Electrophotographic photoconductor for wet developing and image-forming apparatus for wet developing

a photoconductor and photoconductor technology, applied in the direction of electrographic process apparatus, instruments, corona discharge, etc., can solve the problems of tending to suffer from liquid developer, and achieve excellent sensitivity characteristics, short time, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[First Embodiment]

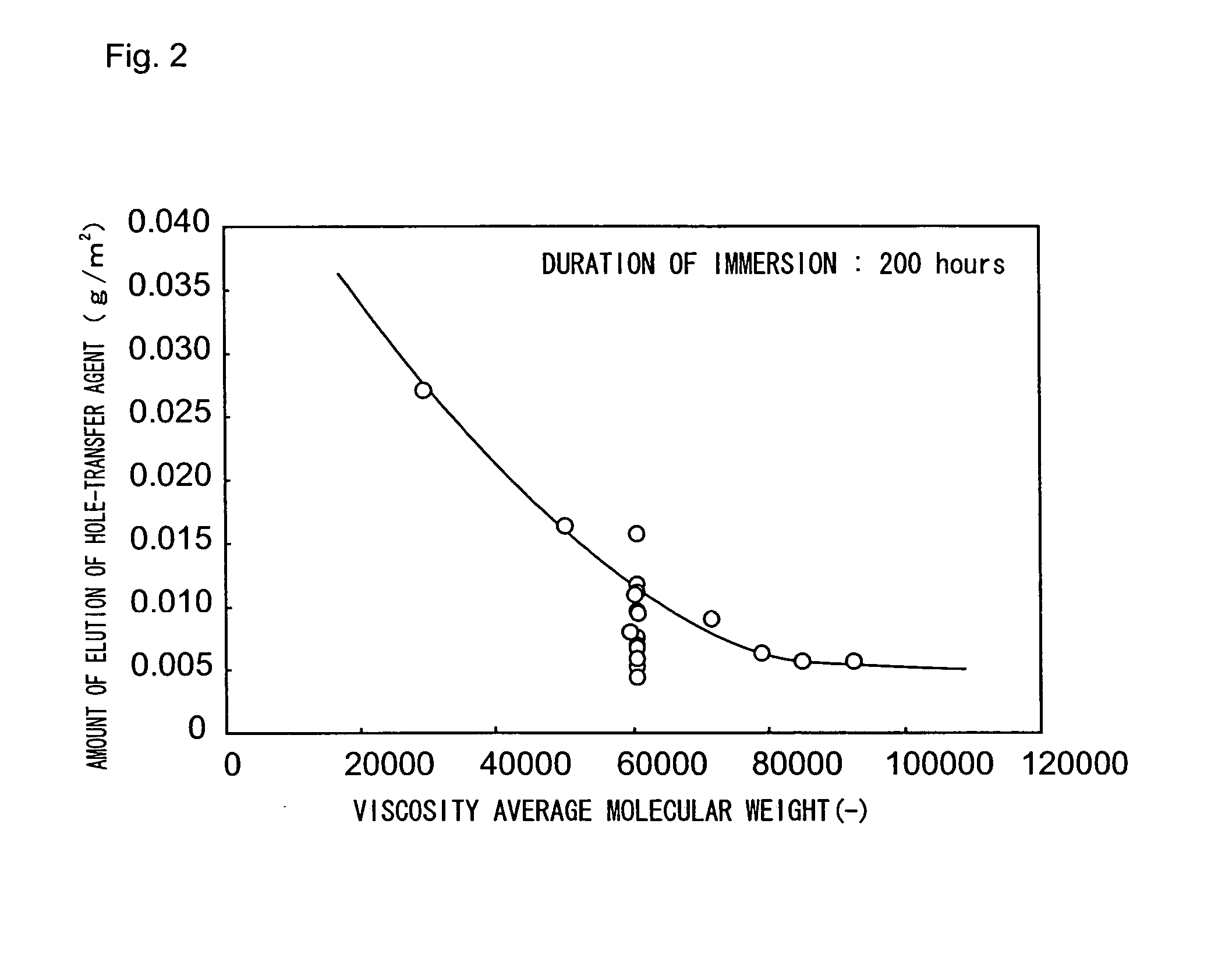

[0036] A first embodiment of the invention is an electrophotographic photoconductor for wet developing having at least a binder resin, a charge-generating agent, a hole-transfer agent and an electron-transfer agent, where the amount of elution of the hole-transfer agent after 2,000-hour-immersion in paraffin solvent having a kinematic viscosity (25° C., in accordance with ASTM D445) of 1.4 to 1.8 mm2 / s is 0.040 g / m2 or less, or the amount of elution of the electron-transfer agent after 2,000-hour-immersion in paraffin solvent having a kinematic viscosity of 1.4to 1.8 mm2 / s is 0.040 g / m2 or less. Here, each of the terms “the amount of elution of the hole-transfer agent” and “the amount of elution of the electron-transfer agent” refer to as the amount thereof eluted per unit area of the electrophotographic photoconductor for wet developing.

