Polymer composite baseball bat endcap

a composite and baseball bat technology, applied in the field of baseball bats, can solve the problems of not exceeding the standards of regulatory bodies, and achieve the effects of improving bat control, reducing weight, and increasing bat speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

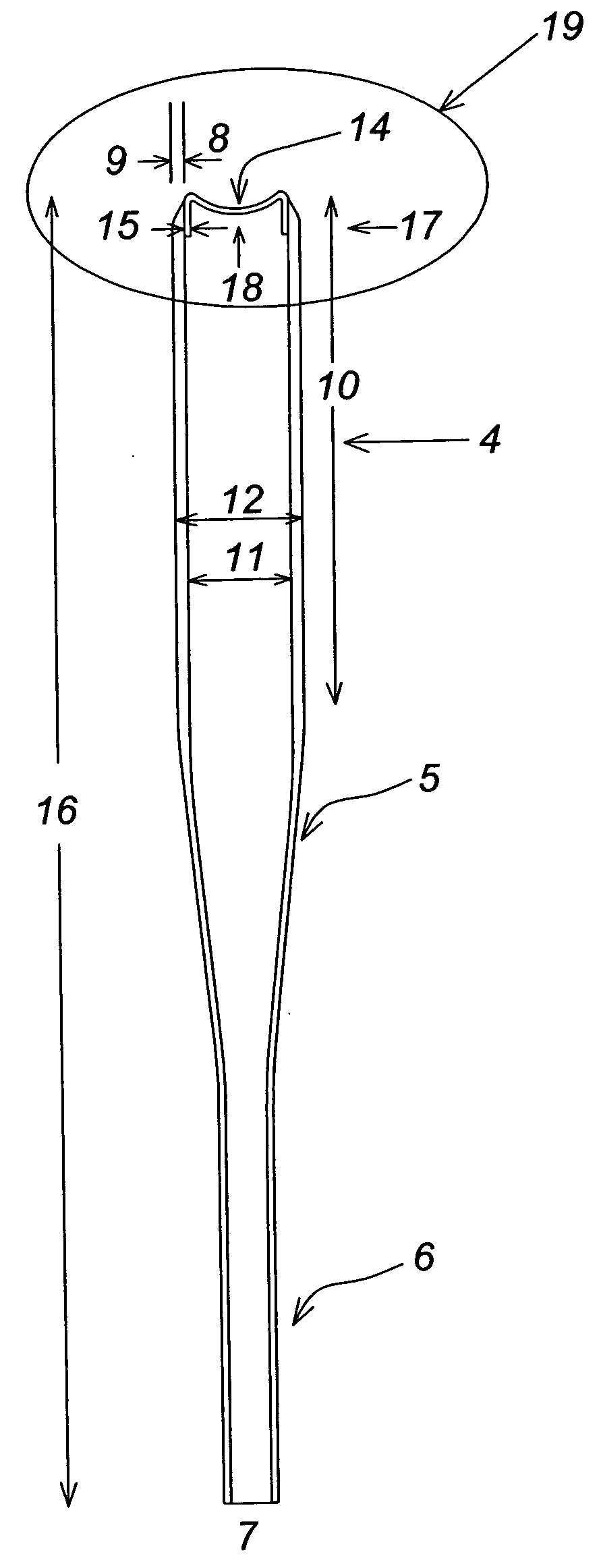

[0039] A typical prior bat endcap is shown in FIG. 1. Such typical prior art endcaps are made of polymer or metal and are of relatively complex geometry (e.g. ribs 1, lugs 2, grooves 3, etc.). They require expensive tooling, and generally require urethane added to the entire interior 18 of the endcap 14 to aid in fastening the endcap to the barrel end, such urethane increasing the barrel end weight. Typically, such prior bat endcaps of FIG. 1 weigh in excess of 1.5 ounces and the urethane adds an additional 1.5 ounces or more for a total added barrel end weight of at least 3 ounces.

