Fluid actuating apparatus and method for manufacturing a fluid actuating apparatus, and electrostatically-actuated fluid discharge apparatus and process for producing an electrostatically-actuated fluid discharge apparatus

a technology of fluid actuating and fluid discharge, which is applied in the direction of chairs, applications, coatings, etc., can solve the problems of lack of repulsion force, and achieve the effects of suppressing power consumption, increasing thickness, and strengthening the support pos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

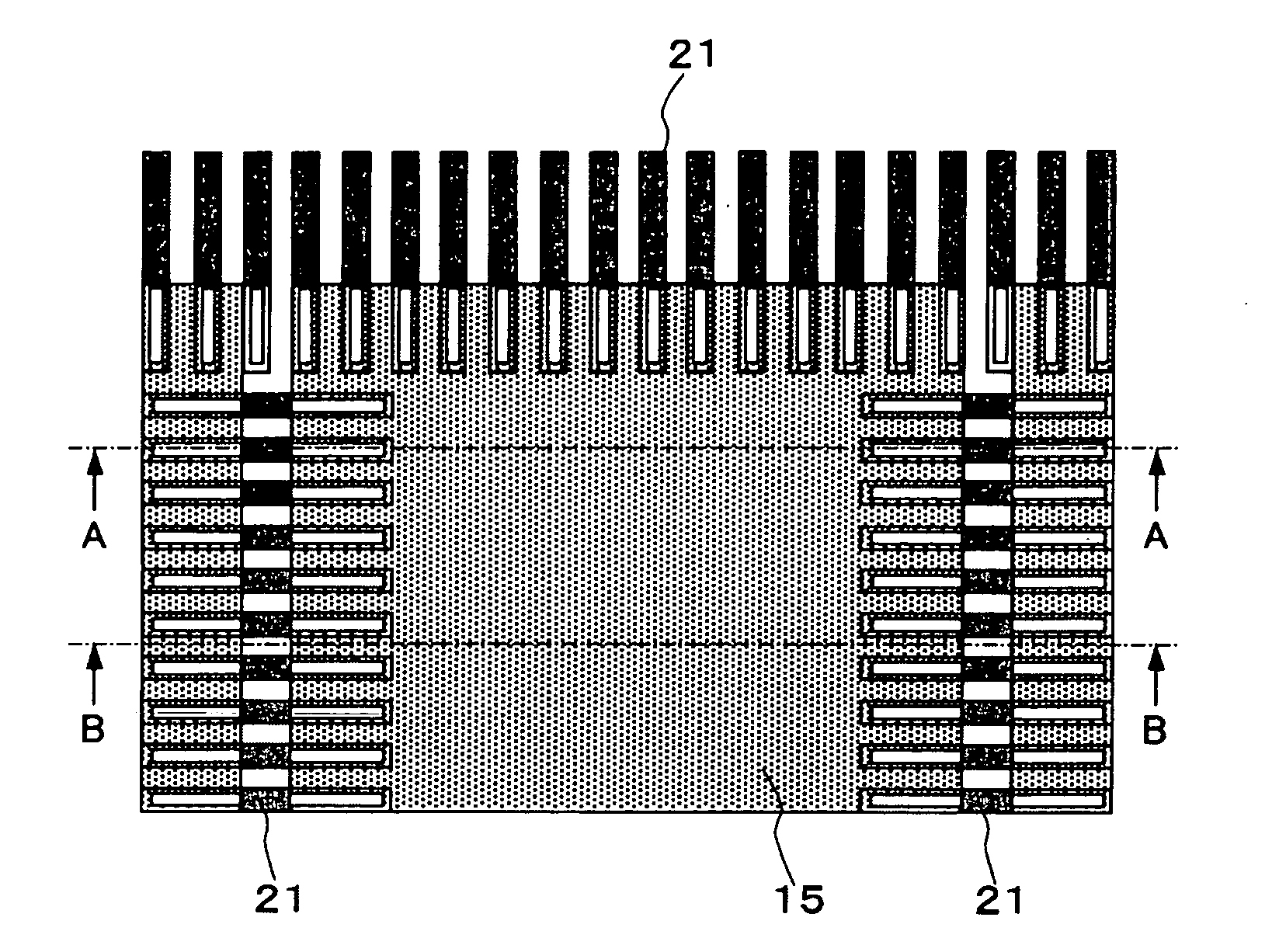

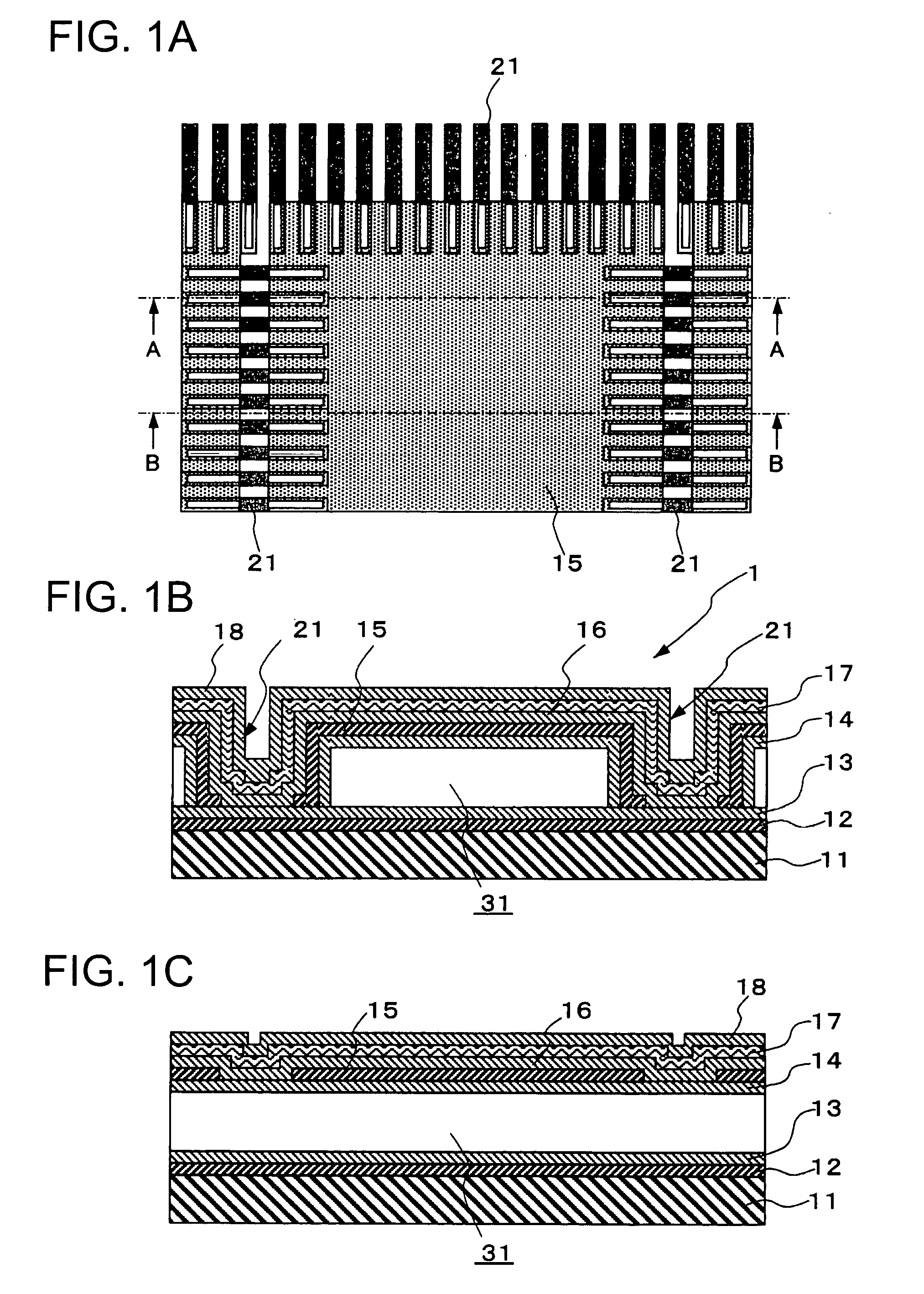

[0067] The fluid actuating apparatus according to the first embodiment of the present invention will be described with reference to FIGS. 1A-1C. FIG. 1A shows part of a plan view of the layout, FIG. 1B shows a diagrammatic cross-sectional structure taken along the line A-A of FIG. 1A, and FIG. 1C shows a diagrammatic cross-sectional structure taken along the line B-B of FIG. 1A. The scale of FIG. 1A and that of FIG. 1B, FIG. 1C are not the same. Fluid actuating apparatuses are actually arranged in a line, but the figures show a single fluid actuating apparatus, which is described below.

[0068] As shown in FIGS. 1A-1C, a substrate-side electrode 12, which includes a conductor thin film and which is common to another fluid actuating apparatus (not shown), is formed on a substrate 11 having at least a surface formed from an insulating layer. A first insulating film 13 is formed on the substrate-side electrode 12. A second insulating film 14 is formed on the first insulating film 13 so ...

