Solid-state rotational rate sensor device and method

a piezoelectric rate and sensor device technology, applied in the direction of acceleration measurement using interia force, speed measurement using gyroscopic effects, electric/magnetic means, etc., can solve the problem of less accuracy of vibrational motion control by single-ended actuators, responsive amplitude of secondary vibration, etc., to improve immunity and increase the overall device and system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention provides a solid-state rotational rate sensor device formed by thin films for generating an electrical signal output proportional to the rate of rotational motion. The precision thin-film piezoelectric elements are configured and arranged on a semi-rigid structure to detect rotation (such as pitch, roll, and yaw) while rejecting spurious noise created by vibration, thermal gradients, and electromagnetic interference.

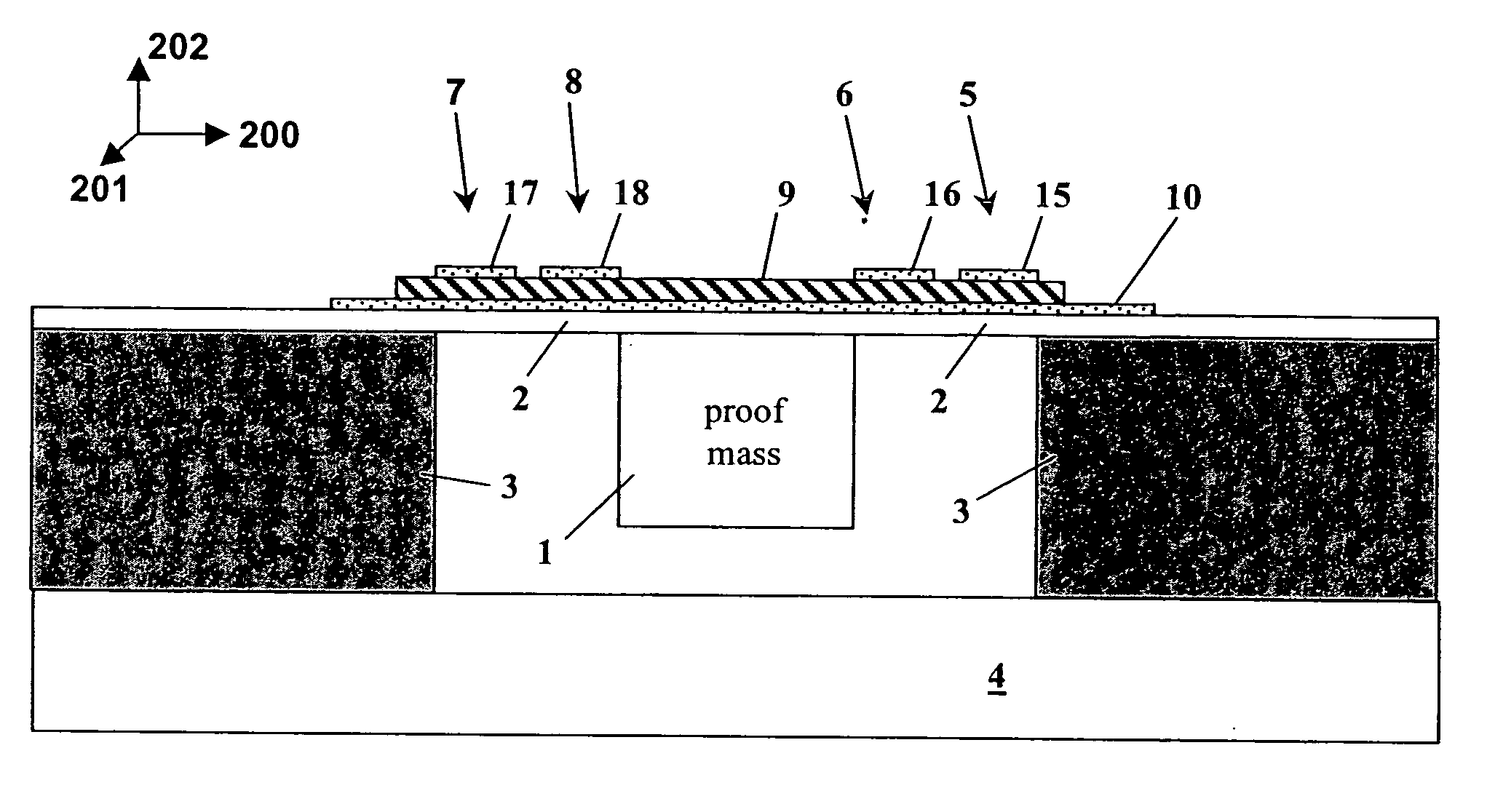

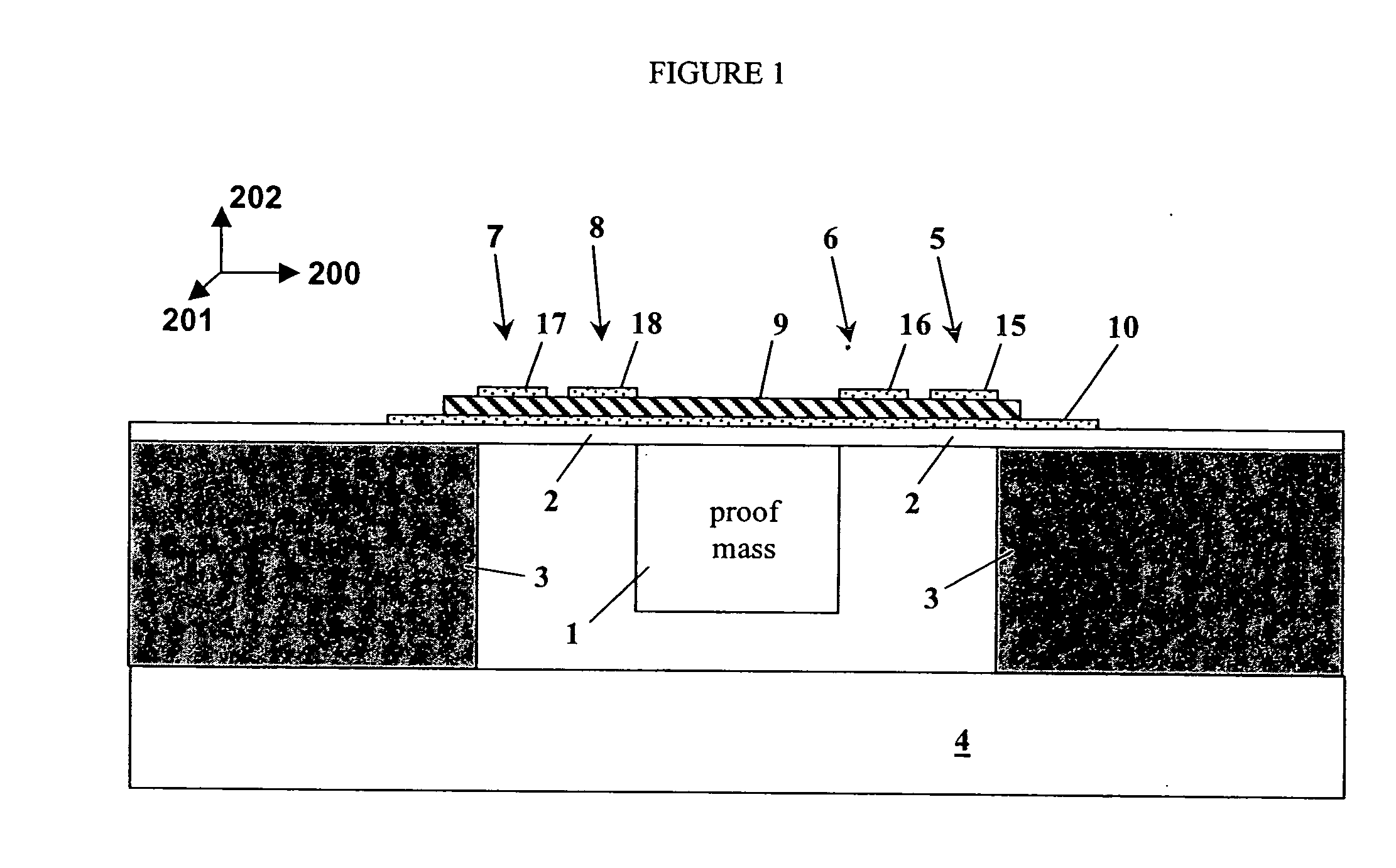

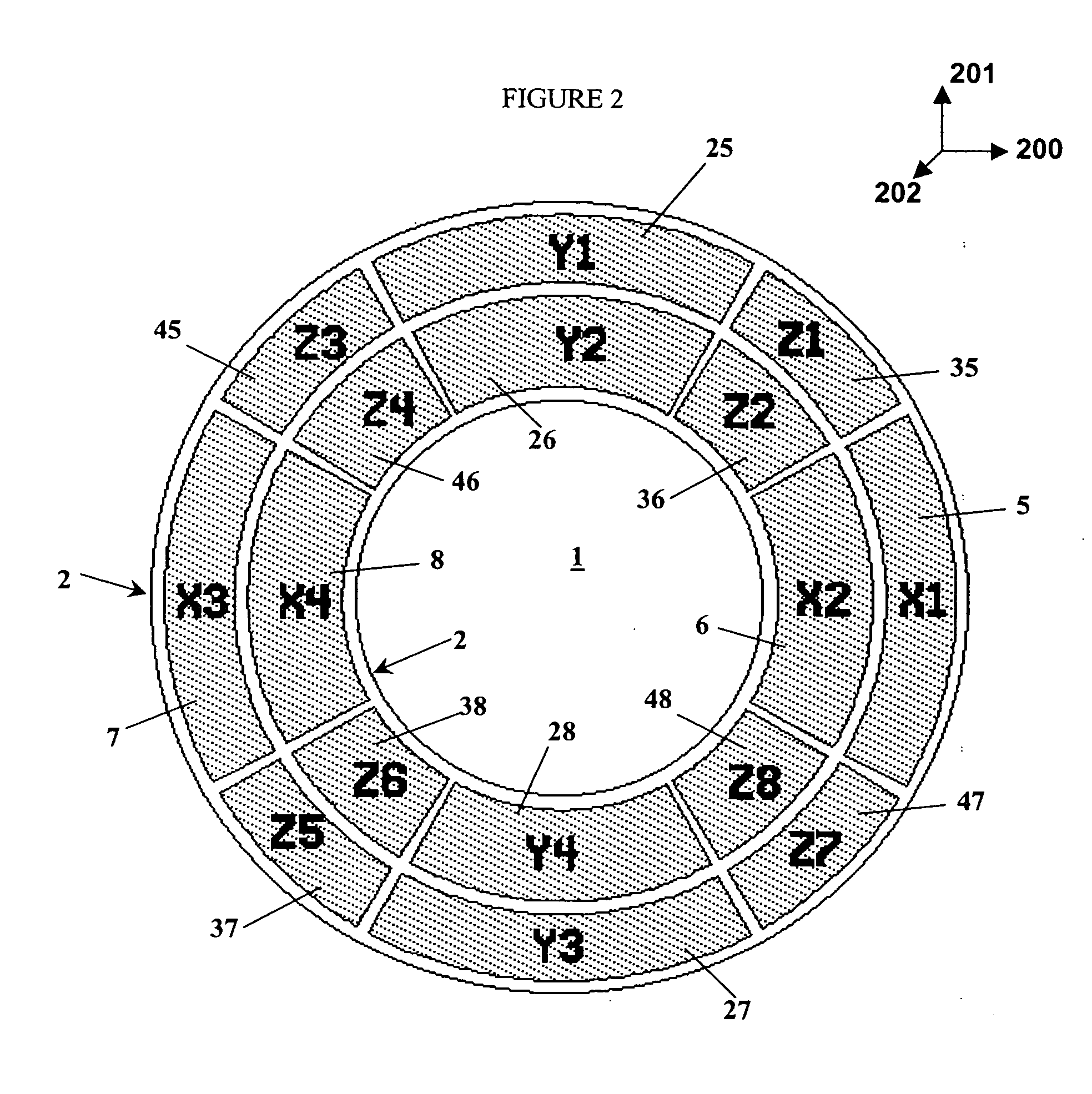

[0033] The main features of one embodiment of a rotational rate sensor device (also referred to as “gyro”) are shown in FIG. 1. The device includes a) a cylindrical silicon proof-mass 1 that is suspended on b) a toroidal thin-film membrane 2 on which are c) a series of thin-film piezoelectric elements 5, 6, 7, and 8. Typically, the height of the proof-mass 1 is about 500 microns, the diameter of the proof-mass 1 is about 400 microns, while the outer diameter of the membrane 2 toroid is about 700 microns. The membrane 2 can be realized with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com