Process for manufacturing low nicotine tabacco leaf substitute

a technology of tobacco leaf substitute and pretreatment process, which is applied in the fields of tobacco treatment, tobacco manufacture, tobacco manufacturing, etc., can solve the problems that no prior art illustrates the drying of natural plant leaves, and achieve the effects of reducing the risk of cancer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

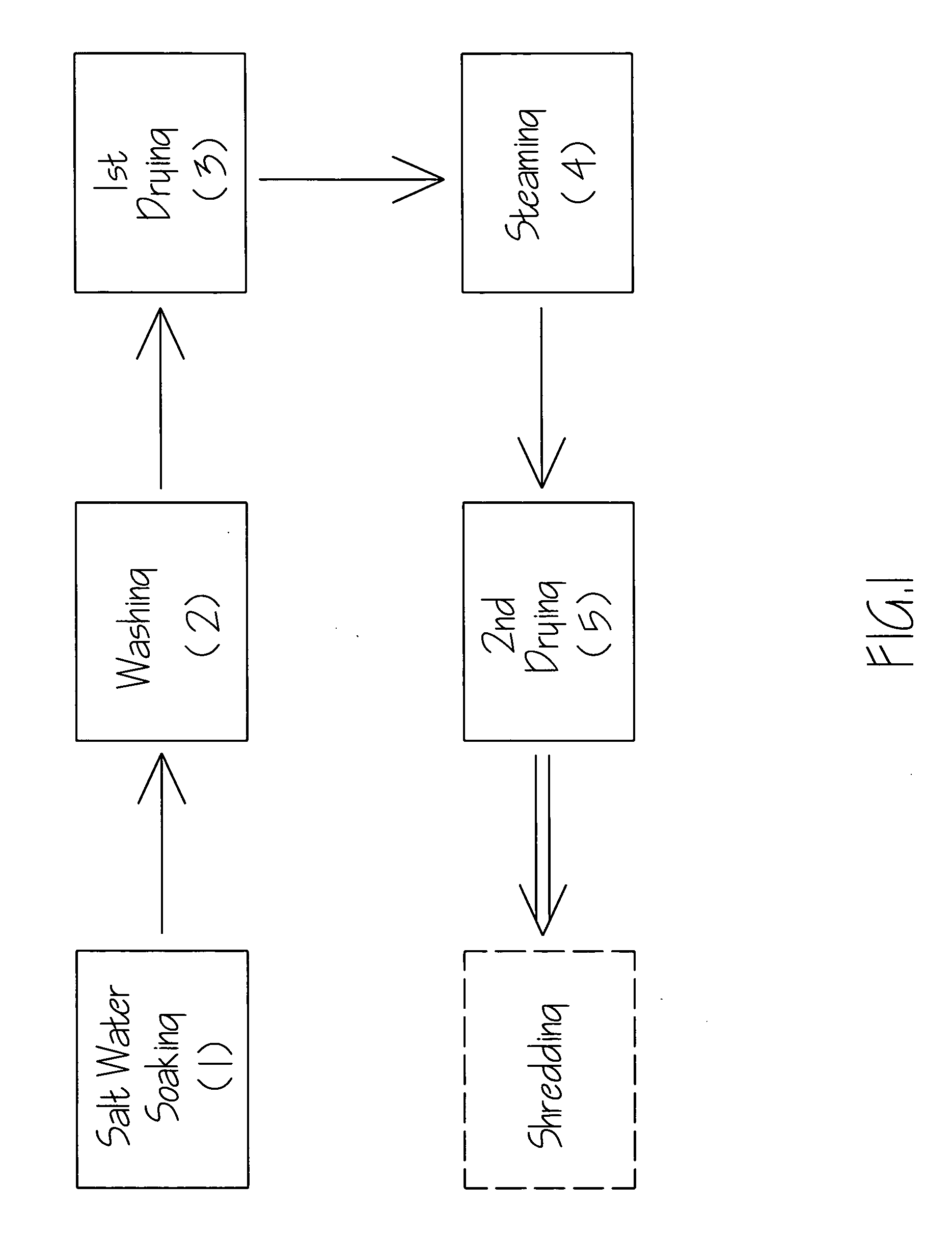

[0014] As shown in the FIG. 1, the schematic drawing of the procedure, the pre-treatment procedure of this invention consists of: 1) a salted water soaking; 2) washing; 3) 1st drying; 4) steaming; and 5) 2nd drying.

[0015] In step 1), leaves of the Morus alba L. and Lillium longiflorum gathered from the mountain regions of Korea and China are soaked with salted water at ambient temperature to eliminate dirt on the surface. 600 grams of rock salt is dissolved in 2.5 gallons of distilled water. The temperature of the water is maintained between 10 to 30 degrees Celsius. Soak the leaves in the salted water for one week.

[0016] In step 2), wash the leaves with distilled water for 24 hours.

[0017] In step 3) washed leaves are dried at a temperature between 20 and 45 degrees Celsius in the open air.

[0018] Step 4) is steaming. 600 gram of the 1:2 mixture of the leaves from the step 3) are put into a batch steamer of commercial steam cooker containing 1 gallon of a distilled water there un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com