[0008] The present invention involves stabilizing a surface against wind

erosion and controlling windblown particles in an effective and relatively inexpensive way by the use of a porous tubular windblown

particle control device and a method which makes use of such a porous tubular control device. The porous tubular control device may be constructed relatively quickly and inexpensively from common materials by bringing the construction materials to the site where the control devices are to be used, or by preassembling the control devices and transporting them to the site where they will be used. The porous tubular control device assumes a shape and color which blends with the natural

habitat in which it is used. The structure of the porous tubular control device facilitates its disassembly for removal during those seasons of the year when it is not needed, or facilitates its transportation and storage in an assembled state so that it can be easily deployed when needed again. The structure of the porous tubular control devices makes it easy to move them to achieve the best windblown

particle control effect. The porous tubular control devices are constructed of materials which do not present a significant collision

hazard from errant vehicles which leave a roadway, but instead attenuate or diminish the velocity of the errant vehicles and thereby reduce the risk of damage to the vehicle and its occupants. Significantly, however, the porous tubular control devices are very effective in stabilizing a surface against wind erosion and depositing and retaining windblown particles carried by wind blowing from a relatively wide range of

wind direction angles. The relatively inexpensive and effective nature of the porous tubular control devices facilitate their use in many other applications, such as protecting

topsoil from wind erosion, and facilitating the

revegetation of disturbed areas by increasing soil

moisture and protecting

plant growth from wind, sun and animal

grazing.

[0009] The porous tubular control devices of the present invention may also be used to make

beneficial use of a discovery that maintaining and stabilizing the snowcover adjacent to a roadway is essential in avoiding dangerous roadway

icing conditions. The most prevalent prior use of snow control devices has been to deposit snow away from the roadway to prevent accumulations on the roadway itself. Not fully recognized or utilized for purposes of roadway safety is the discovery that snow which continually sifts across the roadway is a significant cause of roadway

icing. The roadway absorbs

solar energy and is usually warmer than the surrounding air during

daylight hours.

Blowing snow coming in contact with the pavement melts, forming a layer of water and extracting heat in the process. With the wind continually sifting snow over the roadway, the

thermal energy is removed from the roadway pavement by melting the snow faster than

solar energy is absorbed by the roadway, thereby causing the layer of

liquid water to refreeze into a

thin layer of ice over the roadway. The implication of the discovery that continually sifting snow is a major cause of roadway icing, is that the snow control devices must not only prevent the accumulation of snow on the roadway, but should also stabilize the roadside snowcover to prevent the snow from continually sifting over the roadway even in amounts which would not otherwise impede traffic.

