Reaction apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

production example 1

Production of a Film-formed Catalyst

[0051] A film-formed catalyst made of a three-component copper-nickel-ruthenium catalyst active material and carried on synthetic zeolite was prepared as follows.

[0052] Synthetic zeolite was charged into a flask having a volume of 1 L, and subsequently thereinto was put a solution wherein copper nitrate, nickel nitrate and ruthenium chloride were dissolved in water in such a manner that the ratio by mole between the metal atoms therein would satisfy: Cu:Ni:Ru=4:1:0.01. While the solution was stirred, the temperature thereof was raised. An aqueous 10% by weight Na2Co3 solution was dropwise added slowly at 90° C. to the solution while the pH thereof was controlled into the range of 9 to 10. The solution was ripened for 1 hour, and subsequently the resultant precipitation was filtrated, washed with water, dried at 80° C. for 10 hours, and then calcined at 600° C. for 3 hours to yield a powdery catalyst active material. The ratio of metal oxides in ...

example 1

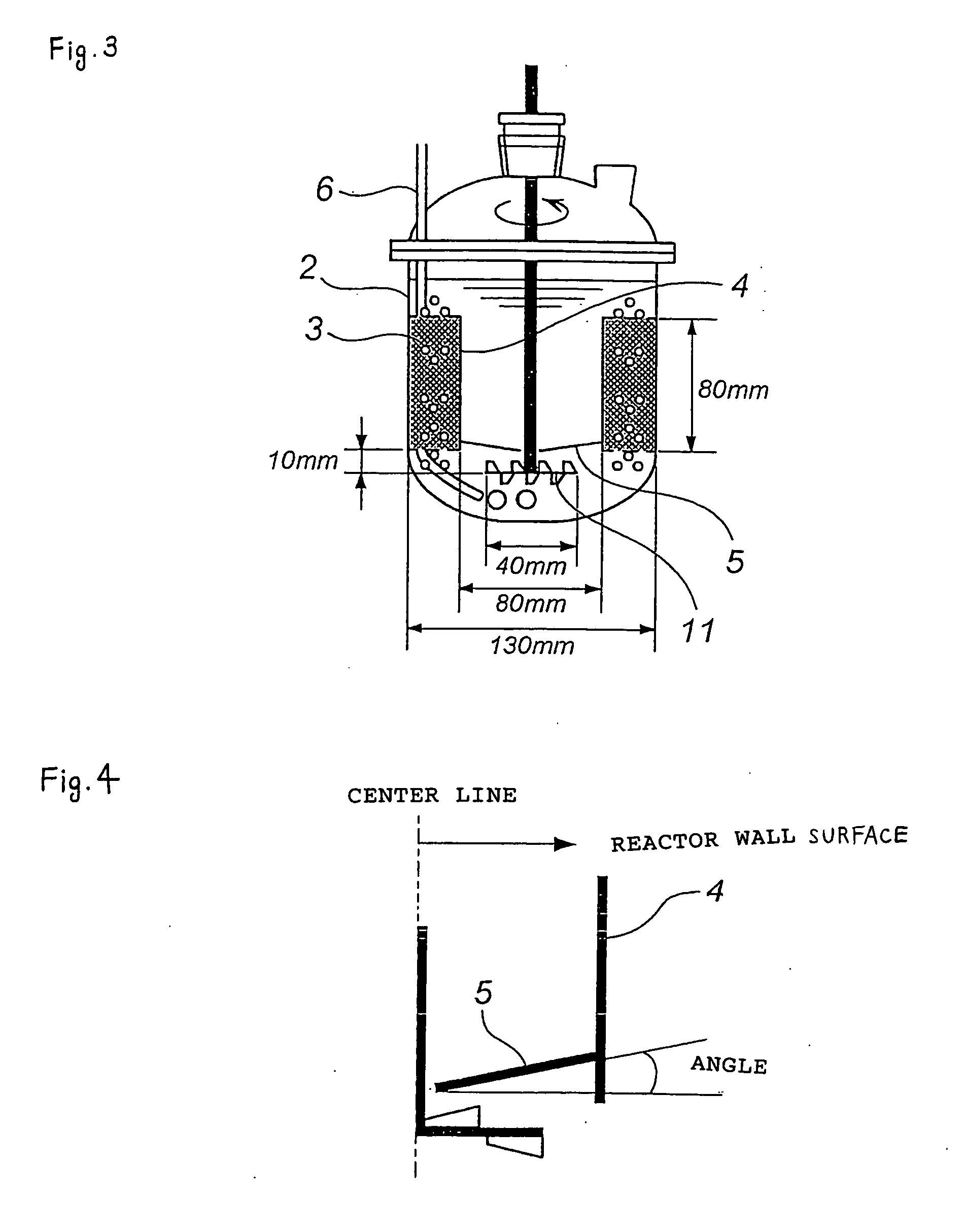

[0054] The reaction apparatus illustrated in FIG. 3 was used to conduct the following reaction.

