Rate-controlled freezer and cooling methods thereof

a temperature control and freezer technology, applied in the field of cooling devices, can solve the problems of inability to uniformly cool samples within the device, inability to accept and irreversible damage to cells, and inability to control the temperature of the sample, so as to reduce the temperature differential, increase the total sample volume or sample, and reduce the effect of temperature differential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 4

[0122] Evaluation of Cryomed Freezer to Provide Rate-Controlled Cooling Comparative Example 2 was repeated with the exception that the sample trays were filled with ampoules as shown in FIG. 6 having alternate or every-other main openings filled with an ampoule and all minor openings vacant for a total of 45 openings per tray filled with ampoules of the 162 available openings, such that no filled opening, that is an ampoule occupied opening, has a nearest-neighbor opening that is filled or occupied with an ampoule. A cooling rate of about −1° C. per minute produced nearly uniform cooling and freezing results.

example 5

[0123] Evaluation of Kryosave Freezer to Provide Rate-Controlled Cooling Example 4 was repeated with the exception that the freezer was a Kryosave 750-30 having a laminar flow pattern characteristic. A cooling-rate program was used which automatically compensates for the total number of sample ampoules in the chamber and their collective impact on the total heat of fusion sample load. A cooling rate of about −1° C. per minute produced nearly uniform cooling and freezing results.

example 6

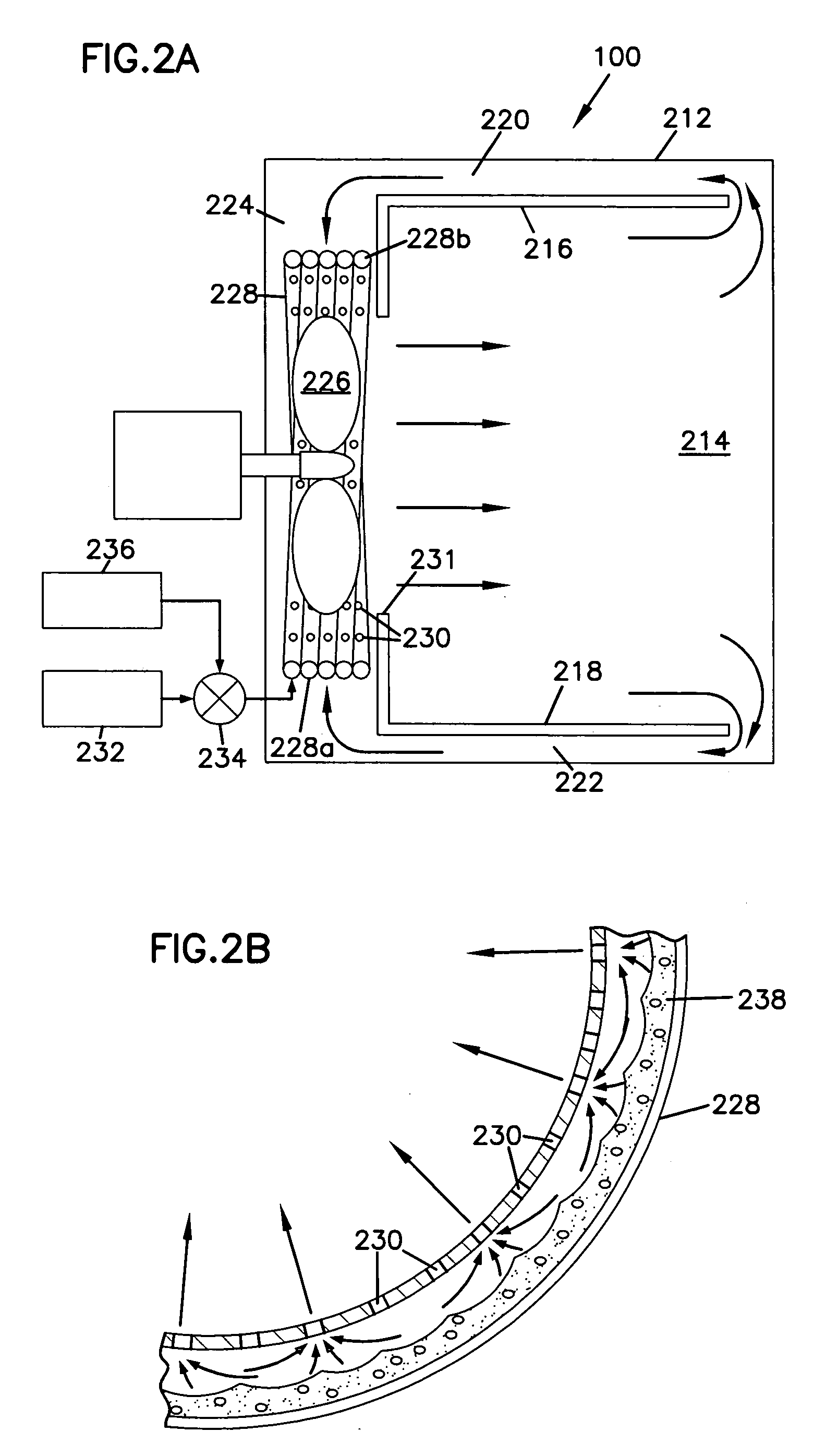

[0124] Evaluation of ThermoForma Freezer to Provide Rate-Controlled Cooling Example 4 was repeated with the exception that the sample trays had a slightly different configuration and capacity. The trays were filled with ampoules as shown in FIG. 7 and a ThermoForma Model 7454 freezer, see the abovementioned U.S. Pat. No. 6,044,648, was used having a larger fan, a higher capacity fan motor capable of providing greater convection, a larger chamber, a heat transfer coil based on liquid nitrogen “spray,” and capable of accomplishing the following instruction “hold chamber at temperature X until sample temperature is Y”.

[0125] In preliminary experimental trials with this freezer in several configurations, such as using one, two, or three trays, it was apparent from the sample temperature data and the cooling-rate measurements that the cooling pattern within in the chamber can be markedly affected by the rack and tray configuration. This observation prompted further modification of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com