The ability to bulk purchase and

handle materials at a fixed manufacturing location also produces major cost efficiencies.

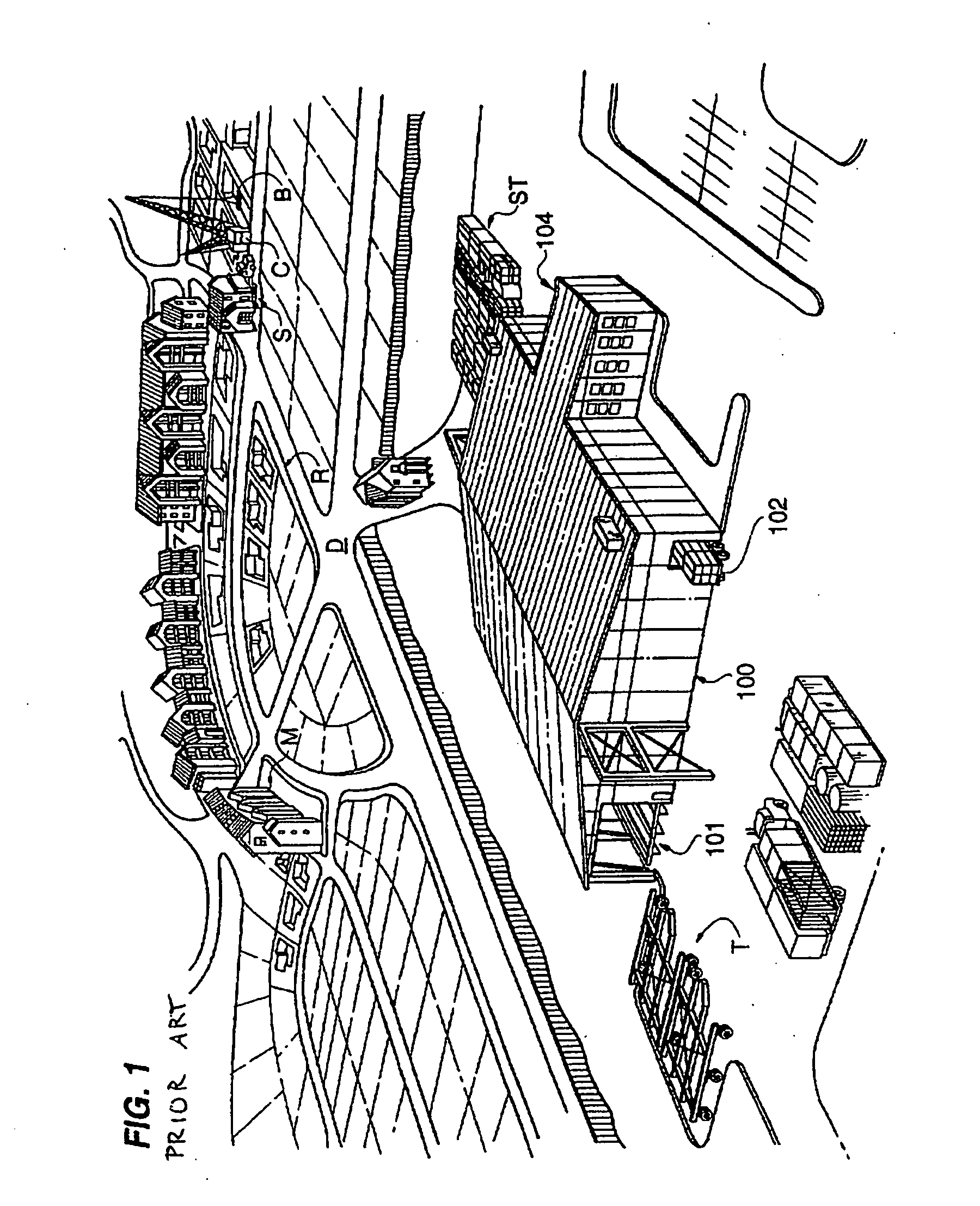

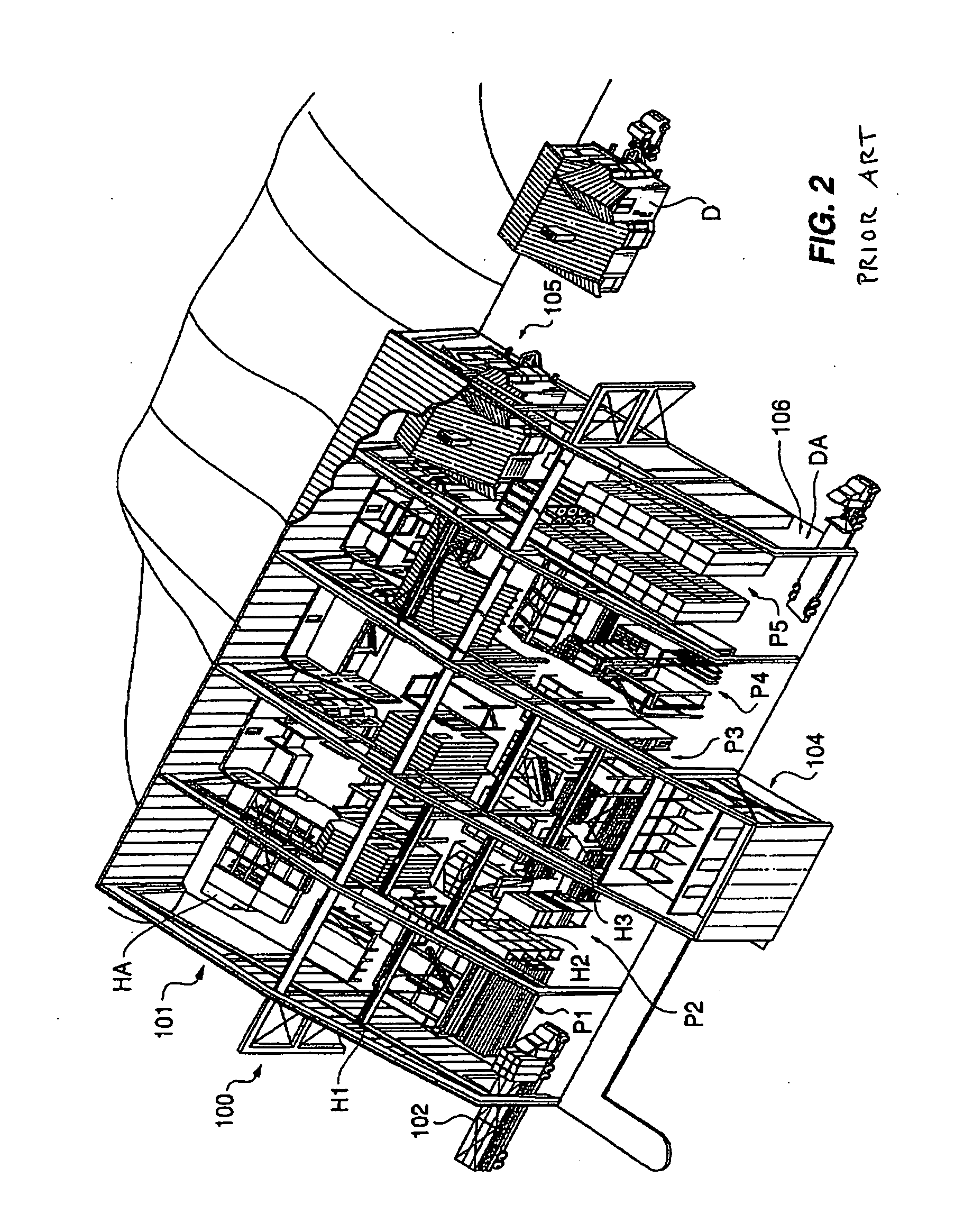

With panelized construction, major components of homes are either prefabricated in a remote factory environment or at the site where, unfortunately, panel installation is exposed to local weather conditions.

While this method of residential home construction has worked for many years, there are inherent inefficiencies in this method that result in significant cost penalties to the homebuyer.

These disadvantages form the core problems which face the housing industry today and, in particular, for the manufactured method: Dimensional and design constraints have confined manufactured homes to a limited market segment.

The manufactured method cannot be used to build standard size homes without segmentation of the home into modules of relatively small dimensions which results in design and

floor plan compromises.