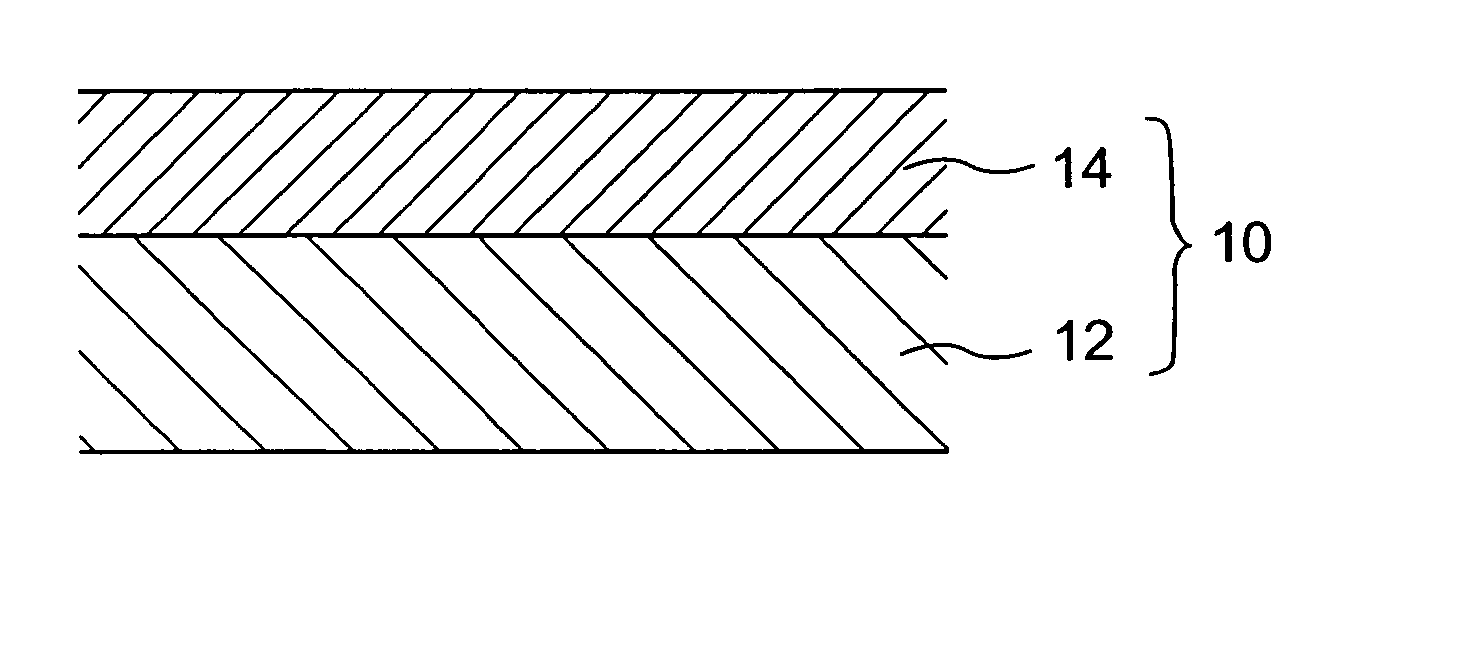

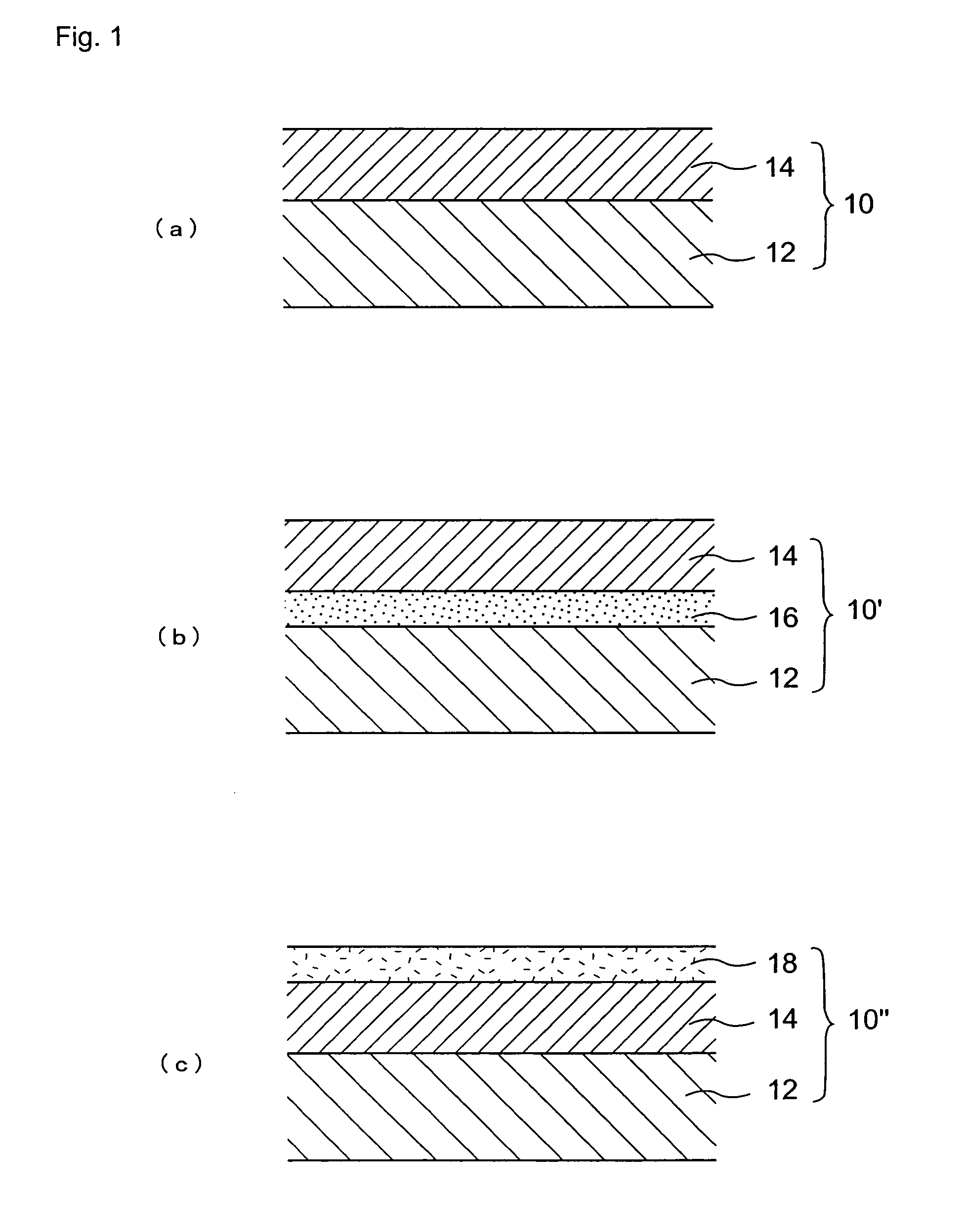

[0037] Furthermore, there are two types of electrophotographic photoconductors for wet developing; those are monotype and lamina...

second embodiment

[Second Embodiment]

[0145] As shown in FIG. 11, a second embodiment of the invention is an image-forming apparatus for wet developing 30 having, in addition to an electrophotographic photoconductor for wet developing (hereinafter, also simply referred to as a “photoconductor”) 31 of the first embodiment, a charging device 32 for effecting a charging step, exposure light source 33 for effecting an exposure step, a wet developing device 34 for effecting a development step, and a transfer device 35 for effecting a transfer step arranged around the photoconductor 31, where a liquid developer 34a having toner dispersed in a hydrocarbon-based solvent is used to form images in the development step.

[0146] Incidentally, the image-forming apparatus for wet developing will be described below on the assumption that a monolayer photoconductor would be used as an electrophotographic photoconductor for wet developing.

[0147] The photoconductor 31 revolves at a constant speed in the direction as th...

example 1

(1) Production of Electrophotographic Photoconductor for Wet Developing

[0151] In an ultrasonic dispersing machine, 4 parts by weight of X-type metal-free phthalocyanine (CGM-1) that is one of compounds represented by the formula (3) as a charge-generating agent, 40 parts by weight of a stilbenamine derivative (HTM-1) that is one of compounds represented by the formula (19) as a hole-transfer agent, 40 parts by weight of a naphthoquinone derivative (ETM-1) that is one of compounds represented by the formula (8) as an electron-transfer agent, 100 parts by weight of a polycarbonate resin (Resin-1) with a viscosity average molecular weight of 50,000 represented by the formula (20) below as a binder resin, 0.1 parts by weight of KF-96-50CS (dimethylsilicone oil; Shin-Etsu Chemical) as a leveling agent, and 750 parts by weight of tetrahydrofuran as a solvent were accommodated, followed by mix and dispersion by 60-minute ultrasonic-treatment to produce a coating solution.

[0152] The resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com