Microfluidic devices for electrophoretic analysis of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

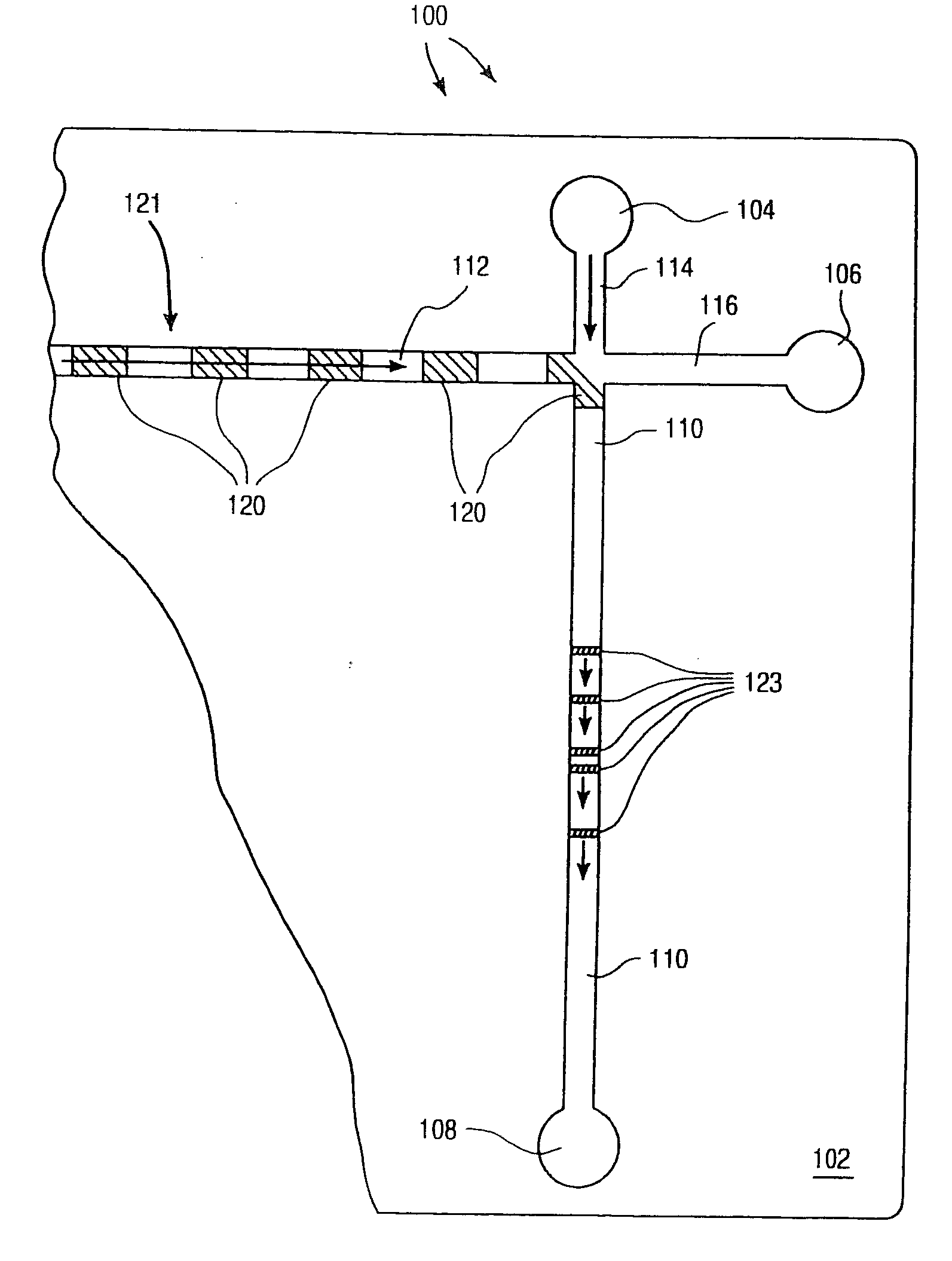

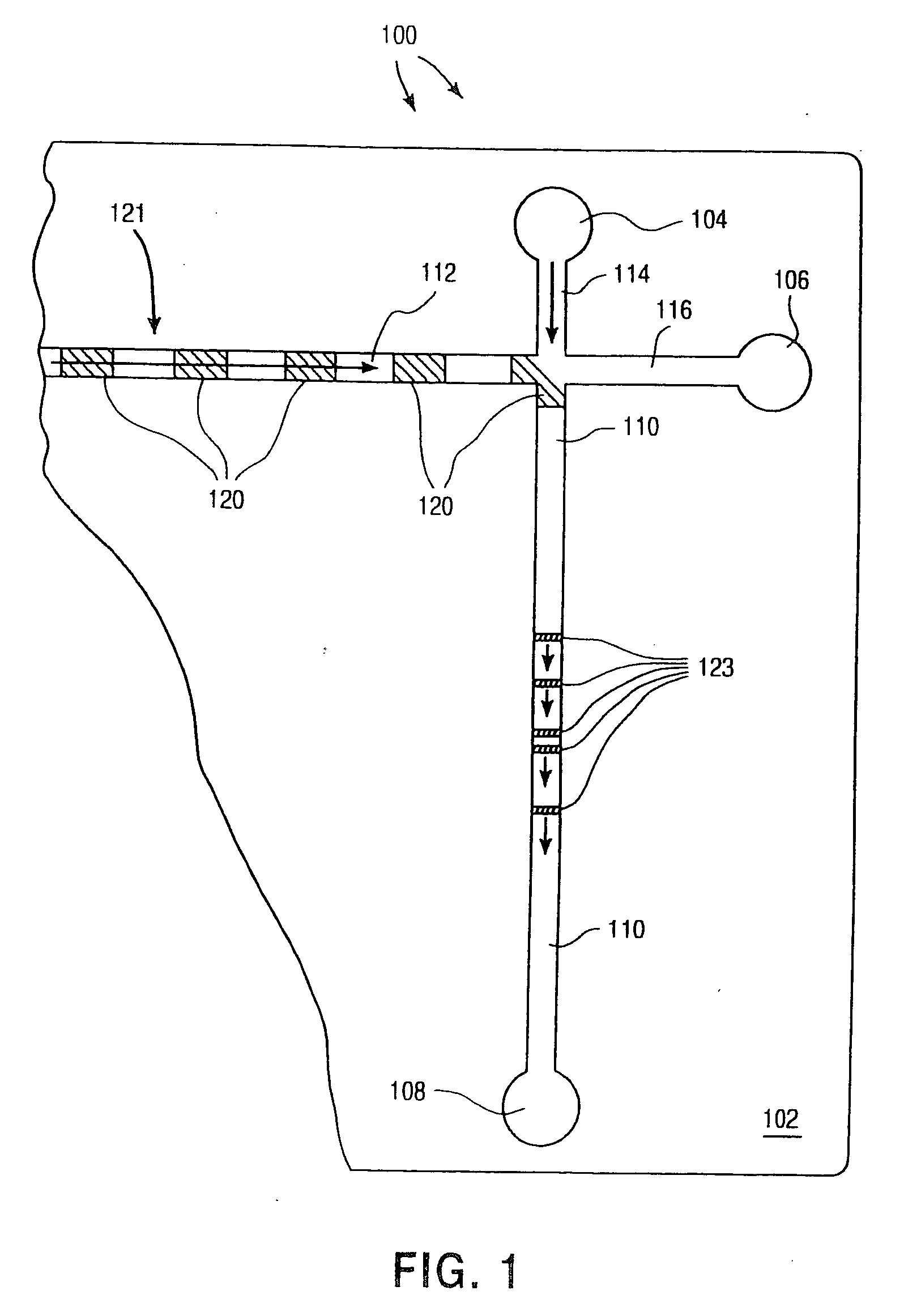

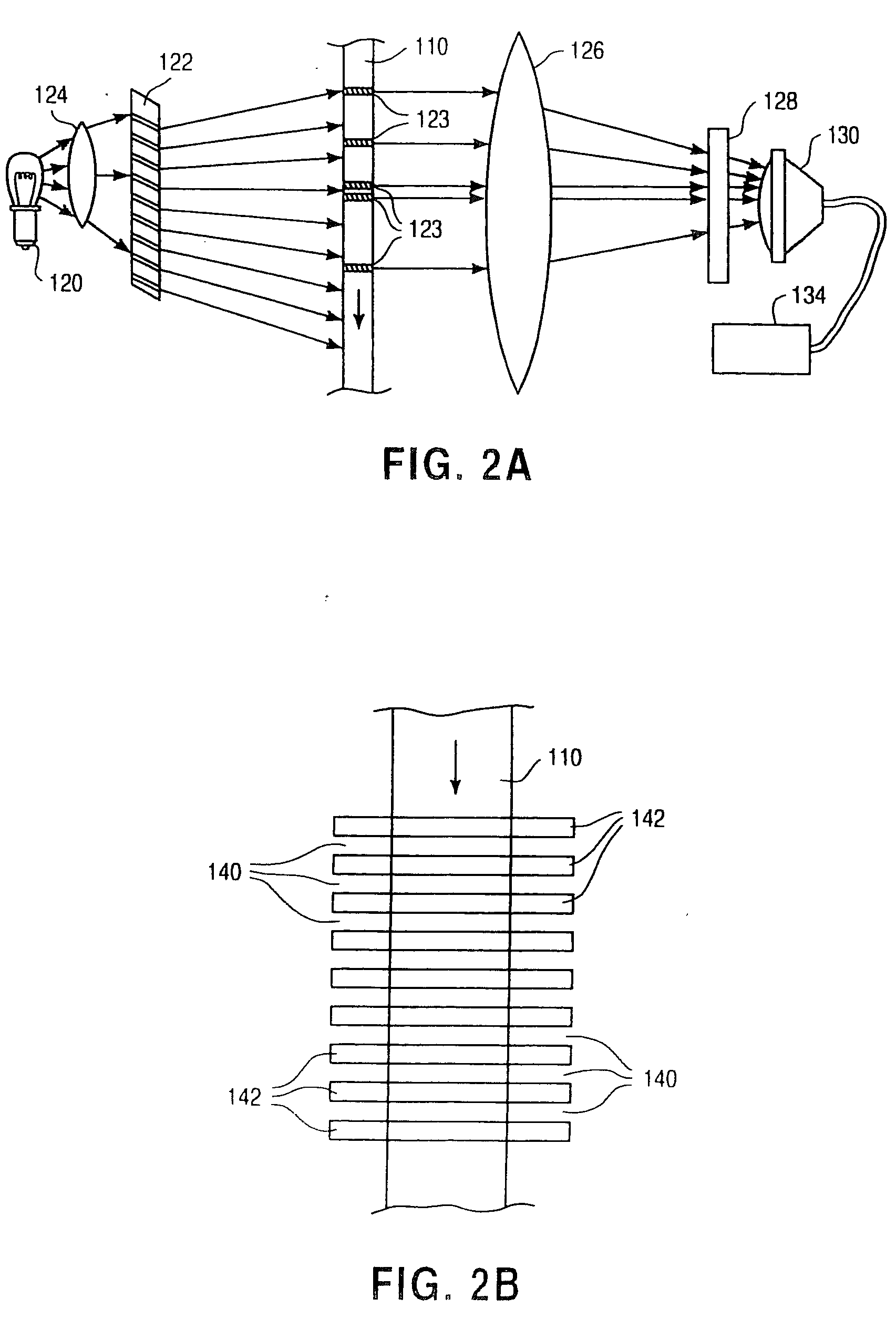

[0014] General Description of Microfluidic Systems

[0015]FIG. 1 discloses a representative diagram of an exemplary microfluidic system 100 according to the present invention. As shown, the overall device 100 is fabricated in a planar substrate 102. Suitable substrate materials are generally selected based upon their compatibility with the conditions present in the particular operation to be performed by the device. Such conditions can include extremes of pH, temperature, salt concentration, and application of electrical fields. Additionally, substrate materials are also selected for their inertness to critical components of an analysis or synthesis to be carried out by the system.

[0016] Useful substrate materials include, e.g., glass, quartz and silicon, as well as polymeric substrates, e.g., plastics. In the case of conductive or semiconductive substrates, there should be an insulating layer on the substrate. This is particularly important where the device incorporates electrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com