Wall boards or panel boards for use in interior construction and dry construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

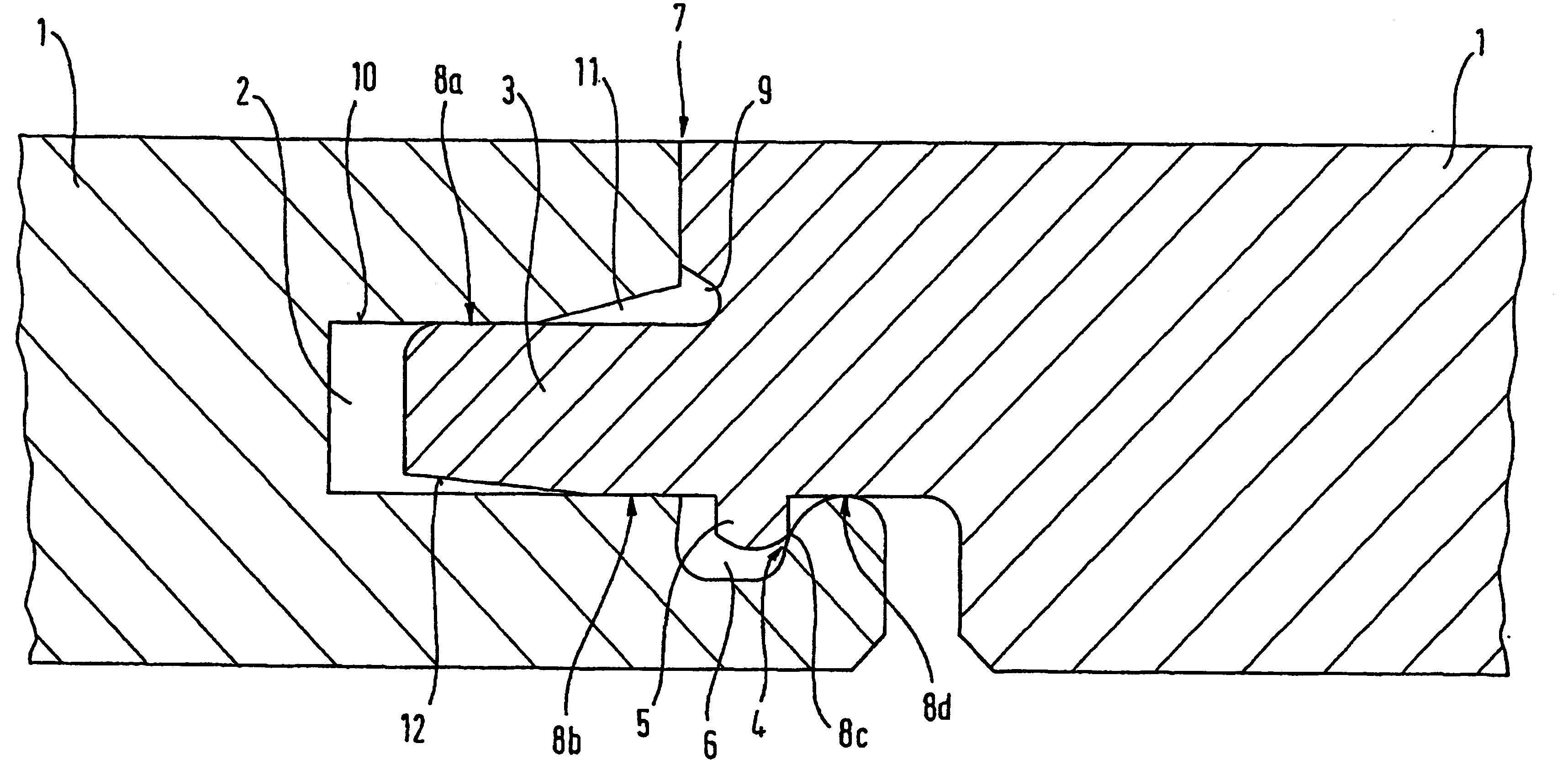

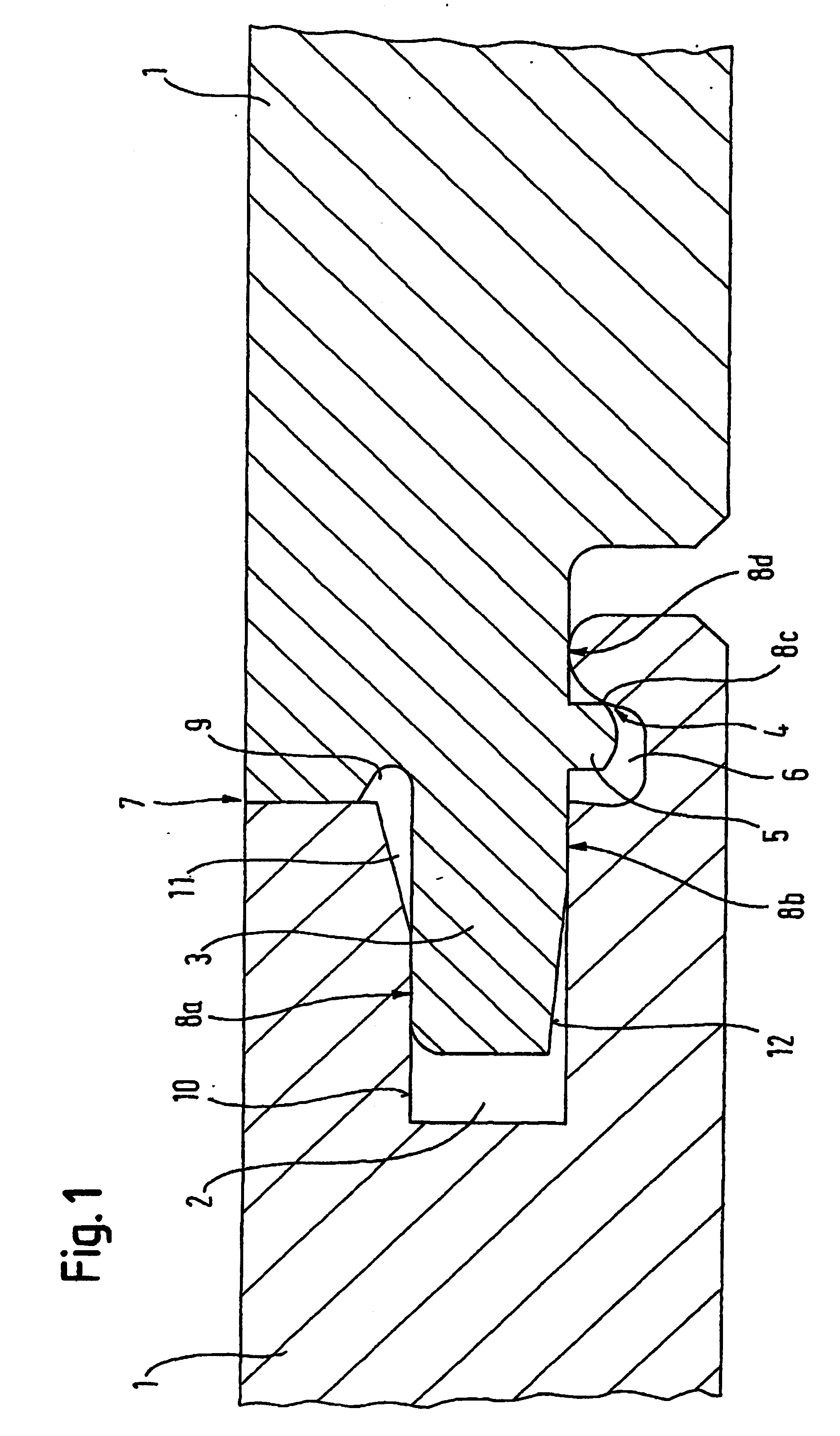

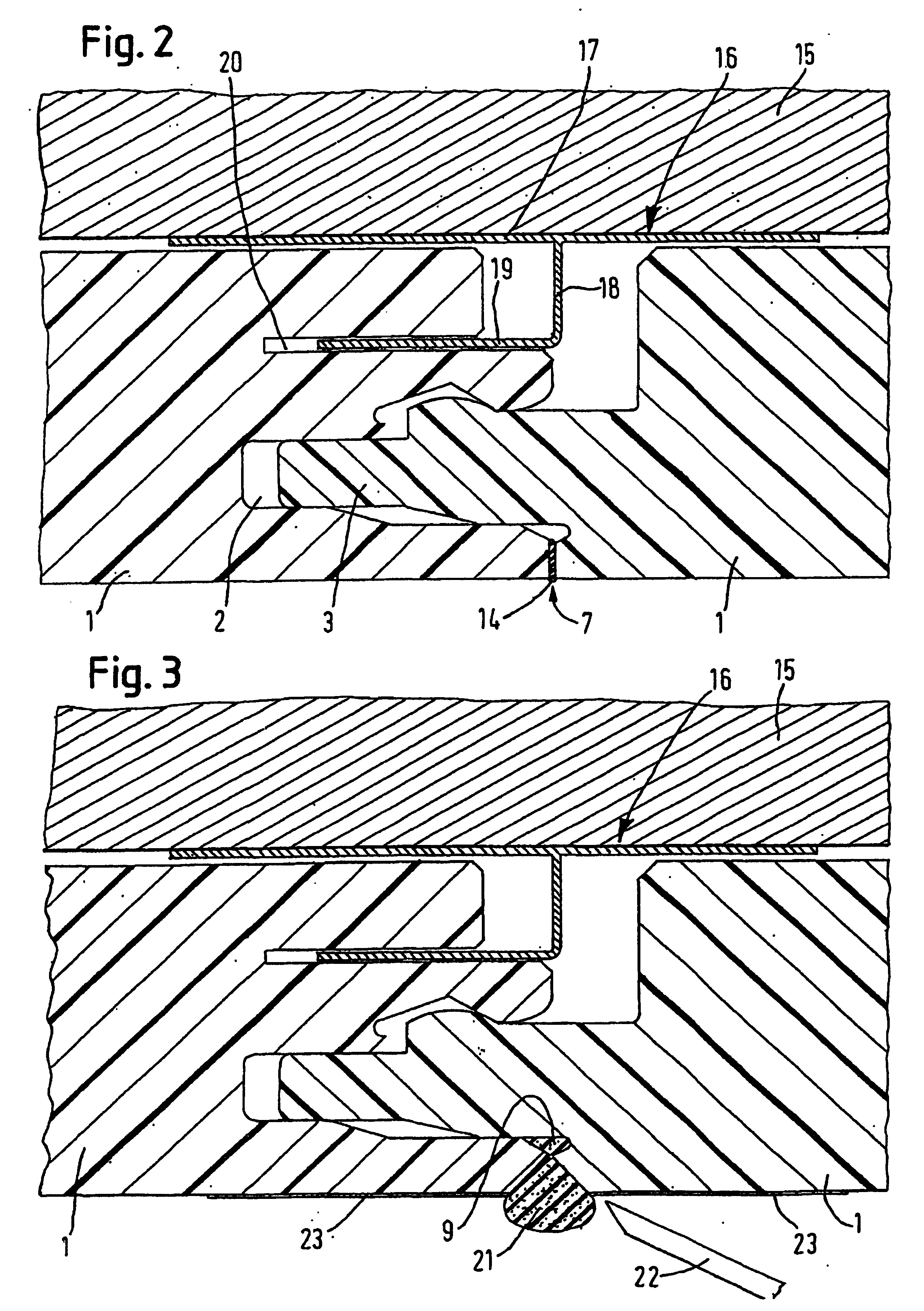

[0078] In the purely schematic FIG. 1, the reference 1 denotes two boards of the same type for interior construction finishing work, the one board 1 having a groove 2 and the other board 1 having a tongue 3 which extends into the groove 2 of the adjacent board 1. The combination of tongue and groove secures the two boards 1 against forces which act transversely relative to the board plane and tend to lift the boards away from a support structure. In the opposite direction, the boards 1 are secured in that they are supported on the support structure, not represented in FIG. 1. It must be mentioned at this point, both for the embodiment shown in FIG. 1 and for all embodiments described in the following, that the surface of the board 1 according to the invention which, in the representation in FIG. 1, is actually the upper surface, is the so-called visible face intended to be directed towards a room interior. This visible face is identifiable in that, at the contact face 7, two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com