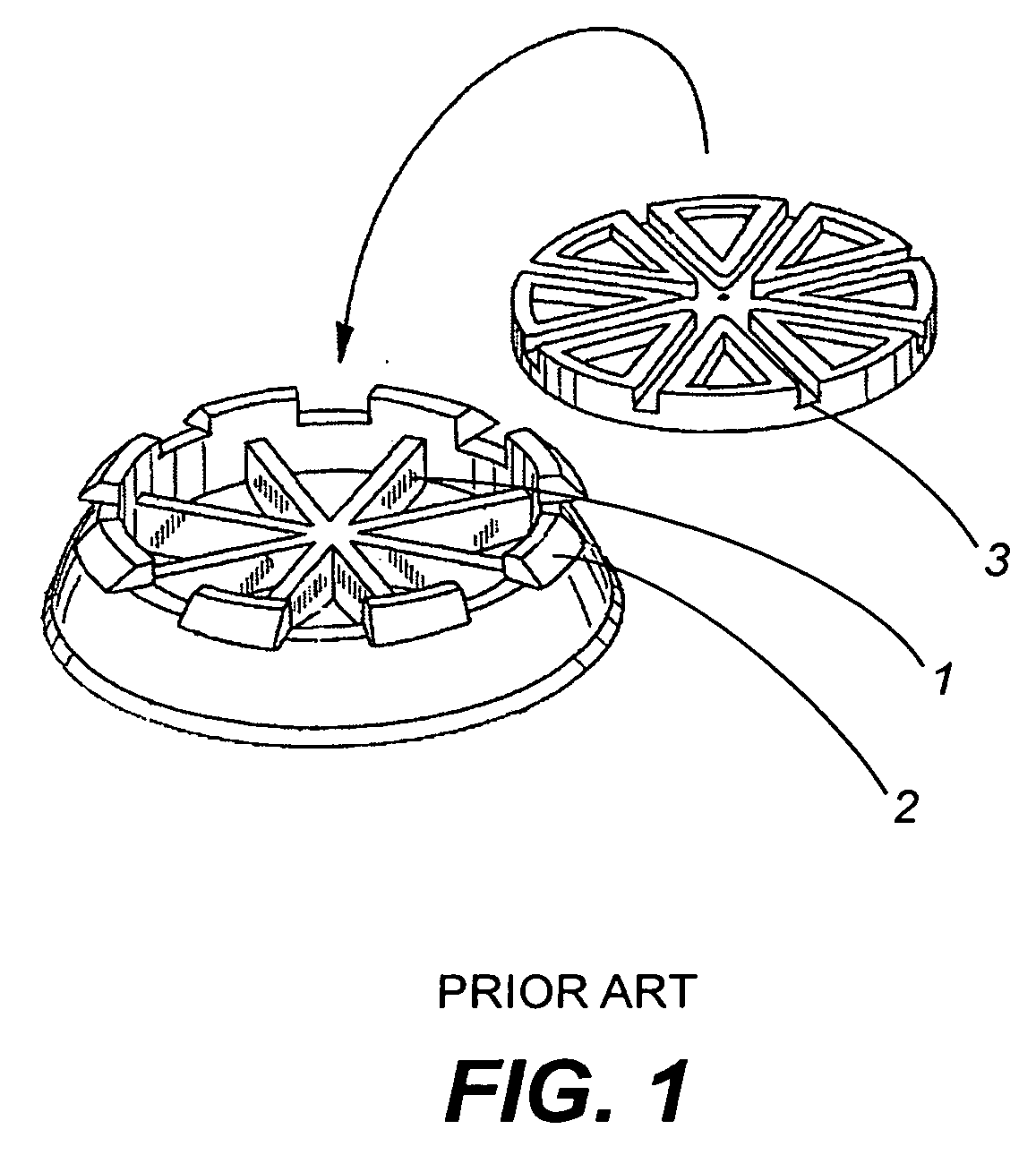

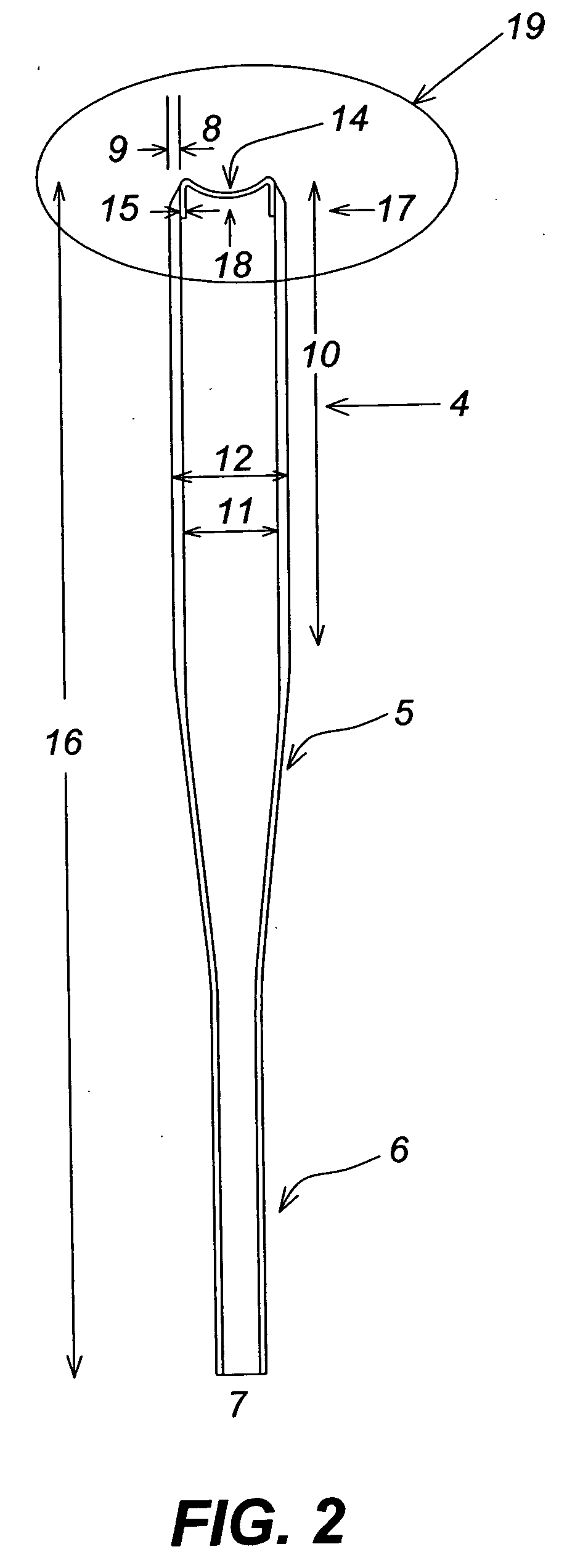

[0040] All tubular baseball bats consist of a barrel or hitting portion 4, a handle or gripping portion 6, with a tapered section 5 joining the barrel portion 4 and gripping portion 6. These parts are shown in FIG. 2. Though not shown in FIG. 2, all tubular metal bats include a traditional knob at the extreme handle end portion 7 which serves to close off the handle end 7 and to prevent the players hands...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com