Plasma processing apparatus and method of designing the same

a technology of processing apparatus and plasma, which is applied in the direction of folding cycles, cycles, transportation and packaging, etc., can solve the problems of difficult to produce uniform microwave plasma, enlarge the processing time of substrates, and unsuitable cases, etc., and achieve the effect of convenient and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

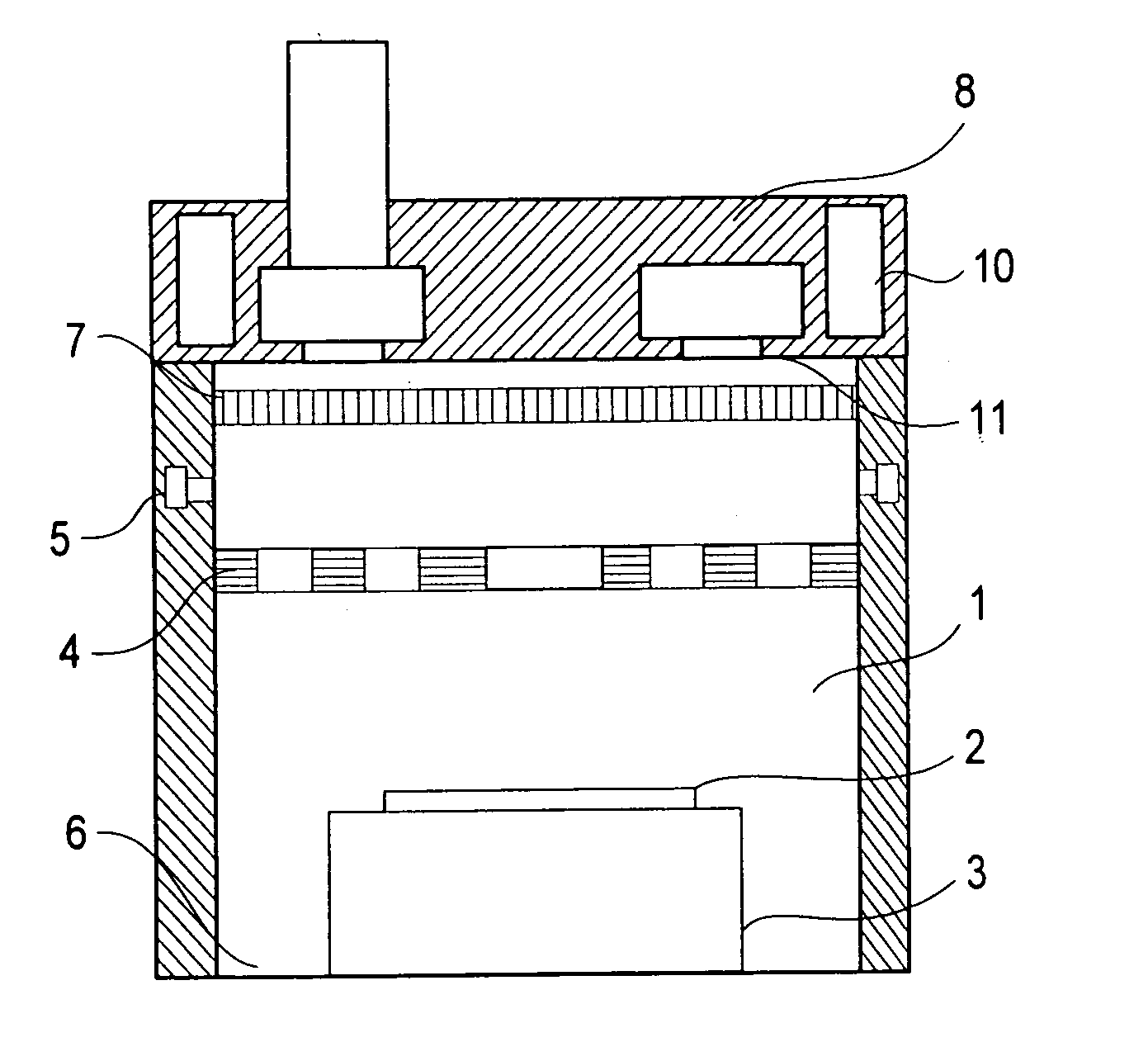

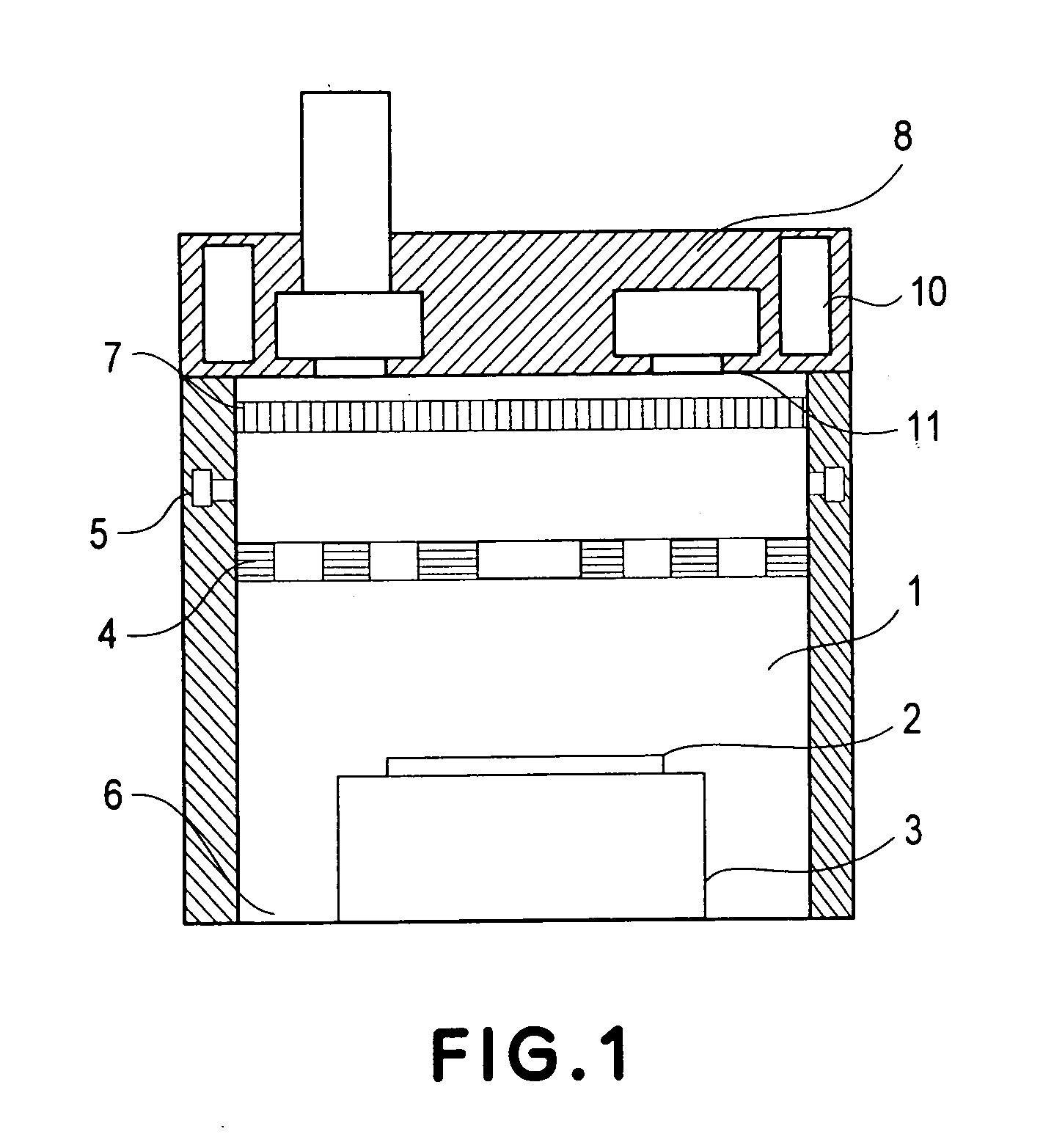

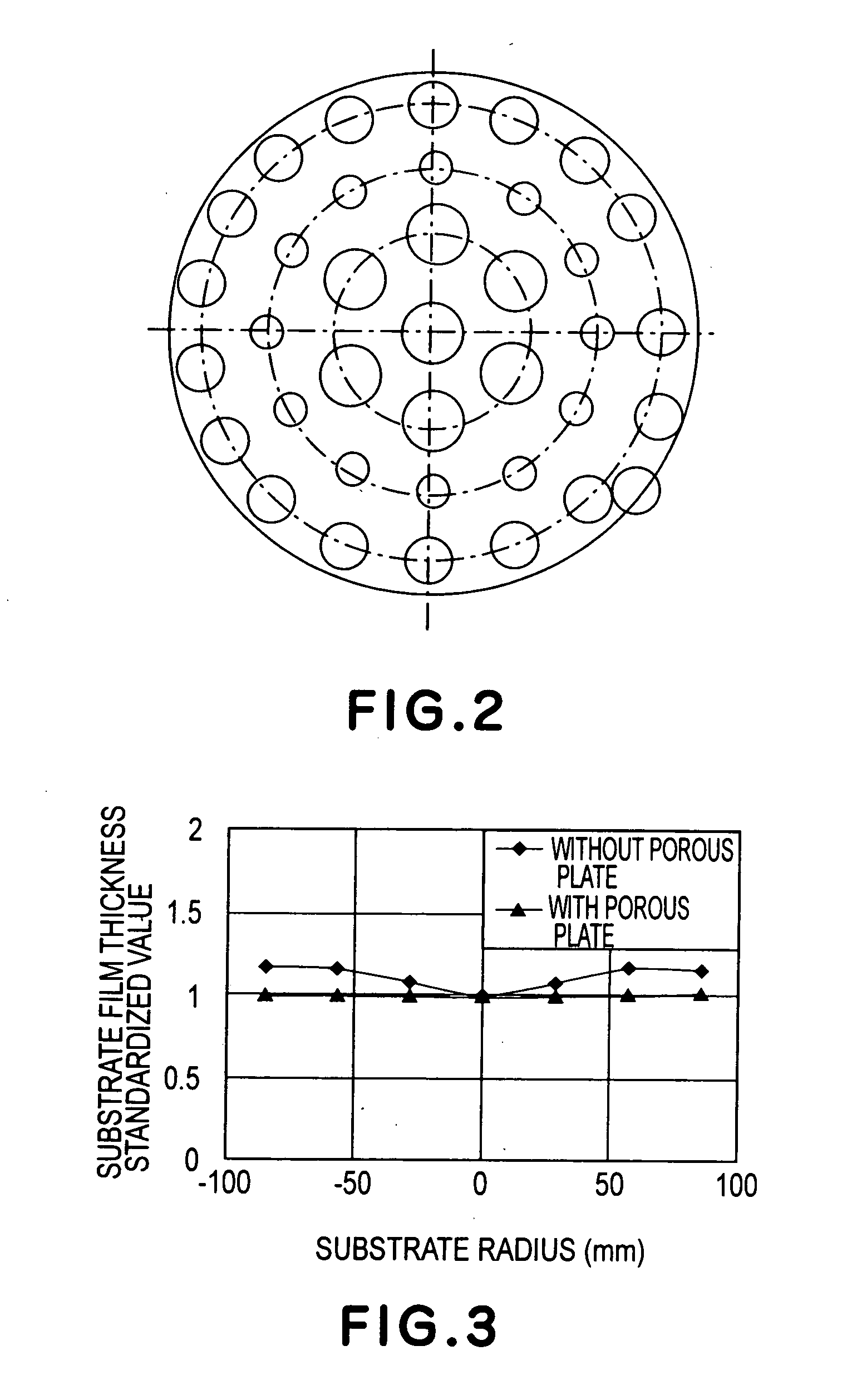

[0038] A first embodiment of the present invention will be explained in detail with reference to an example of microwave plasma processing apparatus shown in FIG. 1 of the drawings. In FIG. 1, denoted at 1 is a plasma processing chamber of cylindrical shape, and denoted at 2 is a substrate to be processed. Denoted at 3 is a substrate carrying table for carrying a substrate 2 thereon. Denoted at 4 is a porous plate, and denoted at 5 is a processing gas introducing means. Denoted at 6 is an exhaust port, and denoted at 8 is an endless circular waveguide with slots, for introducing microwaves into the plasma processing chamber 1. Denoted at 11 are slots which