Method for producing a stratified composite material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

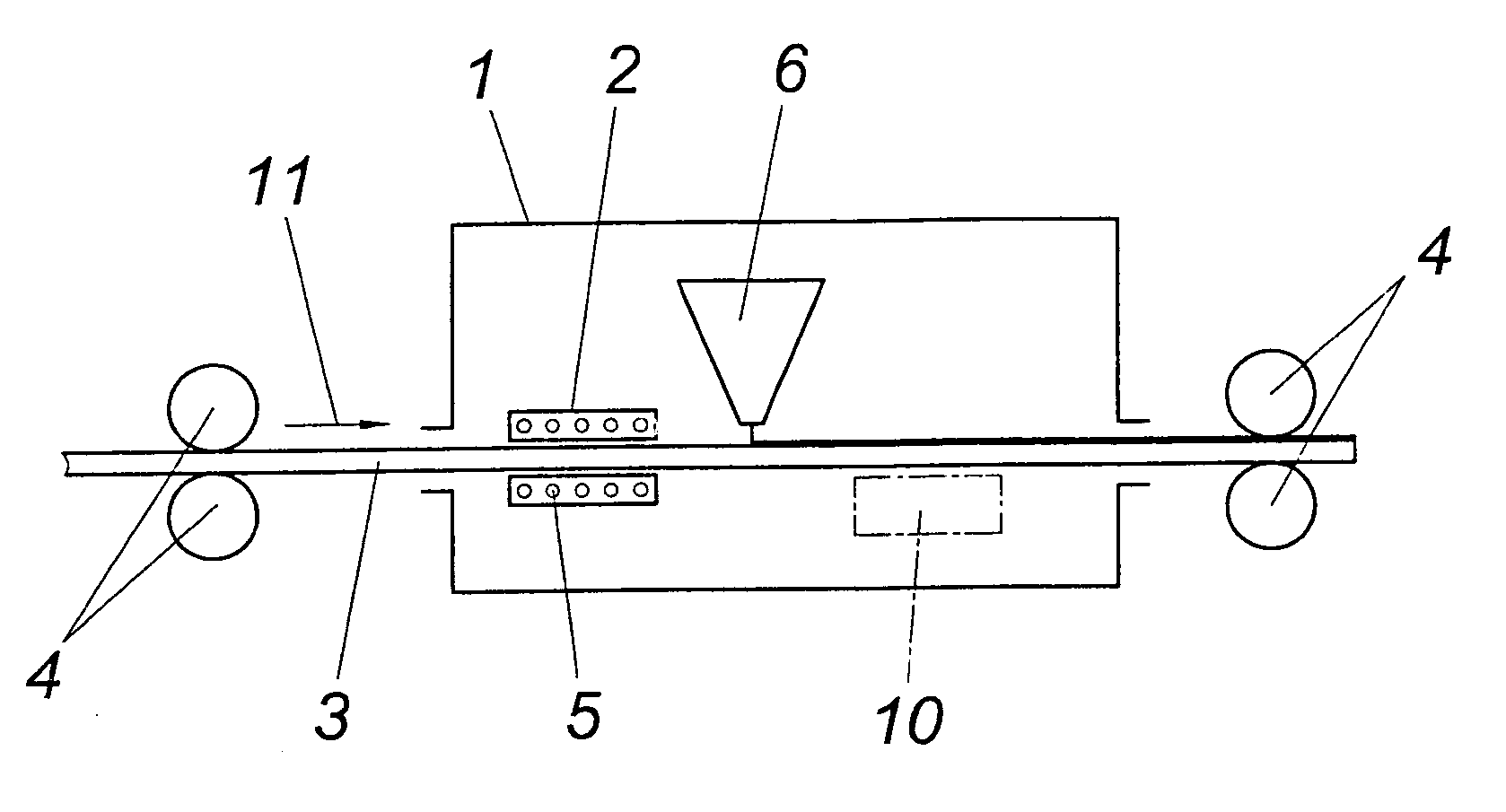

[0013] According to the embodiment according to FIG. 1, a device 2 for the inductive heating of a strip-like metal carrier 3 is provided within a protective hood 1 for maintaining an atmosphere of inert gas, which carrier is conveyed with the help of driving rollers 4 through the protective hood 1 and is heated on passing through the windings 5 of at least one inductive coil before solids particles (e.g. a sintering powder) is applied onto the metal carrier 3 for the applied layer material with the help of a scattering device 6.

