Two-layer protective coating system for LCD glass

a coating system and glass technology, applied in coatings, transportation and packaging, chemical instruments and processes, etc., can solve the problems of glass surface quickly becoming contaminated, contamination being observed, rendering glass useless for many applications, etc., to improve the scratch resistance of the coating system, evaluate the cleanness of the glass surface, and the effect of the same chemistry and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0141] Two coating systems were tested in this example, both using polymers that are more hydrophobic than starch as the second protective coating over a starch first protective coating.

[0142] In this example, the first coating composition had a concentration of starch of 10%. The two second coating compositions used in this example were (i) a styrene / acrylic co-polymer based emulsion (20% solids) available from Johnson Wax Professional, Sturtevant, Wiss., and (ii) Chempeel WB high solids (55-60%) strippable coating product available from PPG Industries, One PPG Place, Pittsburgh, Pa., respectively.

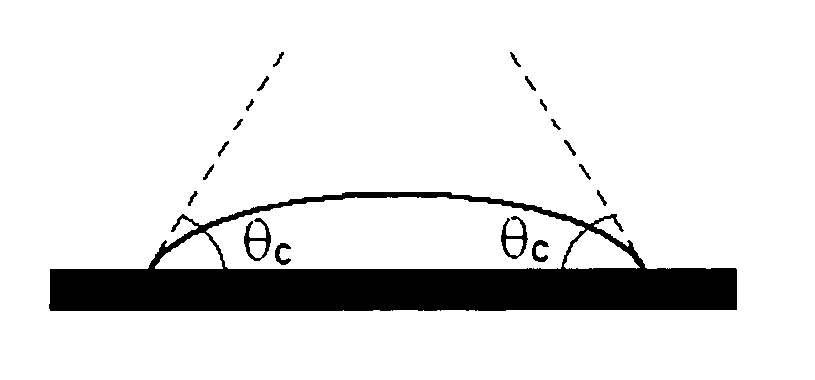

[0143] The first protective coating was formed as discussed above. After the first coating dried up, the second coating composition was applied to the surface of the first protective coating layer and dried with an IR heater to form a second protective coating layer. Water contact angle was then measured on the surface of the second protective coating layer thus obtained and recorded as...

example 2

[0145] One coating system was tested in this example, using petrolatum as the second protective coating over a starch first protective coating.

[0146] In this example, the first coating composition has a concentration of starch of 5%. The second coating composition used in this example was petrolatum gel available from Fisher Scientific, Pittsburgh, Pa.

[0147] The first protective coating was formed as discussed above. The thickness of the dried first protective coating was about 1 μm. After the first coating dried up, the second coating composition (petrolatum gel) was applied to the surface of the first protective coating layer by smearing to form a second protective coating layer. Water contact angle was then measured on the surface of the second protective coating layer thus obtained and recorded as the first water contact angle θ1 in TABLE I.

[0148] Half of the glass sheet was then subjected to water treatment by dipping and immersion in deionized water for 1 minute. Coating th...

