Methods for obtaining thermostable enzymes, DNA polymerase I variants from Thermus aquaticus having new catalytic activities, methods for obtaining the same, and applications of the same

a technology of thermostable enzymes and dna polymerase i, which is applied in the field of methods for obtaining thermostable enzymes, can solve the problems of affecting the fidelity of enzymes, critical limitation of enzymes, and overall inconvenien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

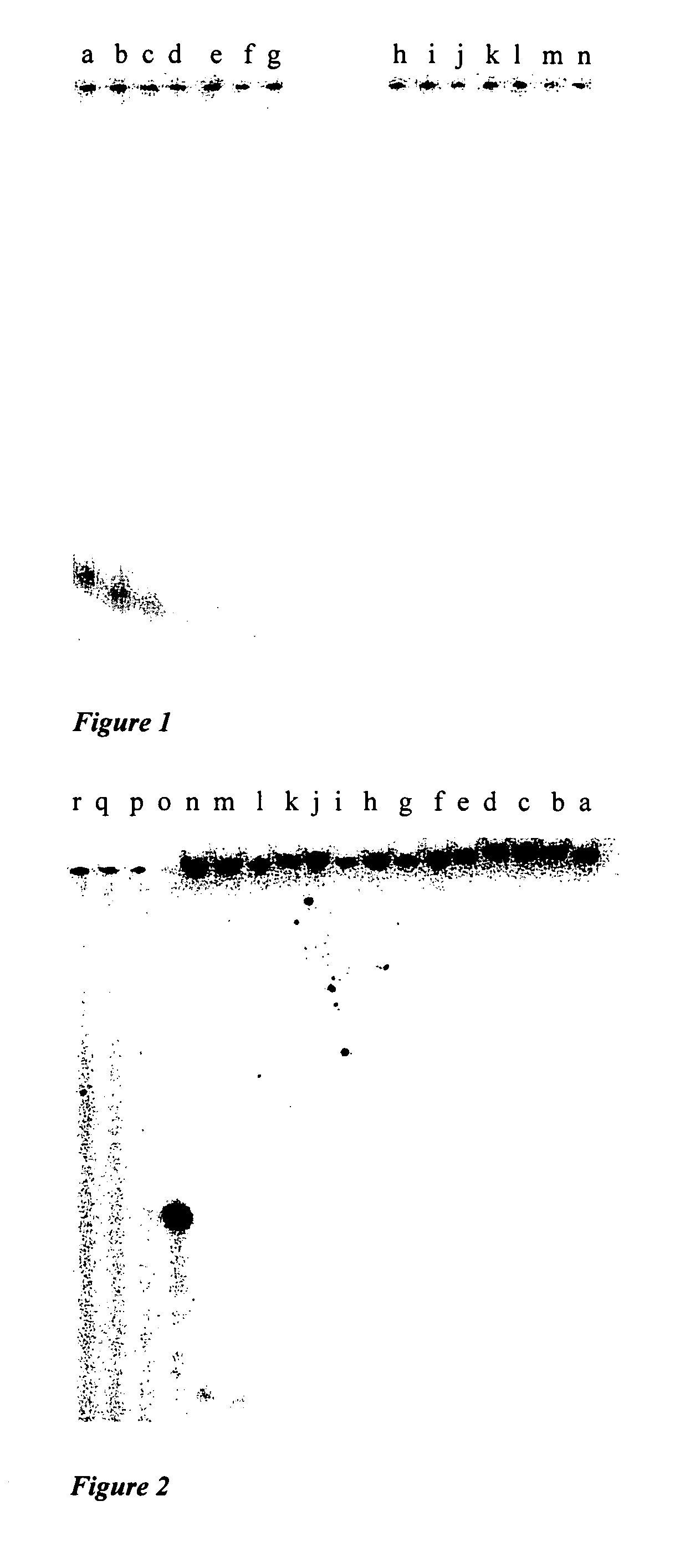

Polyclonal Phage-Polymerases (FIG. 1)

[0216] In this example, the reverse transcriptase activity of phage-polymerases was assessed as obtained after different rounds of selection in the presence of Mg2+ or Mn2+ ions. In these experiments, two reverse transcription (RT) mixes were used. The final concentration of each component in a reaction was: 10 μM RNA (SEQ ID NO: 12); 5 μM DNA (SEQ ID NO: 13); 0.25 mM dNTP; 3 mM MgCl2 or 2.5 mM MnCl2.

[0217] Each 1.9 μl aliquot of the reaction mix was further added to 15 μl of phage-polymerases (108 particles) after a given selection round heated for 5 min at 65° C. The solutions were then incubated at 37° C. for 15 min. The reactions were stopped by adding 15 μl of EDTA / formamide containing denaturation solution, heating for 3 min. at 94° C., and placed on ice. The incorporation of alpha 32P-dTTP was determined on 20% polyacrylamide gel; 15 μl of the final reaction volume were loaded.