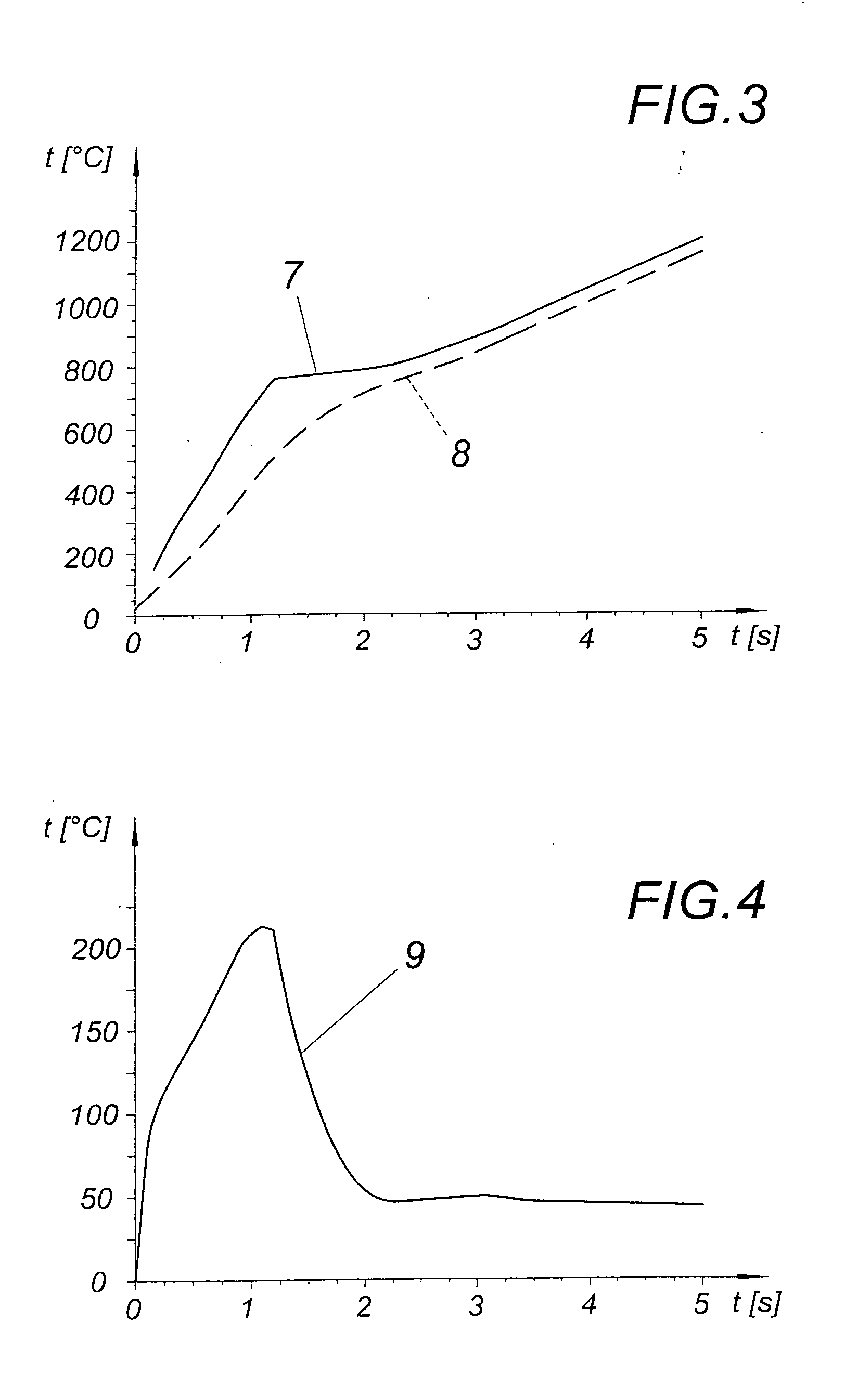

[0014]FIG. 3 shows the heating curve over time for a steel metal carrier 3 with a thickness of 5 mm shown on the one hand in a surface layer and on the other hand in a core layer. The curve 7 of the surface temperature as shown with the unbroken line leads to the consequence that at a suitable field frequency of 200 kHz for example the surface temperature of the metal carrier 3 rises only gradually again after exceeding the Curie point. However, in the case ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com