Manufactured home segments are subject to significant architectural and

floor plan constraints because of the need to transport the completed modules over public highways and roadways.

There are significant size limitations in manufactured homes: typically single-story, 10-14 ft. wide by 50-70 ft. long with box-like architecture.

The cost of shipping modules from the factory to the destination, placing the modules on to the foundation, field

mating the modules together on non-repetitive site conditions in sites often 50 miles from each other, distributing manufactured homes through expensive dealer merchandising organizations, installing final finishes on individual homes with 10% of the work being applied at the remote site, and providing support service over a wide

geographic area all aggregate to a significant

cost component in these products.

There is a possibility for damage to manufactured home modules during extended transport over the public

highway system.

Manufactured home factories are operationally constrained from serving the stick-built new

community home market because these communities often require significant production rates of 4 to 15 homes per month over 2 to 5 years, which would displace production available to the dealer network serving the factory resulting in unacceptable

distribution system disruptions.

There are also problems with panelized constructed homes: Field labor is required for field

assembly of panels.

Less than complete dwelling units are produced, since it is a method to produce only segments of homes, which thereby limits the incremental

manufacturing efficiency to only that small portion of the home that is actually constructed in the factory.

The panelized method of construction cannot build standard size homes without segmentation of the home into modules of relatively small dimensions which results in many compromises.

Therefore, finish work remains a subcontractor activity in the field of panelized construction, thereby limiting the

cost savings that can be realized by the panelized construction builder with regard to the comparable cost of a stick-built home.

The panels or components that are manufactured require major field

assembly which takes a significant amount of time and are therefore exposed to local weather conditions.

The panels built in a remote

plant have size limitations because of the necessity to transport these panels over public highways and roadways.

The panelized method of construction only accelerates the framing segment of the construction, which represents only an incremental time savings on what presently is a several week portion of a 3 to 8 month project.

There is a possibility for damage to panels and components during extended transport and handling.