[0218] The lane designations in FIG. 1 are as follows:

MnCl...

example 2

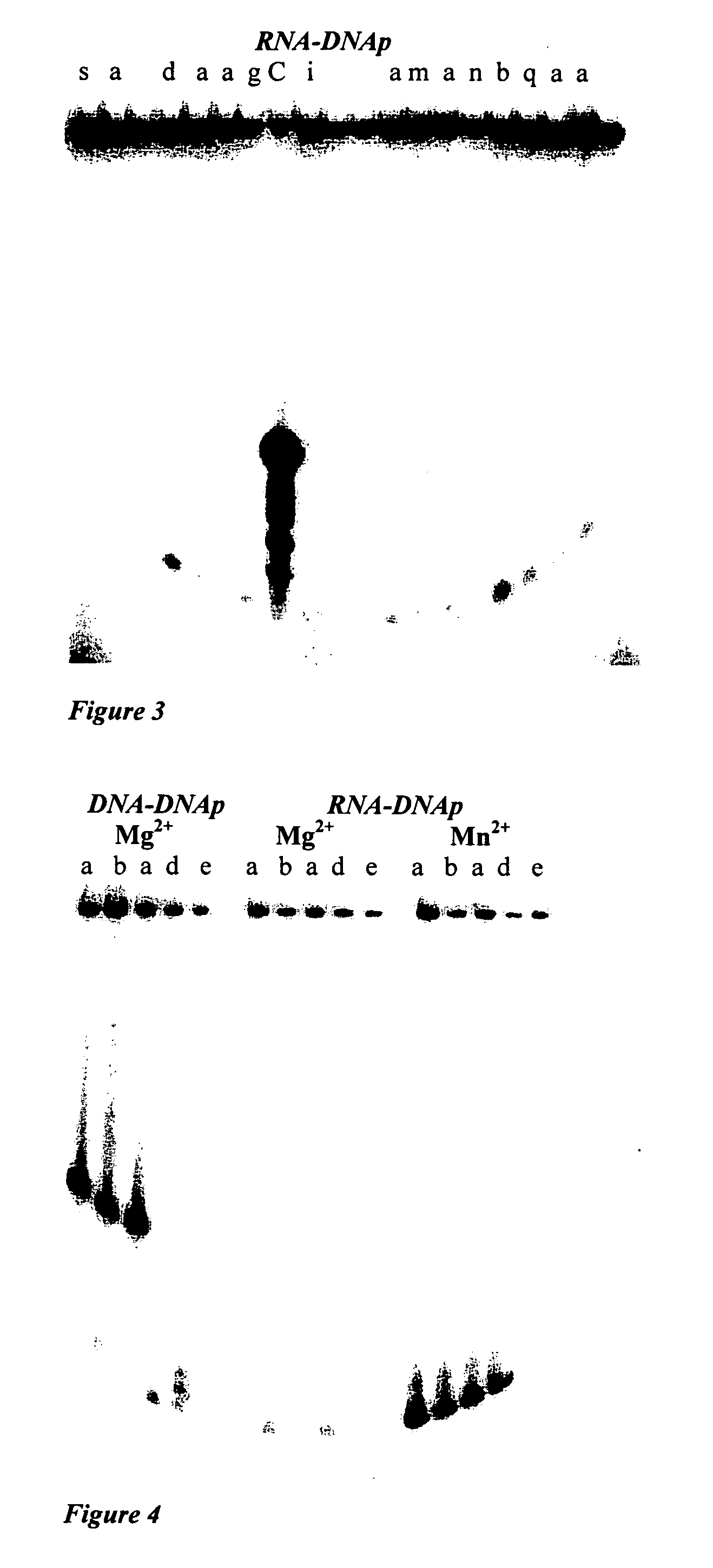

Polyclonal Phage-Polymerases (FIG. 2)

[0222] In this example, the reverse transcriptase activity of phage-polymerases was assessed as obtained after different rounds of selection in the presence of Mg2+ ions. In these experiments, a reverse transcription (RT) mix was used. The final concentration of each component in a reaction was: 10 μM RNA (SEQ ID NO: 12); 5 μM DNA (SEQ ID NO: 13); 0.25 mM dNTP; 3 mM MgCl2.

[0223] Each 1.2 μl aliquot of the reaction mix was further mixed with 15 μl of phage-polymerase polymerases (108 particles) after one round of selection round, either not preheated or heated 5 min at 65° C. before reaction of polymerization. The solutions were then incubated at 37° C. for 15 min. The reactions were stopped by adding 15 μl of the denaturation solution, heating for 3 min. at 94° C. and placing on ice.