are formed in the circular waveguide 8 with a pitch corresponding to a half or quarter of the wavelength of the microwave inside the tube. Denoted at 7 is a dielectric material window for introducing microwaves into the plasma processing chamber, and denoted at 10 is a cooling water flowpassage formed in the waveguide 8. The inner...

embodiment 2

[0043] In this embodiment, the porous plate 4 of the microwave plasma processing apparatus according to the first embodiment was replaced by a porous plate having an opening ratio of about 0.1, and nitride processing was performed to a substrate 2 in a similar manner as the first embodiment. The sectional area of each hole of the porous plate 4 used in the second embodiment is a half of that of the porous plate used in the first embodiment. Thus, the hole diameter is 1 / {square root}2 (square root of 2), and approximately it is within the range of 7 to 15 mm. The disposition of holes of the porous plate 4 is similar to the first embodiment.

[0044] After completion of the nitride processing, the thickness increment of the silicon oxide nitride film at the substrate 2 surface, as converted in terms of silicon oxide film, was measured by use of an Ellipsometer (KLA-Tencor Corporation). The result was 1 nm±2%. Comparing the film thickness distribution on the substrate 2 after the nitride...

embodiment 3

[0046] In this embodiment, the porous plate 4 of the microwave plasma processing apparatus according to the first embodiment was replaced by a porous plate 4 shown in FIG. 5, and nitride processing was performed to a substrate 2 in a similar manner as the first embodiment. As regards the holes of the porous plate 4 used in the third embodiment, those holes placed along the first concentric circle, from the center, of the porous plate used in the first embodiment are removed while, on the other hand, the central hole is enlarged in size. Moreover, the opening ratio is made approximately equal to 0.22. Because the holes at the first concentric circle from the center are removed, a sufficient interval between adjacent holes can be assured even though the opening ratio is expanded to approx. 0.22. Hence, a sufficient mechanical strength of the porous plate is obtainable.

[0047] After completion of the nitride processing, the thickness increment of the silicon oxide nitride film at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| hole diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com