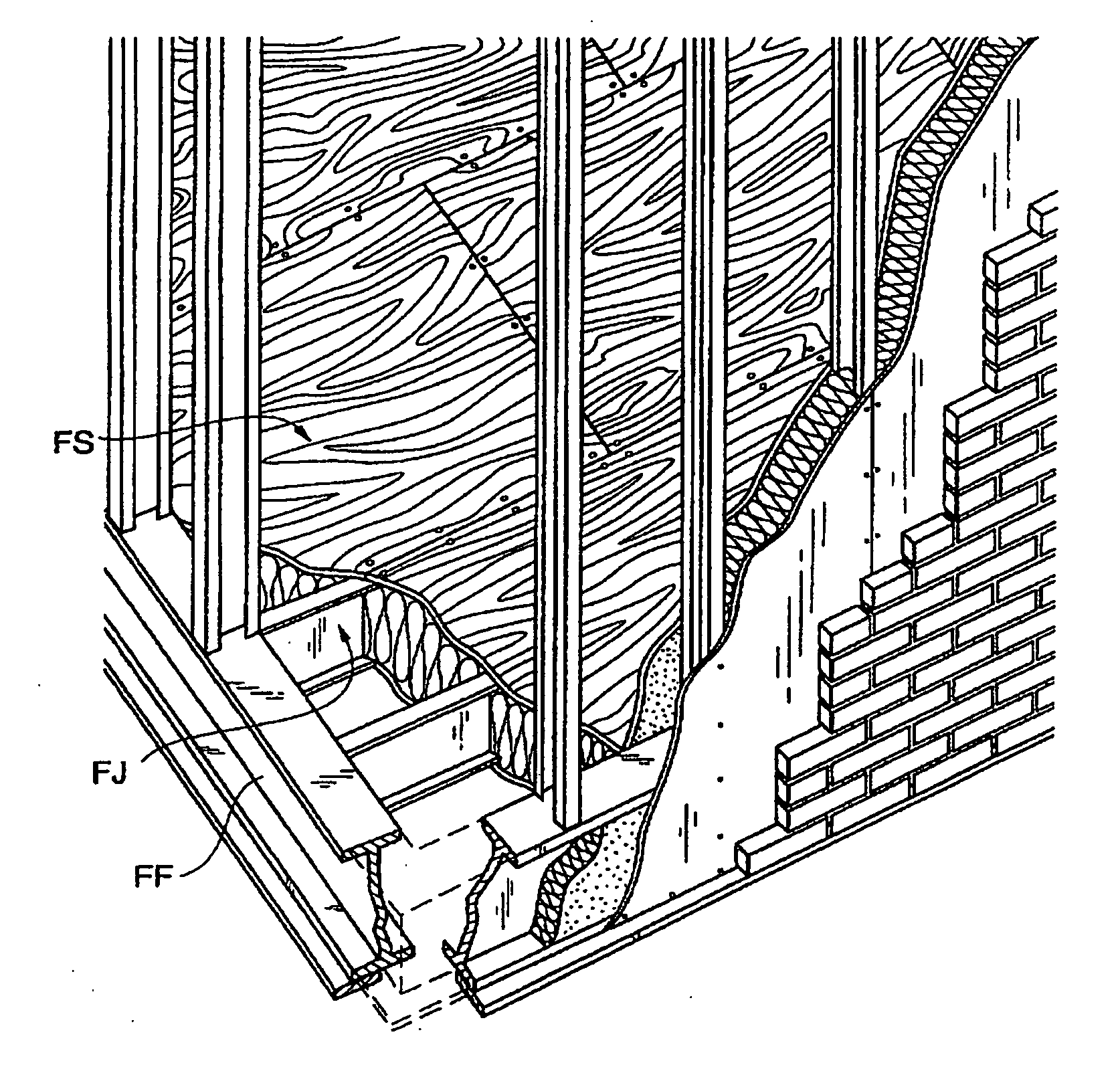

There are also problems in the stick-built method of dwelling construction: Stick-built construction is inherently a sequential home

building process—floor are built before walls, walls before ceilings, and the roof after all the other framing is completed.

This is a lengthy process and therefore results in construction activity of extended duration.

Much of the work done in stick-building a dwelling is at the mercy of local weather conditions which can

delay schedules and cause water-related damage to materials, including mold damage.

Bulk material delivery and handling are not possible because the materials need to be segregated for each individual home.

It is common to have 3 to 8 month construction schedules in stick-built construction of a dwelling, which result in the additional cost of capital and financing for this period of time.

The cost of labor in stick-building is high to thereby attract the necessary skill levels to widely scattered job sites.

In addition, there is a hidden cost of the workers having to travel to various and changing job sites for short durations, with the field handling of materials representing another inefficiency and a source of additional defects, which must be corrected at an additional cost.

A significant

disadvantage of the stick-built dwelling construction technique is that, regardless of the size and / or complexity of the dwelling, these homes are built according to a process that is determined by both building codes and the need for efficiency of the various independent subcontractors that are engaged to construct the dwelling.

Therefore, while each individual subcontractor task does not necessarily take a lot of time in constructing a stick-built residential dwelling, the time intervals between the arrival of the various subcontractors and delays occasioned by weather and other subcontractor work significantly lengthens the amount of time required to complete each dwelling.

Furthermore, operating in a field environment is detrimental to maintaining the quality of the construction since it is difficult using portable hand tools to precisely

cut and assemble framing material into walls and various finish elements with precise tolerances.

It is often difficult in stick-built home construction to find a sufficient number of skilled workmen who can craft a residential structure of high quality at very reasonable costs.

The quality suffers and there is also a significant amount of waste, since the materials must be handled at least 2 to 3 times between shipment from the factory or mill to being delivered to the individual job site.

There is excess labor and significant breakage as a result of this repetitive handling of materials.

In addition, typically there aren't people at individual job sites all day to receive materials, so materials and supplies are exposed to the possibility of delivery damage, theft, and

bad weather.

Surplus materials, unless they represent a significant quantity, are discarded since the value of salvaged materials does not offset the cost involved to salvage these materials.

While the stick-built residential structure is the most desirable

residence for consumers because of the design flexibility, the cost benefits obtained by the factory manufacturing environment are unavailable to this type of construction method due to the size and more often than not multi-story nature of these structures.

Login to View More

Login to View More  Login to View More

Login to View More