[0224] The incorporation of alpha 32P-dTTP was determined on 20% polyacrylamide gel; 15 μl of the final reaction volume were loaded. The positive control was perfo...

example 3

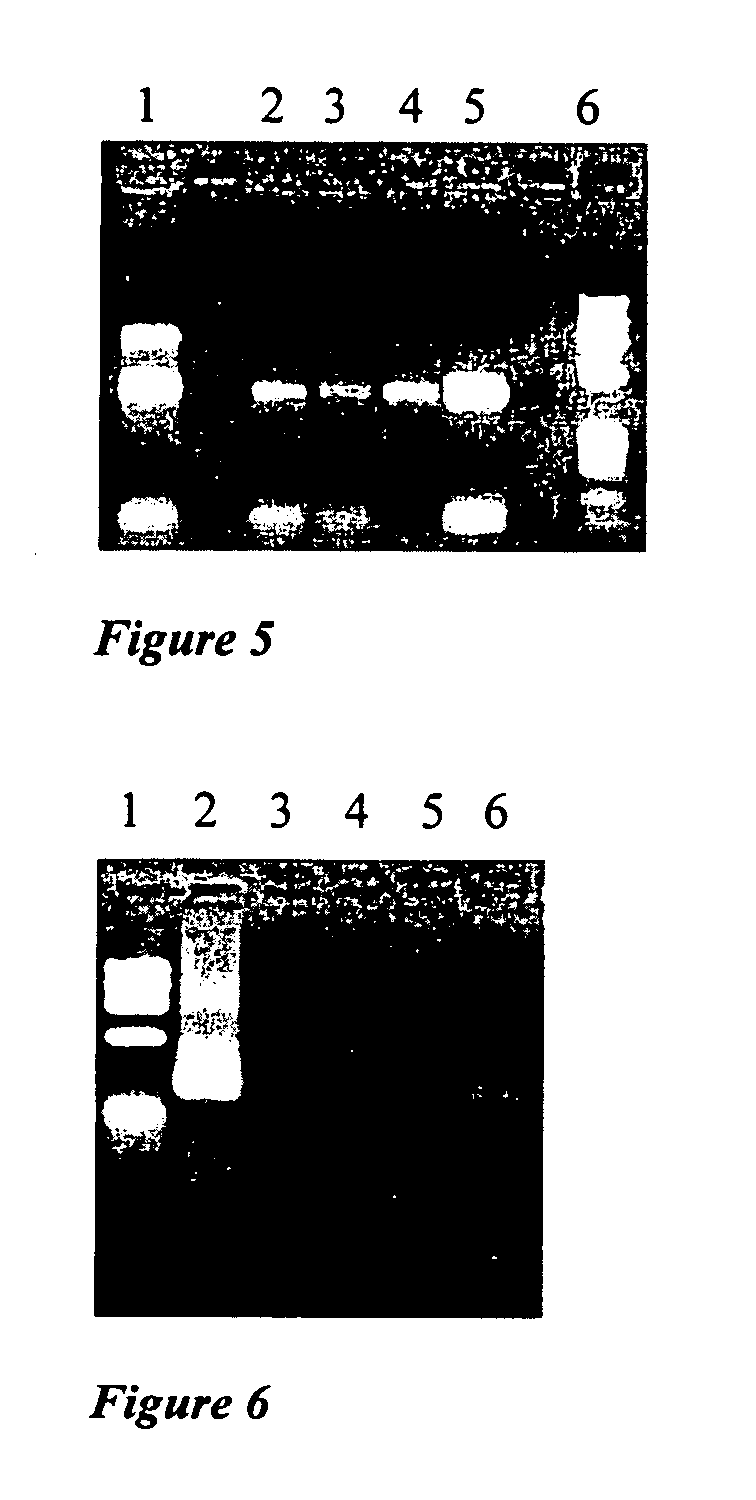

Monoclonal Phage-Polymerases (FIG. 3)

[0229] In this example, the reverse transcriptase activity of various monoclonal phage-polymerases obtained after round 6 in the presence of Mg2+ ions was assessed. In these experiments, a reverse transcription (RT) mix was prepared in which the final concentration of each component in a reaction was: 10μM RNA (SEQ ID NO: 12); 5 μM DNA (SEQ ID NO: 13); 0.25 mM dNTP; 3 mM MgCl2.

[0230] Each 1.45 μl aliquot of the reaction mix was further mixed with 15 μl of phage-polymerase heated for 5 min at 65° C. The solutions were then incubated at 37° C. for 20 min. The reactions were stopped by adding 15 μl of denaturation solution, heating for 3 min. at 94° C., and placed on ice.

[0231] The incorporation of alpha 32P-dTTP was determined on a 20% polyacrylamide gel; 15 μl of the final reaction volume were loaded. The positive control was performed using the AMV-RT (Promega), lane C.

[0232] The different monoclonal phage-polymerases were obtained among the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com