Titanium aluminide intermetallic composites

a technology of titanium aluminide and intermetallic composites, which is applied in the field of titanium aluminide intermetallic composites, can solve the problems of increased porosity, inability to fully activate combustion synthesis, and significant detrimental effect on the mechanical properties of the material, and achieves cost-prohibitive tac production for most applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

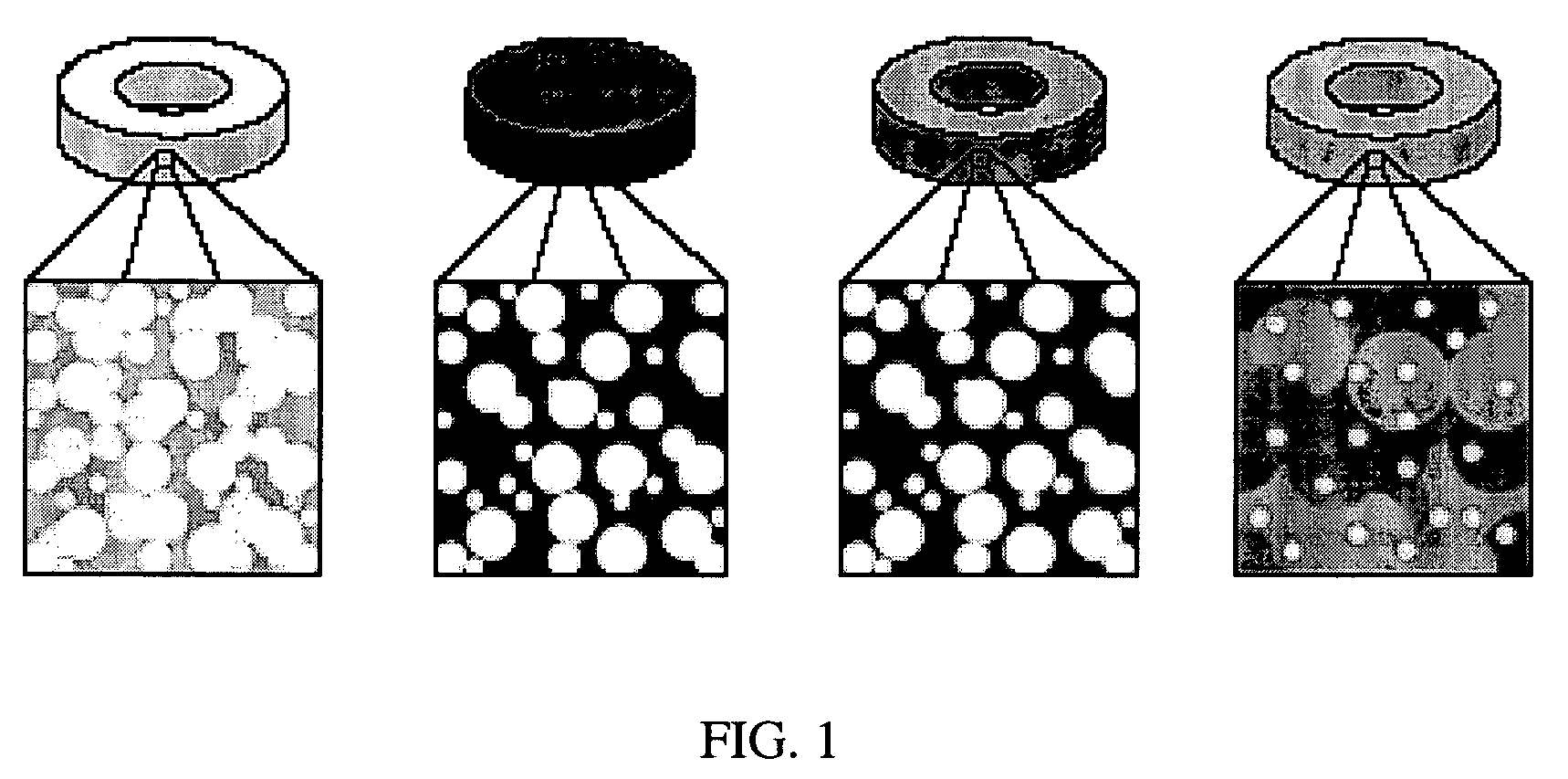

Image

Examples

example 1

[0027] Following the reaction of Equation 2, a porous preform is fabricated to define a part shape and comprises lithium titanate having a volume fraction of 55.9% (the rest of the preform is air). The porous preform is infiltrated with aluminum and heated to about 850° C. to melt the aluminum and maintain. sufficient heat to allow the reaction to be initiated and completed. The lithium titanate reacts with the aluminum to form a post-combustion intermetallic composite comprising 62.3% LiAlO2 by volume fraction and 37.9% of a solid solution of a LixTiyAlz matrix. As discussed generally above, most of the matrix is γ-TiAl. That is, most of the solid solution would be just γ-TiAl, but excess lithium would occasionally replace a few aluminum atoms in the crystal structure of the matrix.

example 2.example 2

[0028] Example 2. Example 2 is similar to Example 1 but with the addition of Saffil High Alumina Fibre. This requires adjustments to the amounts of materials in the preform as follows: Lithium titanate: 47.6% by volume fraction, aluminum: 37.4% by volume fraction, Saffil High Alumina Fibre: 15% by volume fraction. The post-combustion intermetallic composite comprises 53.5% LiAlO2 by volume fraction, 32.3% of a solid solution of a LixTiyAlz matrix, and 14.2% High Alumina Fibre. The volume fractions are adjusted based on volumetric expansion.

example 3

[0029] A zero porosity titanium aluminide intermetallic composite is created from a preform comprising: TiO2: 24.3% by volume fraction, Lithium titanate: 26.3% by volume fraction, aluminum: 49.4% by volume fraction. The post-combustion intermetallic composite is optimized to avoid a significant change in density, and comprises: 41.7% LiAlO2, 43.3% TiAl matrix, and 15% Al2O3 by volume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| volume fraction | aaaaa | aaaaa |

| volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com