Device and method for electrochemical reduction

a technology of electrochemical reduction and device, which is applied in the direction of electrochemical machining apparatus, metal-working apparatus, manufacturing tools, etc., can solve the problems of uneven removal, deviation of the achieved shape from the desired shape of the workpiece, and non-uniform distribution of the removal products of the workpiece in the electrolyte, etc., to achieve the effect of increasing the processing precision of electrochemical reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

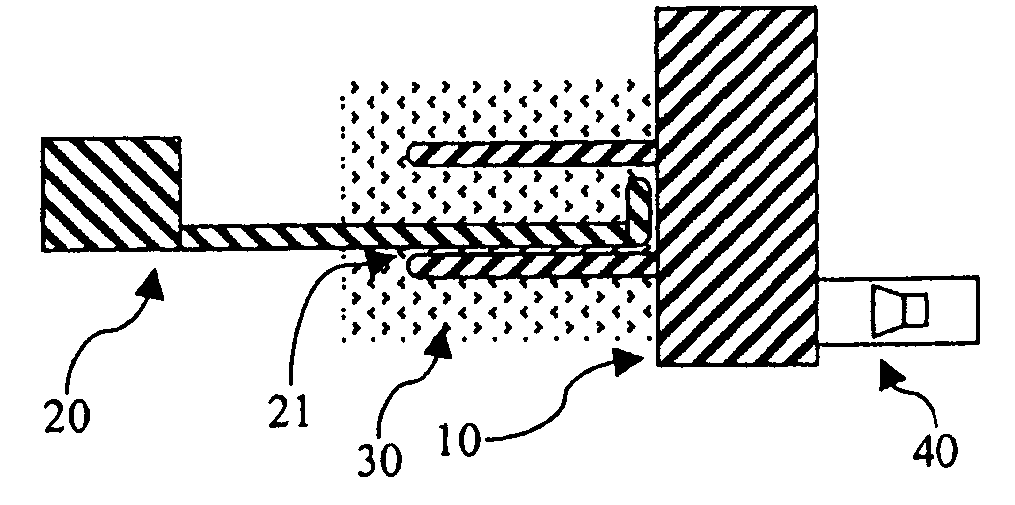

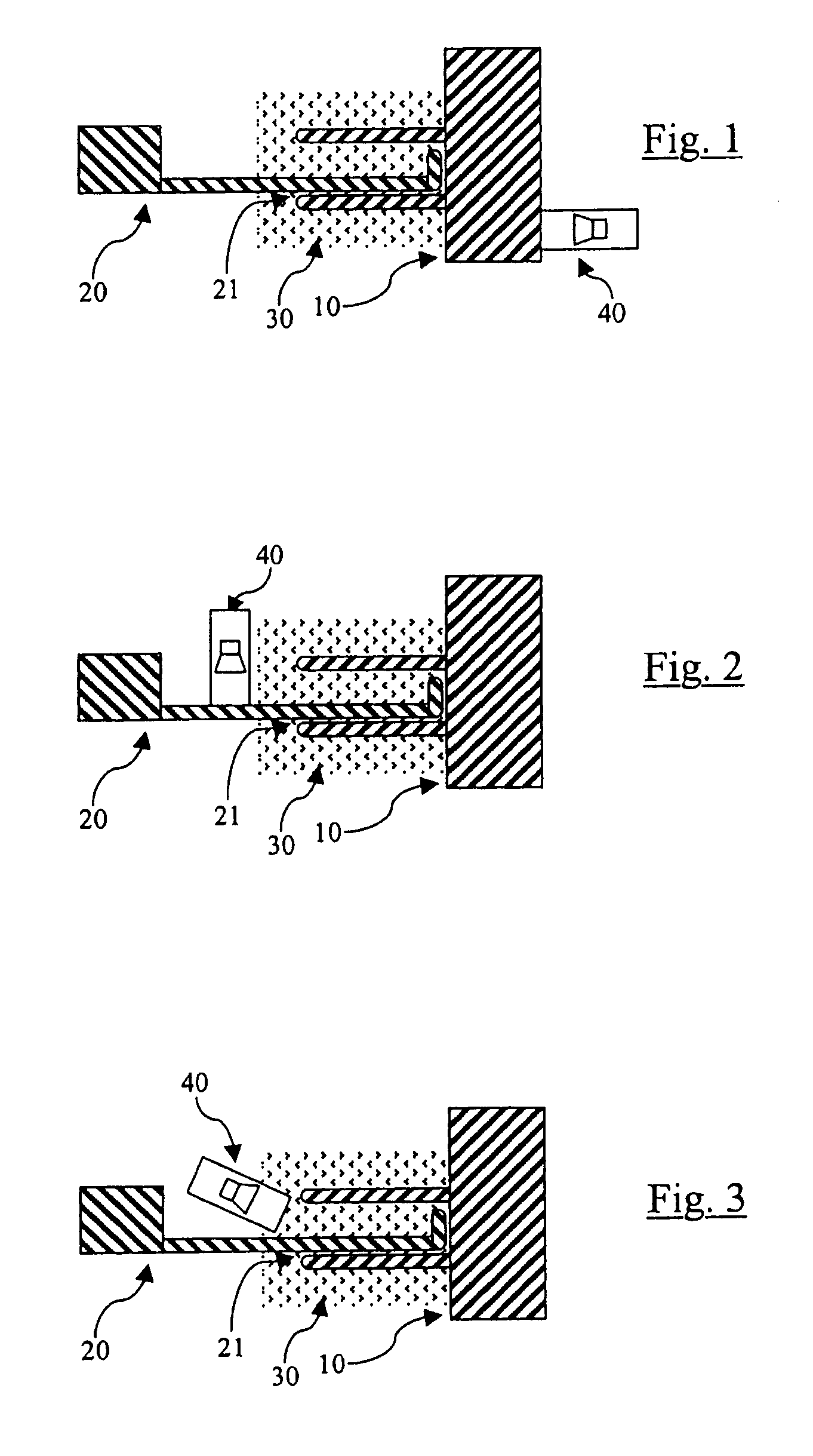

[0024]FIGS. 1 through 3 show a schematic representation of devices according to the present invention for electrochemical reduction using a sonotrode to introduce sound waves, the sonotrode being positioned in different areas.

[0025]FIG. 1 shows a schematic arrangement in which the sonotrode is positioned in the processing area of the workpiece; FIG. 2 shows an arrangement in which the sonotrode is positioned in the electrode; and FIG. 3 shows a schematic representation of an exemplary embodiment in which the sonotrode couples the sound waves directly into the electrolyte.

[0026] All three figures show a workpiece 10 which is processed by electrochemical reduction. To this end electrode 20 is guided relative to the workpiece, while a reduction gap 21 is maintained with the smallest possible gap dimension between electrode 20 and workpiece 10. In addition, there is an electrolyte 30 at least in the area of reduction gap 21. To carry out the reduction process, a current flows between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gap dimension | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com