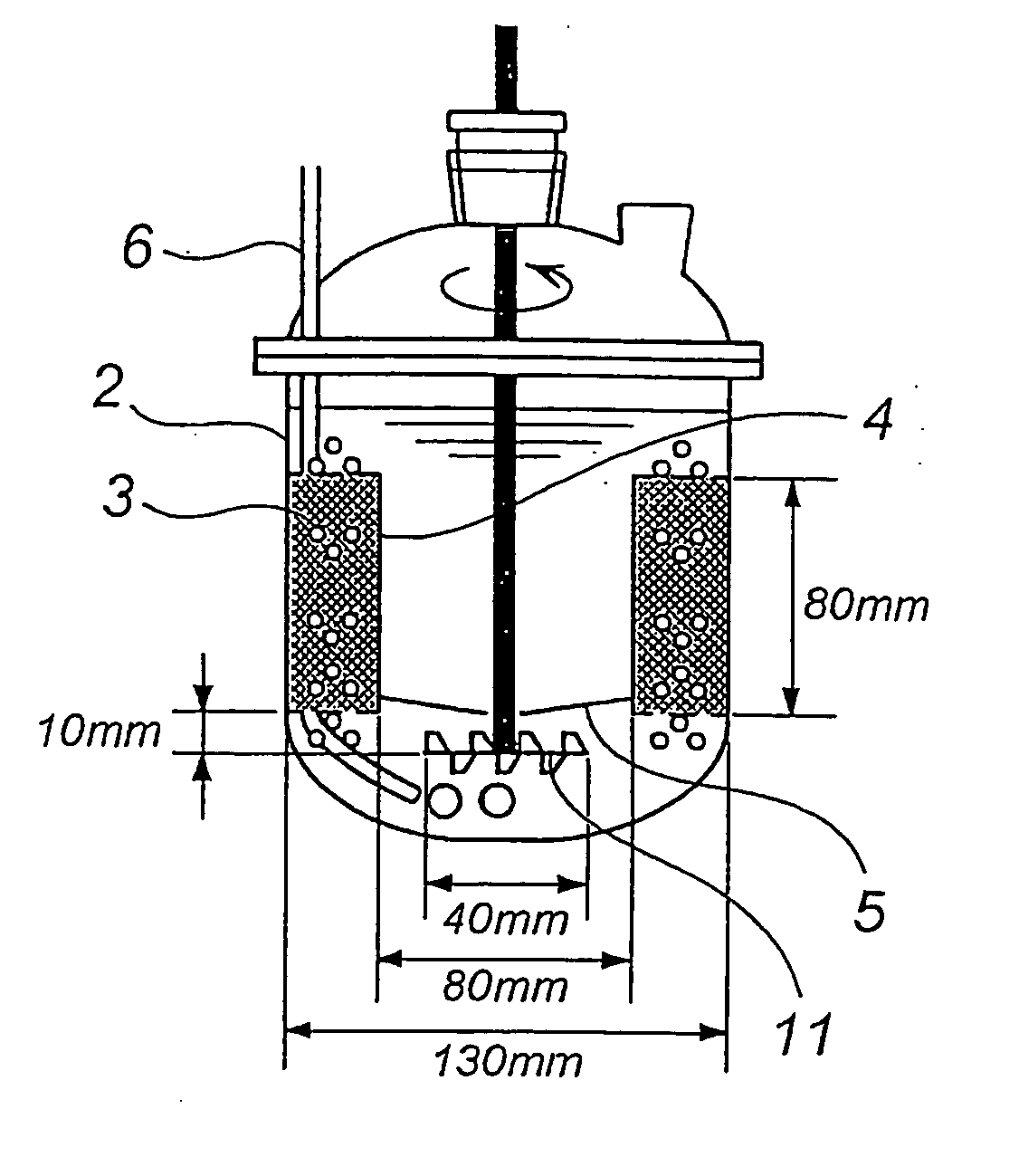

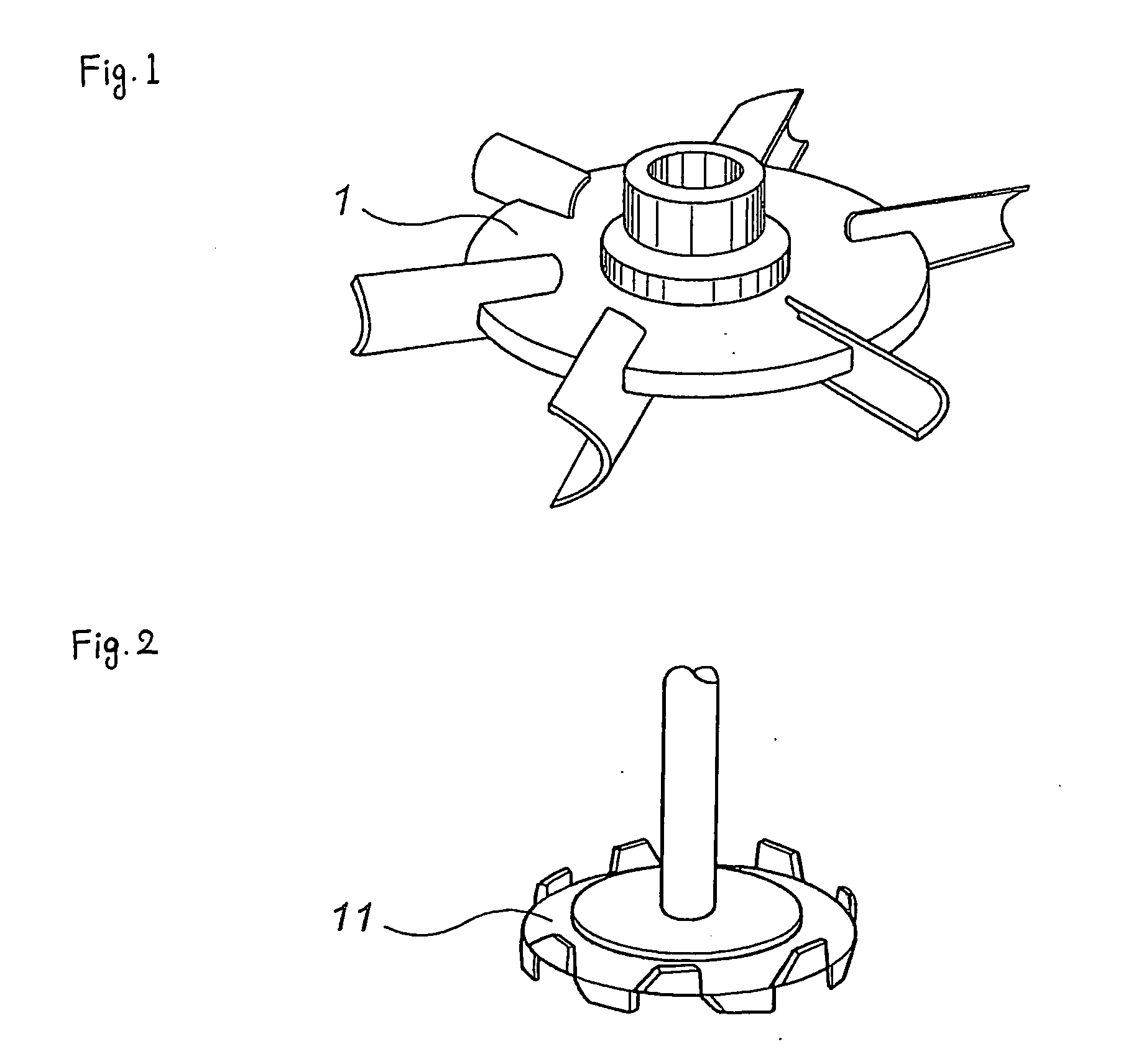

[0055] A part of the film-formed catalyst obtained in Production Example 1 were folded into waved plates, and the wave plates and the remaining flat plates were alternately wounded in layers and arranged into the form of a doughnut having an inside diameter of 80 mm and an outside diameter equal to the inside diameter (inside diameter: 130 mm) of the 2-L separable flask 2 made of glass. The volume of the region 3 into which the film-formed catalyst was fitted was 660 mL. The film-formed catalyst was thus formed to have plural channels being continuous through the axial direction of the separable flask 2. Each channel had a cross-section area of about 0.1 cm2. Into the separable flask 2 was charged 1200 g of dodecyl alcohol (Kalcol-2098, manufactured by Kao Corp.), and then hydrogen gas was blown in at a rate of 20 L / h, the rate being calculated in terms of the standard state volume thereo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com