example 2

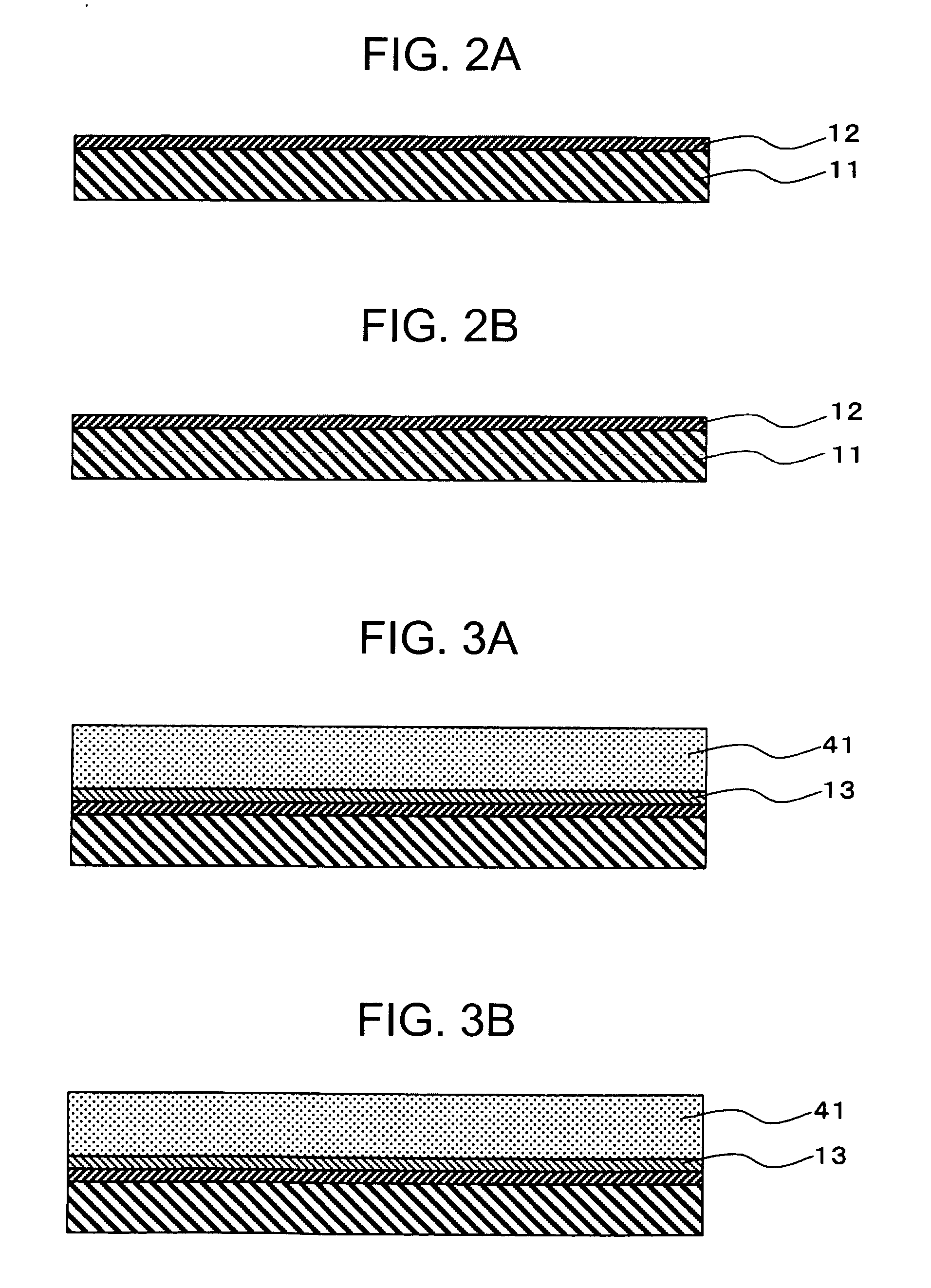

[0079] The method for producing a fluid actuating apparatus according to the first embodiment of the present invention will be described with reference to the views of FIGS. 2A to 12B showing the steps in the production process. The views of FIGS. 2A to 12B showing the steps in the production process mainly show cross-sectional structures at positions similar to the positions of the cross-section taken along the line A-A and the cross-section taken along the line B-B shown in the plan view of the layout of FIG. 1A. In FIGS. 4A-4C, a plan view of the layout of the sacrifice layer pattern is also shown.

[0080] As shown in FIGS. 2A-2B, a substrate 11 having at least an insulating surface is prepared. As the substrate 11, for example, in the present Example, a substrate comprising an insulating film, e.g., a silicon oxide film formed on a silicon substrate is used. A common substrate-side electrode 12 is formed on the substrate 11. In the present Example, the substrate-side electrode 12...

example 3

[0096] Next, the electrostatically-actuated fluid discharge apparatus according to the first embodiment of the present invention will be described with reference to the diagrammatic perspective view of FIG. 13 and the diagrammatic cross-sectional views of FIGS. 14A-14B. In this Example, an electrostatic head is described as an example of the electrostatically-actuated fluid discharge apparatus using the fluid actuating apparatus of the present invention.

[0097] First, as shown in FIG. 13, an electrostatically-actuated fluid discharge apparatus (electrostatic head) 1 according to the present embodiment comprises a fluid actuating apparatus 2 comprising a plurality of diaphragms 17 actuated (vibrated) by electrostatic force, which diaphragms are arranged in a line with high density, and a so-called fluid feed zone 55 comprising a partition structure 54 which is disposed above the diaphragms 17 at the corresponding position, and which has formed therein a pressure chamber (so-called ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com