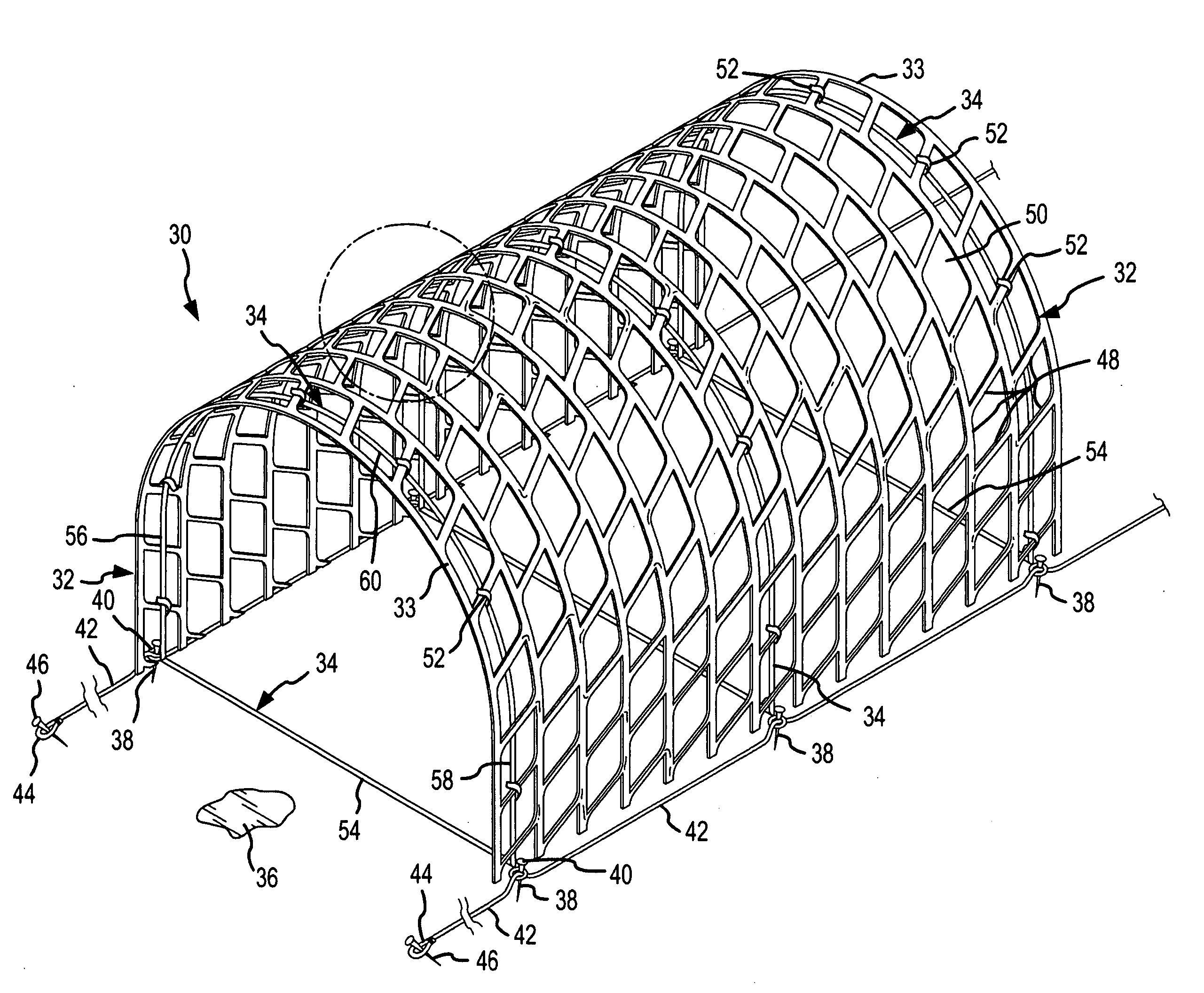

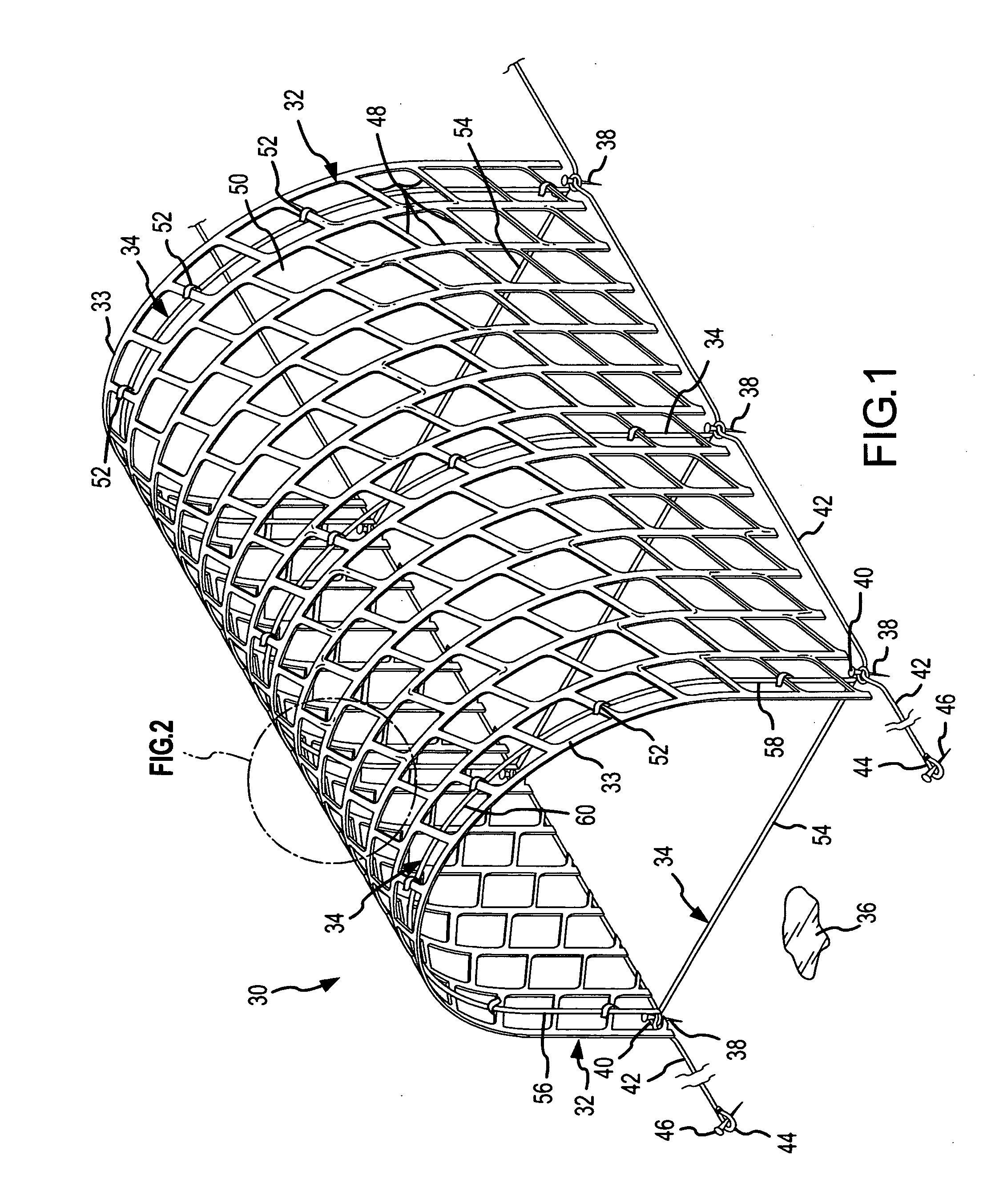

[0010] In accordance with these and other considerations, the present invention is directed to a tubular porous windblown

particle control device and method for controlling the deposition and retention of windblown particles, such as snow. The porous tubular windblown particle control device comprises a plurality of longitudinally separated frame structures defining an outer

peripheral shape and arranged horizontally in series, and a sheet of netting material having a plurality of interconnected webs which define a plurality of apertures. The method for controlling the deposition and retention of windblown particles involves using a porous tubular windblown particle control device of this nature. The method also involves locating the control device upwind from an area that is to be protected from the windblown particles, positioning the control device with the longitudinal axis of the porous tubular configuration extending generally parallel to the

earth surface, and orienting the tubular configuration of the sheet of netting material to confront the wind and cause the wind blown particles to flow through the apertures of the sheet of netting material to create aerodynamic effects which deposit and maintain the particles on the

earth surface within the

protected area, which extends upwind and downwind from the tubular control device for a total distance equal to approximately forty times its height.

