Stirling engine having platelet heat exchanging elements

a technology of heat exchange elements and rotating engines, which is applied in the direction of machines/engines, laminated elements, light and heating apparatus, etc., can solve the problems of inefficiency of rotating engines, heat is often not evenly distributed to the working gas within the heater tube, and achieves the effect of running more efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0084] Referring now to FIGS. 8-15, a heat transfer manifold is shown and indicated at 400. The heat transfer manifold 400 is similar to the heat transfer manifold 10 and therefore like elements are numbered alike.

[0085] The heat transfer manifold 400 includes a platelet structure 410 defined by the air / fuel intake platelet zone 210, the air preheat platelet zone 220, the air / fuel mixing platelet zone 230, the combustion platelet zone 240, and the working gas expansion / compression platelet zone 250. In this embodiment, the combustion platelet zone 240 is actually formed by first, second, third, and fourth combustion platelet zones 242, 244, 246, 248, respectively. In addition, the working gas expansion / compression platelet zone 250 is defined by first, second, third, and fourth platelet zones 252, 254, 256, and 258.

[0086] Like the platelet structure 200, the stack of platelets 410 are joined together to form a single monolithic structure. The stack of platelets 410 has a shape whi...

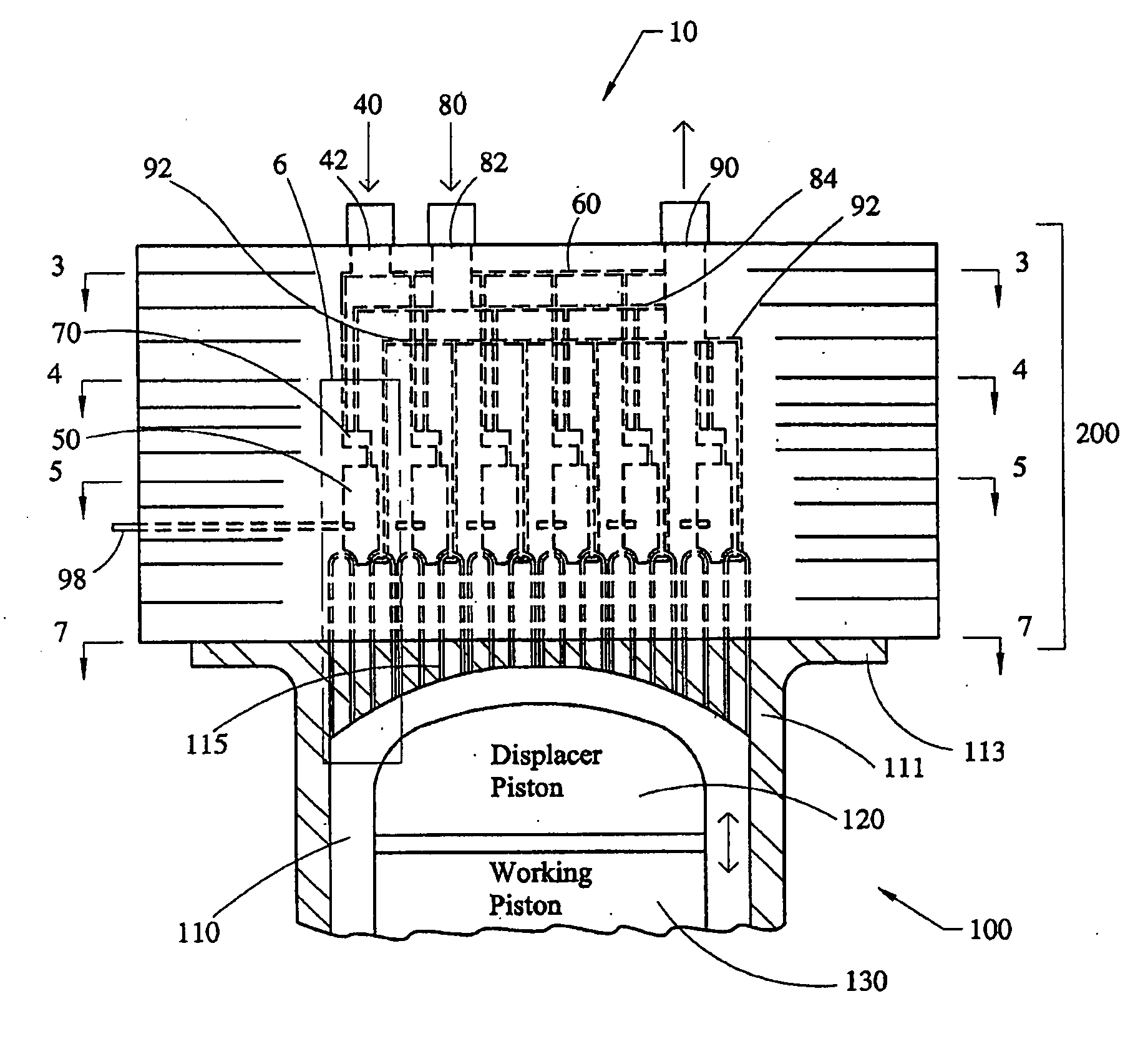

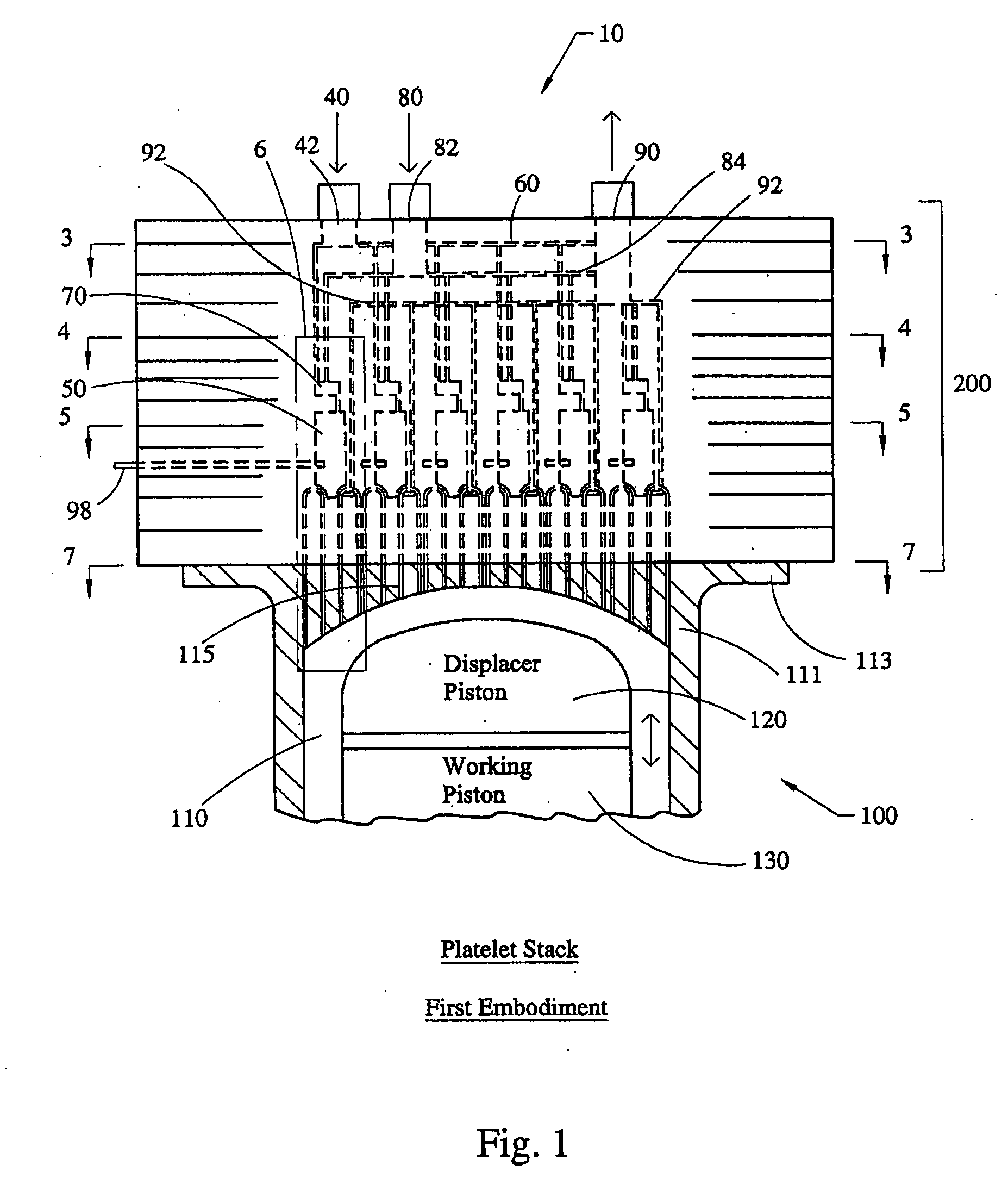

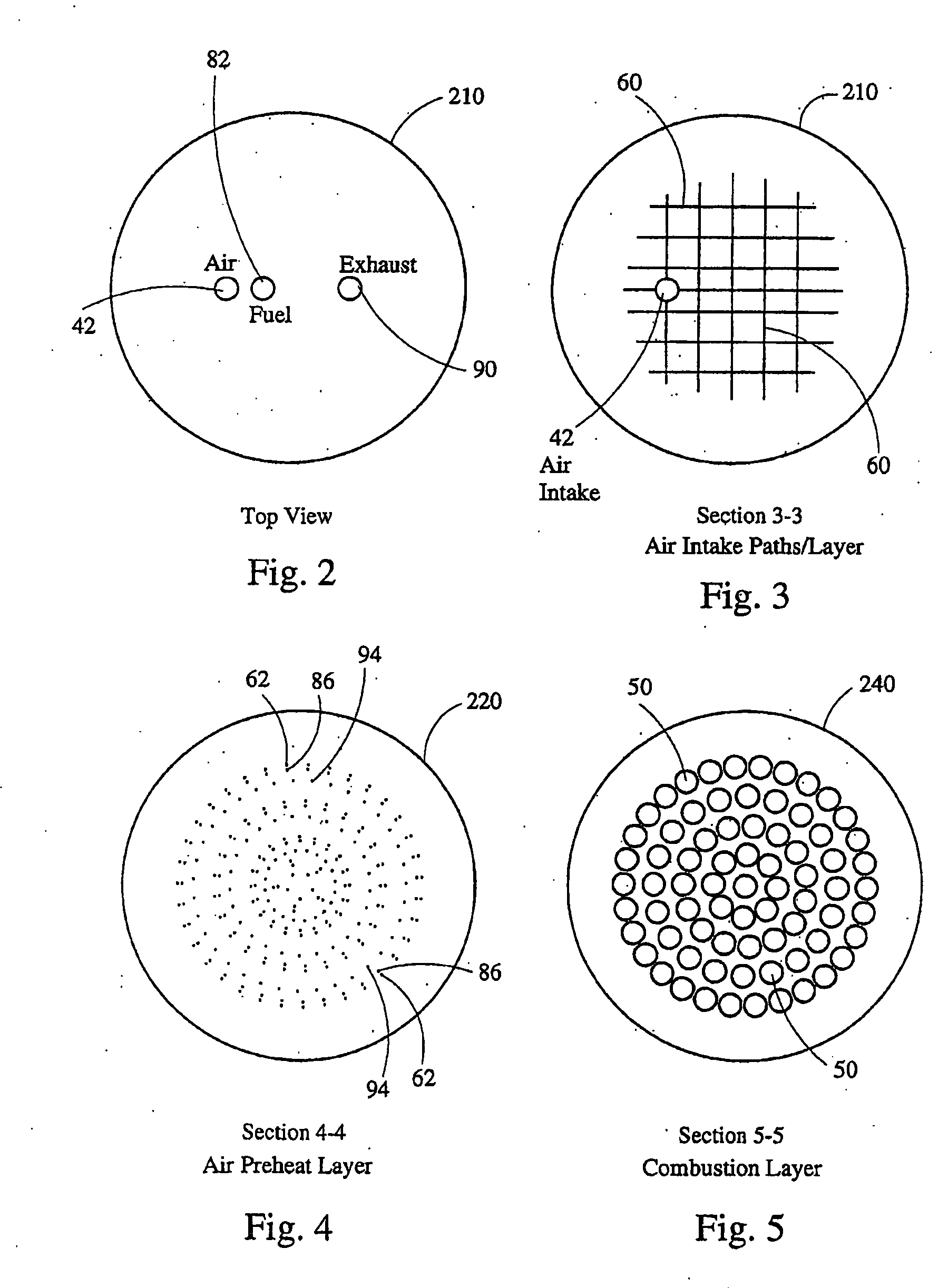

first embodiment

[0133] In the multi-stage combustor system 1000, shown in FIG. 24, a two-stage combustion process without inter-stage cooling is presented. FIG. 24 illustrates generally the heat exchange components of the multi-stage combustor system 1000. The heat exchange components of the multi-stage combustor system 1000 include the first section 760 and the second section 770 (regenerator). The third section 780 (FIG. 16) is not present in this embodiment since this embodiment does not include inter-stage cooling. The first section 760 has a plurality of working gas channels 800 which extend into the second section 770 and also includes a plurality of the combustion gas channels 810.

[0134] The multi-stage combustor system 1000 includes a first (primary) combustor 1010 and a second (secondary) combustor 1020. The first combustor 1010 is coupled to a fuel injection / ignition device 1030. The device 1030 includes a number of fuel channels 1032 and air channels 1034, which serve to provide fuel and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com