example 3

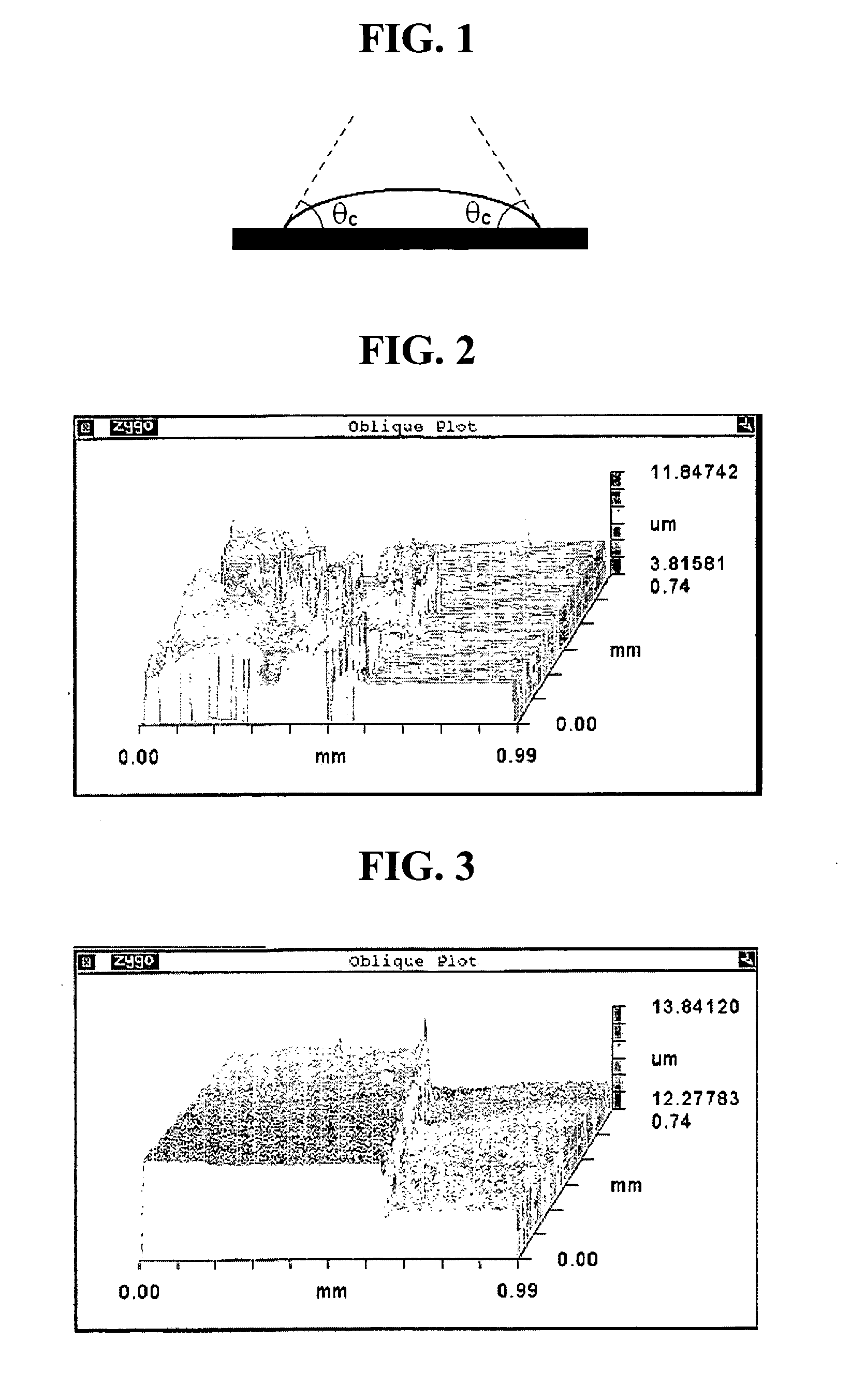

[0152] Two coating systems were tested in this example, both using polymer beads as the second protective coating over a starch first protective coating.

[0153] In this example, the first coating composition has a concentration of starch of 10%. The second coating composition used in this example was (iii) poly(styrene-divinylbenzene) (PSDB, 20% divinyl benzene, average molecular weight 250,000 g / mol) beads and (iv) poly(methyl methacrylate) (PMMA, average molecular weight 25,000 g / mol) beads, respectively, both available from Polysciences, Inc., Warrington, Pa.

[0154] The first protective coating was formed as discussed above. Once the first coating composition was applied to the hot glass surface and before it dried up, the glass sheet was placed horizontally and the second coating composition (iii) or (iv) was applied to the surface of the first protective coating layer by sprinkling. After the coating dried up, excessive loose polymer beads were removed by flipping the glass she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| Rms surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com