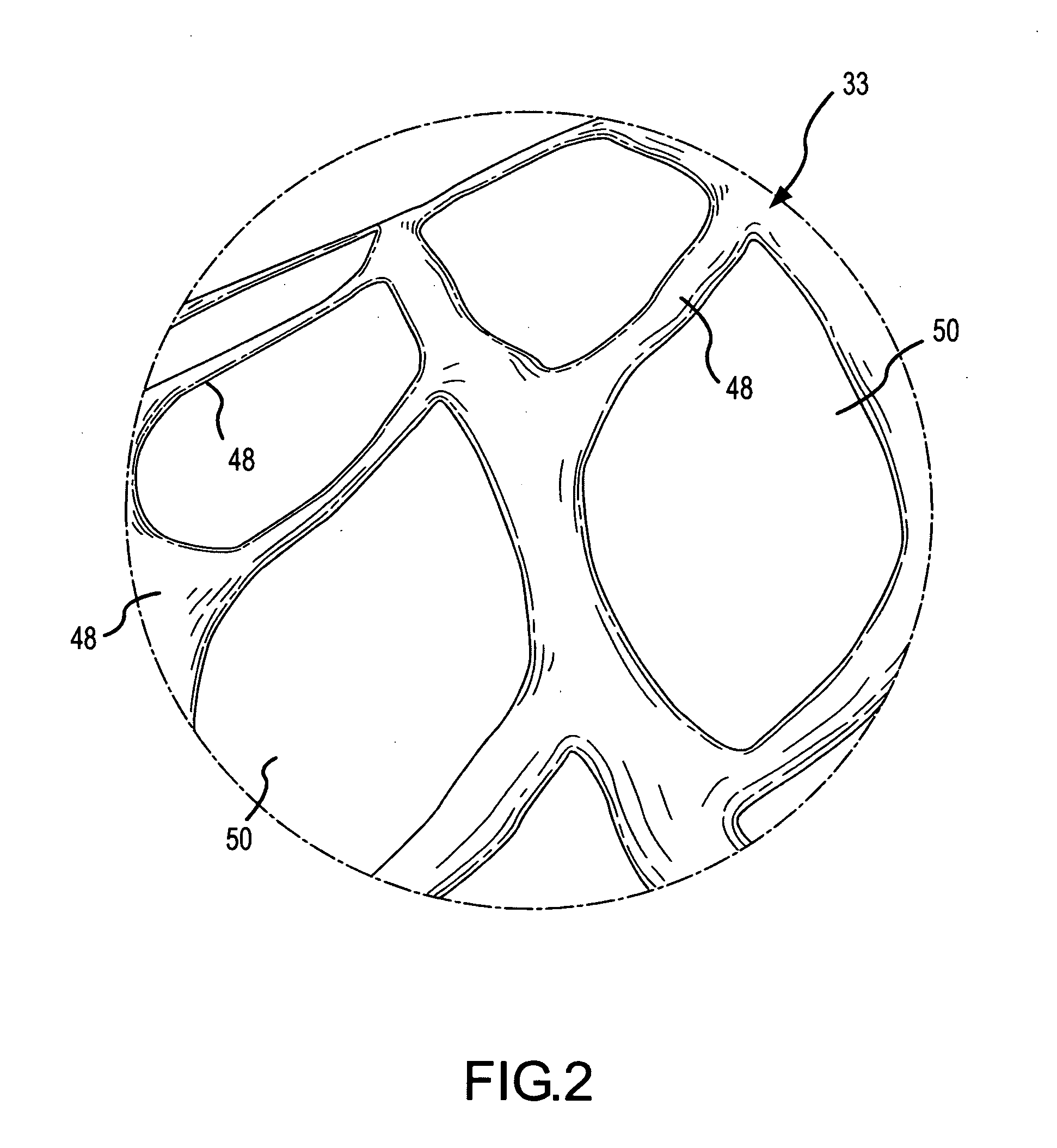

[0011] Preferably, the sheet of netting material is extruded with interconnected webs which each present a three-dimensional characteristic, and the self-supporting strength of the sheet of netting material is imparted by the three-dimensional characteristics of the webs. The strength of the sheet of netting material maintains the tubular configuration without longitudinal bracing between the frame structures, even under the influences of wind loading. The three-dimensional characteristics of the webs and the apertures increase the

aerodynamic drag and enhance the dissipation of the force of the wind on the surface in the vicinity of the tubular device.

[0014] The porous tubular windblown particle control devices are fabricated from relatively inexpensive materials, and each control device can be assembled and disassembled in a relatively quick and efficient manner. As result, the cost of deploying the control device relative to the significant advantages obtained from use of the control devices are substantial. The porous tubular configuration of the control device achieves substantial deposition of windblown particles and stabilization of snowcover, sand or soil, despite its relatively inexpensive nature.

Login to View More

Login to View More  Login to View More

Login to View More