Thermodynamic pressure generator

a generator and thermodynamic technology, applied in the field of turbine engines, can solve the problems of near ambient temperature, release of exhaust gases into the atmosphere that are not combustible, etc., and achieve the effects of less fuel consumption, high horsepower, and great torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

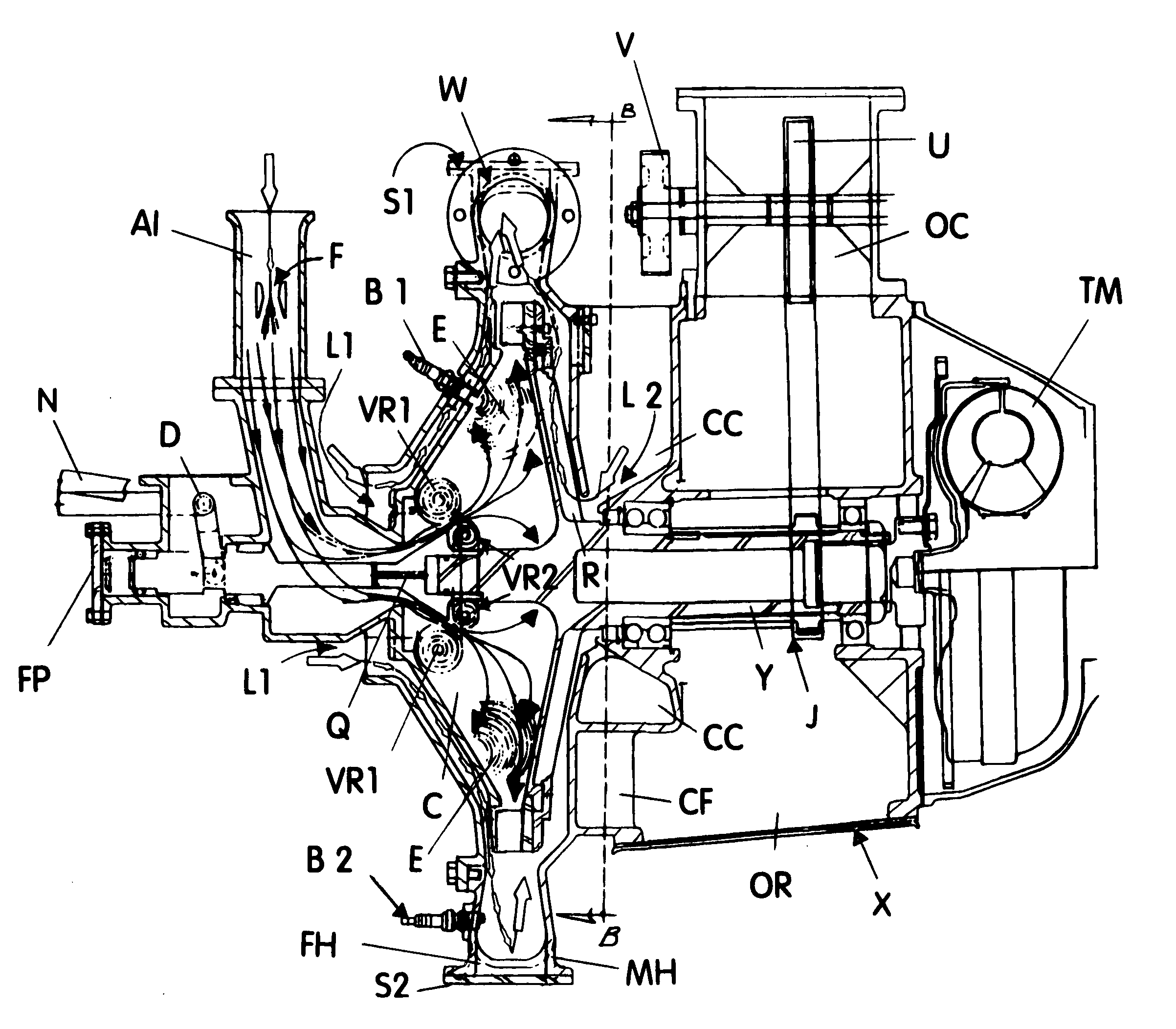

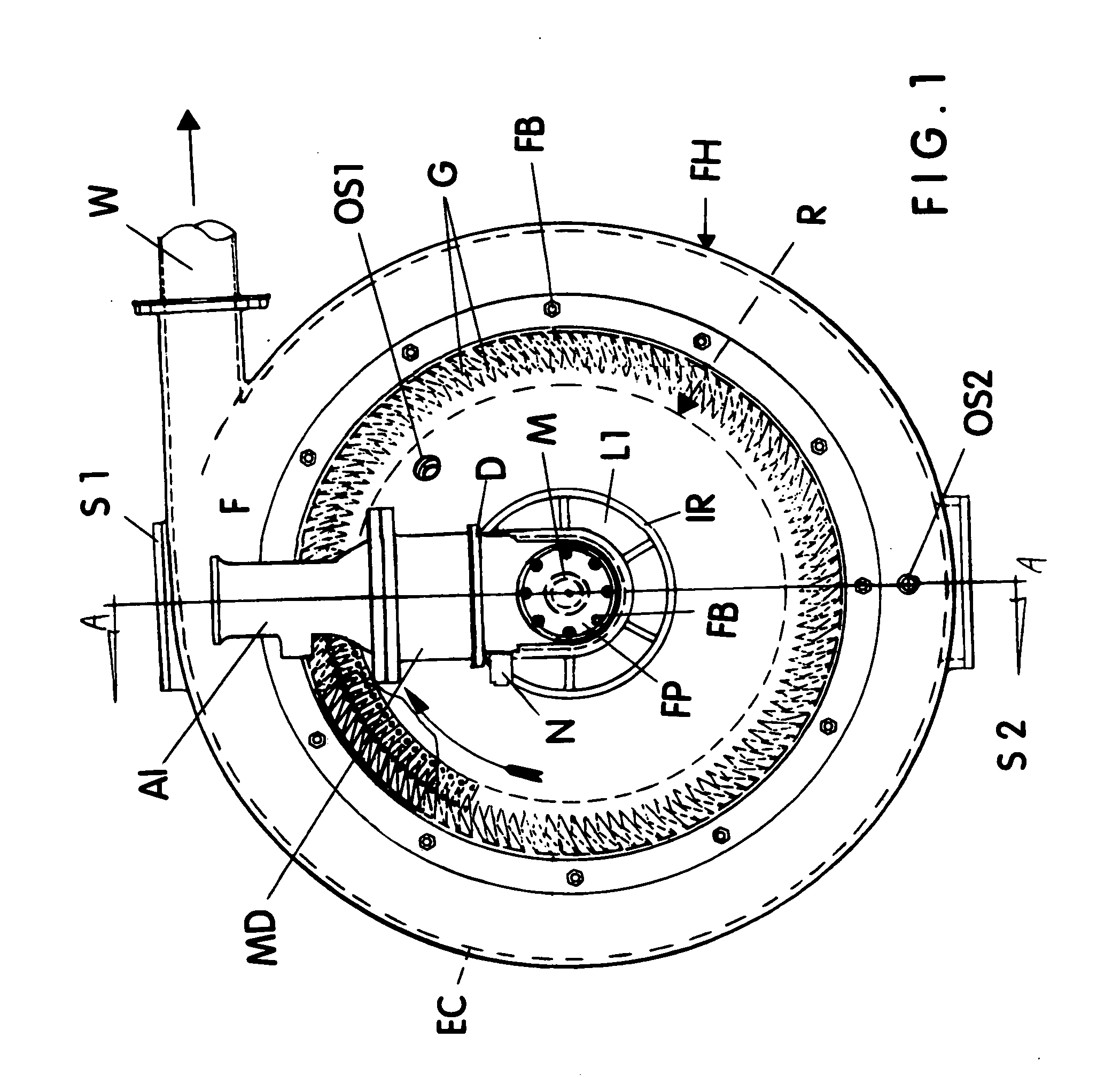

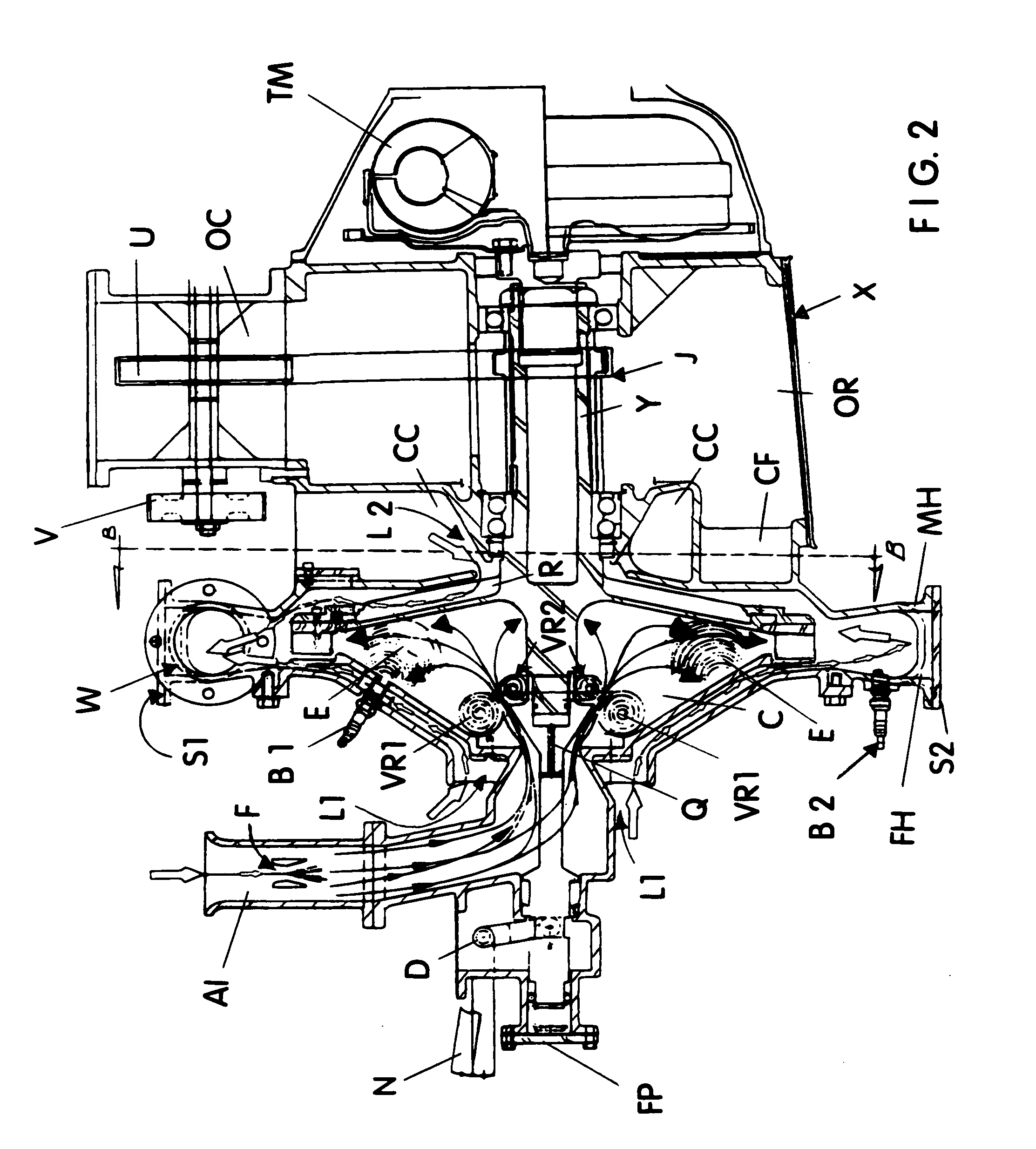

[0017]FIGS. 1-3 show the most preferred embodiment of the present invention turbine engine having an oscillating valve M that allows a premixed fuel mixture (fuel mixture flow is shown by the arrows with solid arrowheads in FIG. 2) to enter a combustion chamber C in turbulence, until it comes into contact with the lips of two annular spoilers A1 and A2, which then convert a portion of the fuel / air mixture into laminar flow in the form of two Karmon vortex rings VR1 and VR2, for delayed ignition. When the remaining turbulent flow is ignited by a continuous spark from igniter B1, a rapid pressure rise occurs that simultaneously kills both vortex rings VR1 and VR2, and the fuel mixture therein goes from laminar to turbulence, adding fuel to the already burning charge E to supercharge it and permit near total ignition. Thus the exhaust gases of the present invention contain no combustible or environmentally polluting by-products. In addition, since the present invention turbine engine a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com