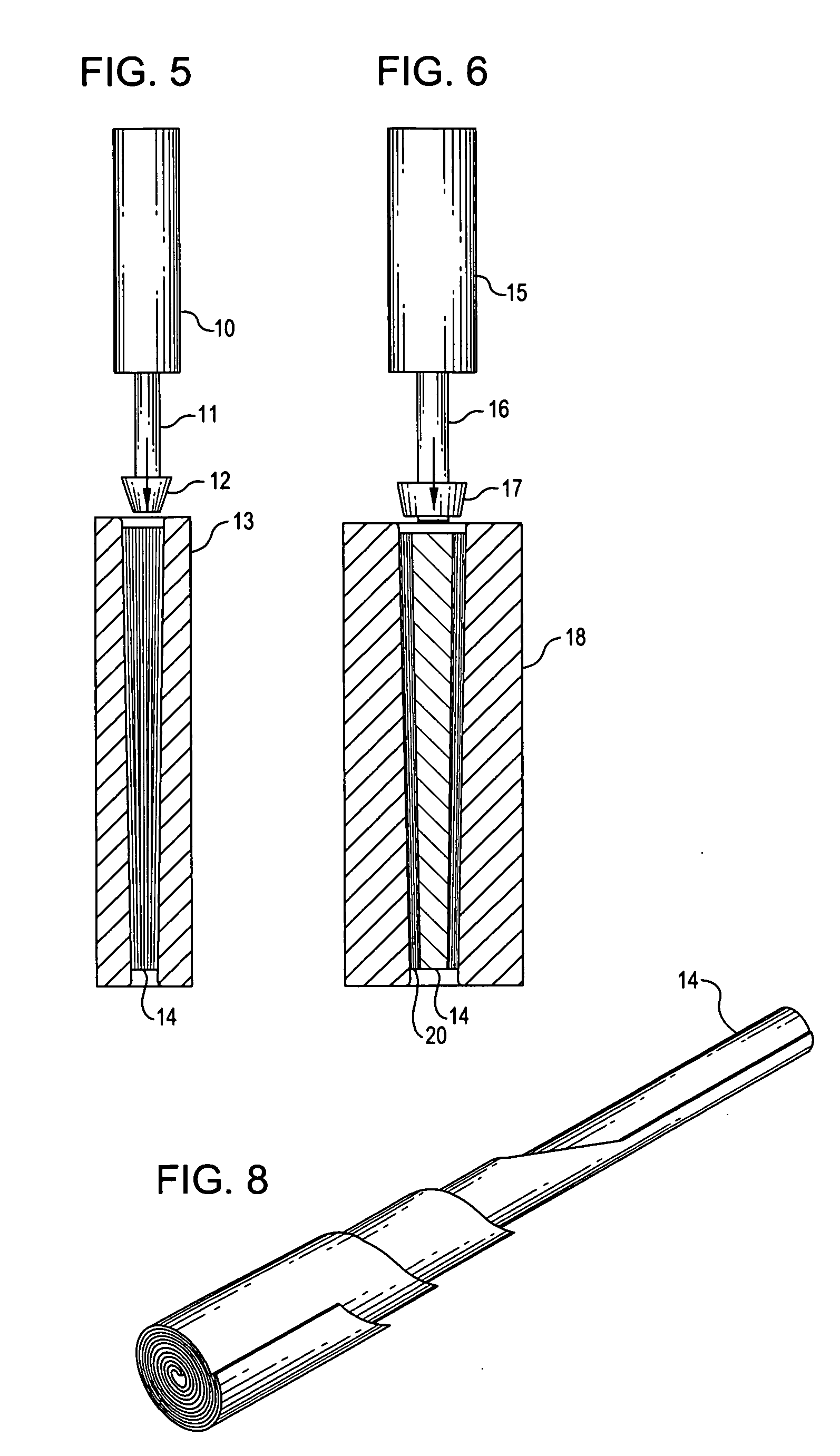

[0035] The spiral wound bat or other implement will be constructed of either a single or multiple veneer sheet(s) 22 of varying thicknesses wound in a very tight spiral pattern 14 as illustrated in FIGS. 7 and 8. For ease of description, one sheet will be referenced throughout this disclosure. The veneer sheet can be cut at an angle 22 to create a slightly tapered profile 21 when rolled. The veneer sheet is then coated with a common glue, binder, epoxy or thermal set resin, rolled 14, and placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com