Heat-pipe engine structure

a technology of engine structure and heat pipe, which is applied in the direction of indirect heat exchangers, heat exchange apparatus, lighting and heating apparatus, etc., can solve the problems of limiting the application of evaporator and condenser, affecting the horizontal flow of fluid, and unable to truly effectively conduct the fluid between two phases, etc., to achieve better heat conduction effect, flat structure, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

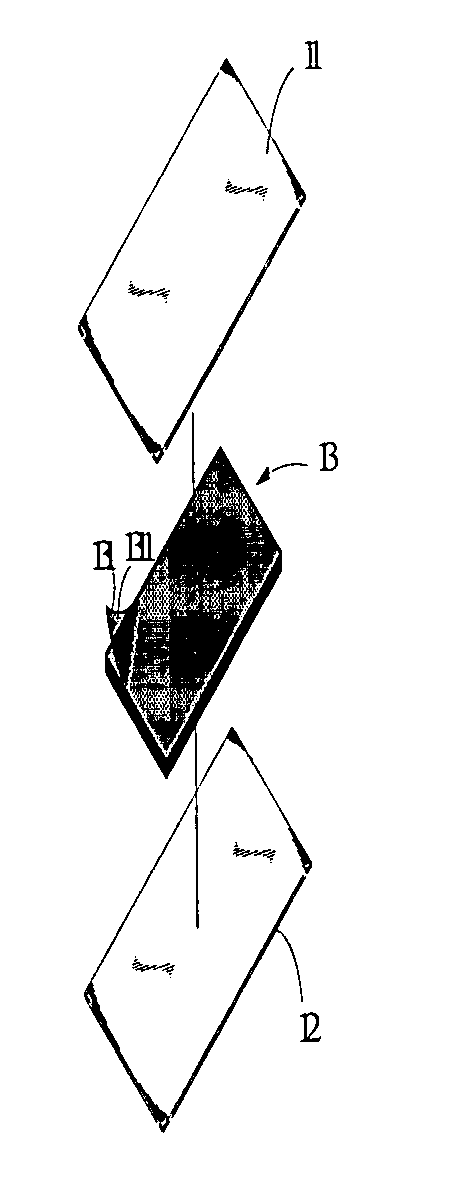

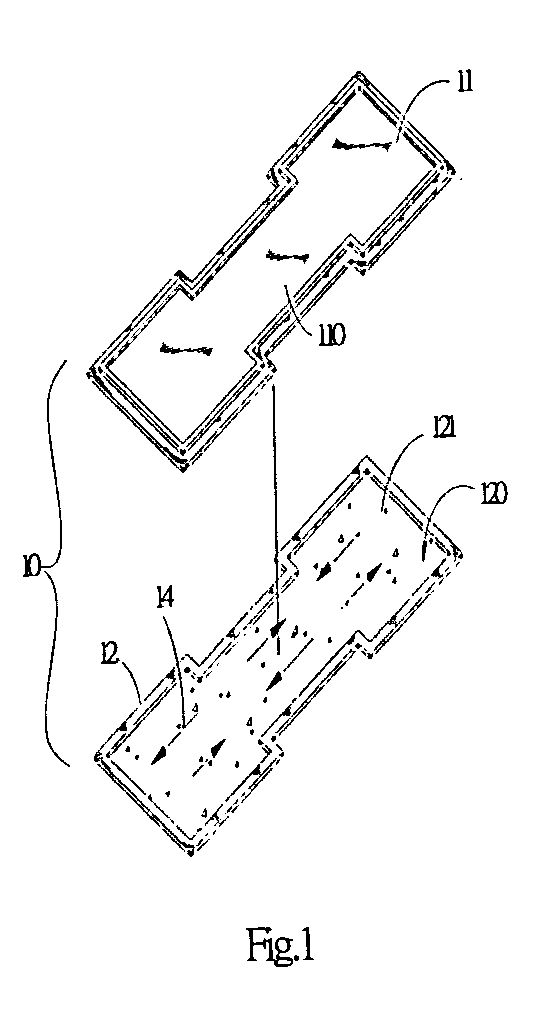

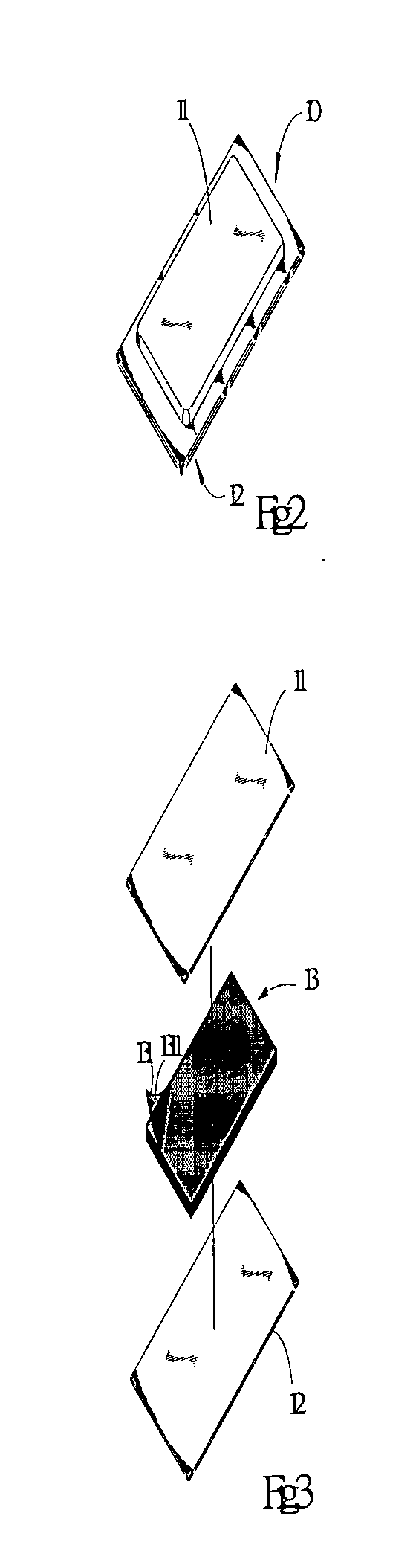

[0032] Please refer to FIGS. 2, 3 and 4. The heat-pipe engine of the present invention includes a housing 10, a metal mesh laminate 13, a fluid 14 and a vapor chamber 15A.

[0033] The metal mesh laminate 13 is formed of one single metal mesh folded into multiple layers. Alternatively, the metal mesh laminate 13 can be composed of more than two metal meshes 131 which are tightly laminated with each other. The metal mesh 131 is formed of metal wires which longitudinally and transversely intersect each other to evenly form numerous meshes. After the metal meshes are laminated, more or several times meshes will be formed between the laminated metal meshes.

[0034] The housing 10 is composed of an upper metal film 11 and a lower metal film 12. The peripheries of the upper and lower metal films 11, 12 are connected and sealed. The upper and lower metal films 11, 12 are respectively bonded to and connected with upper and lower faces of the metal mesh laminate 13. After the peripheries of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com