Gallium-nitride based light emitting diode light emitting layer structure

a technology of light-emitting diodes and gallium nitride, which is applied in the direction of nanotechnology, electrical equipment, semiconductor devices, etc., to achieve the effects of improving the lighting efficiency of gan-based leds, facilitating the growth of epitaxial layers, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

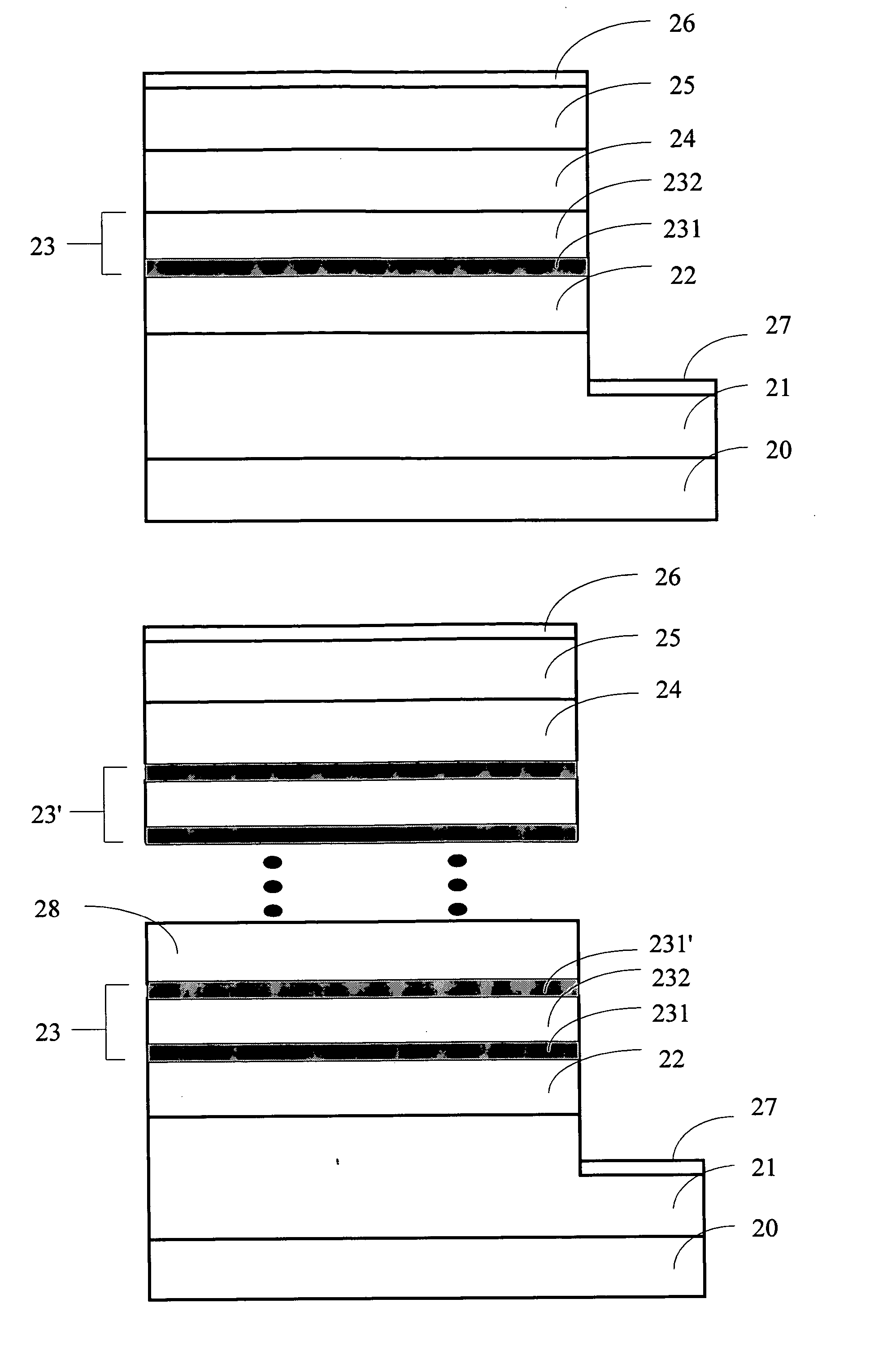

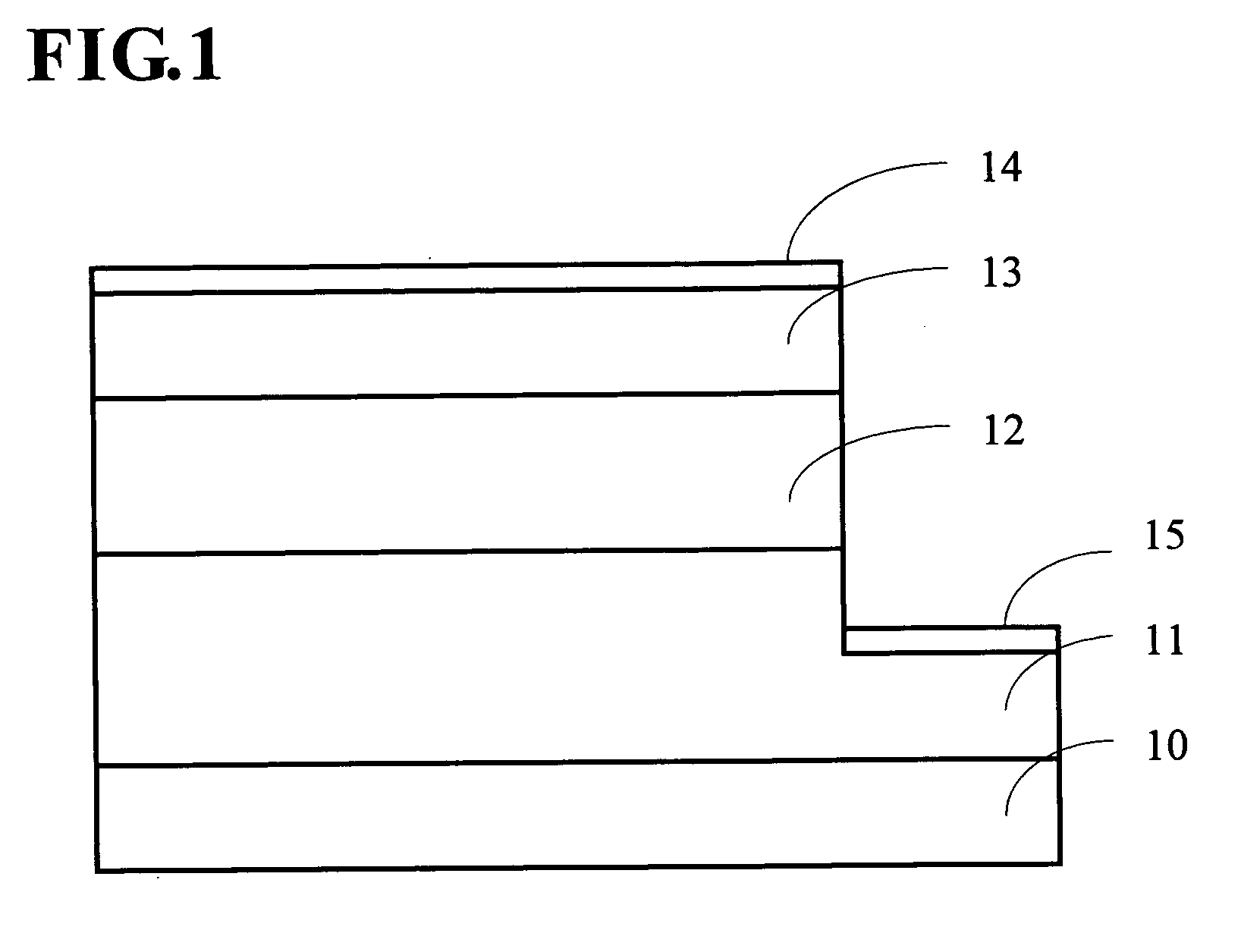

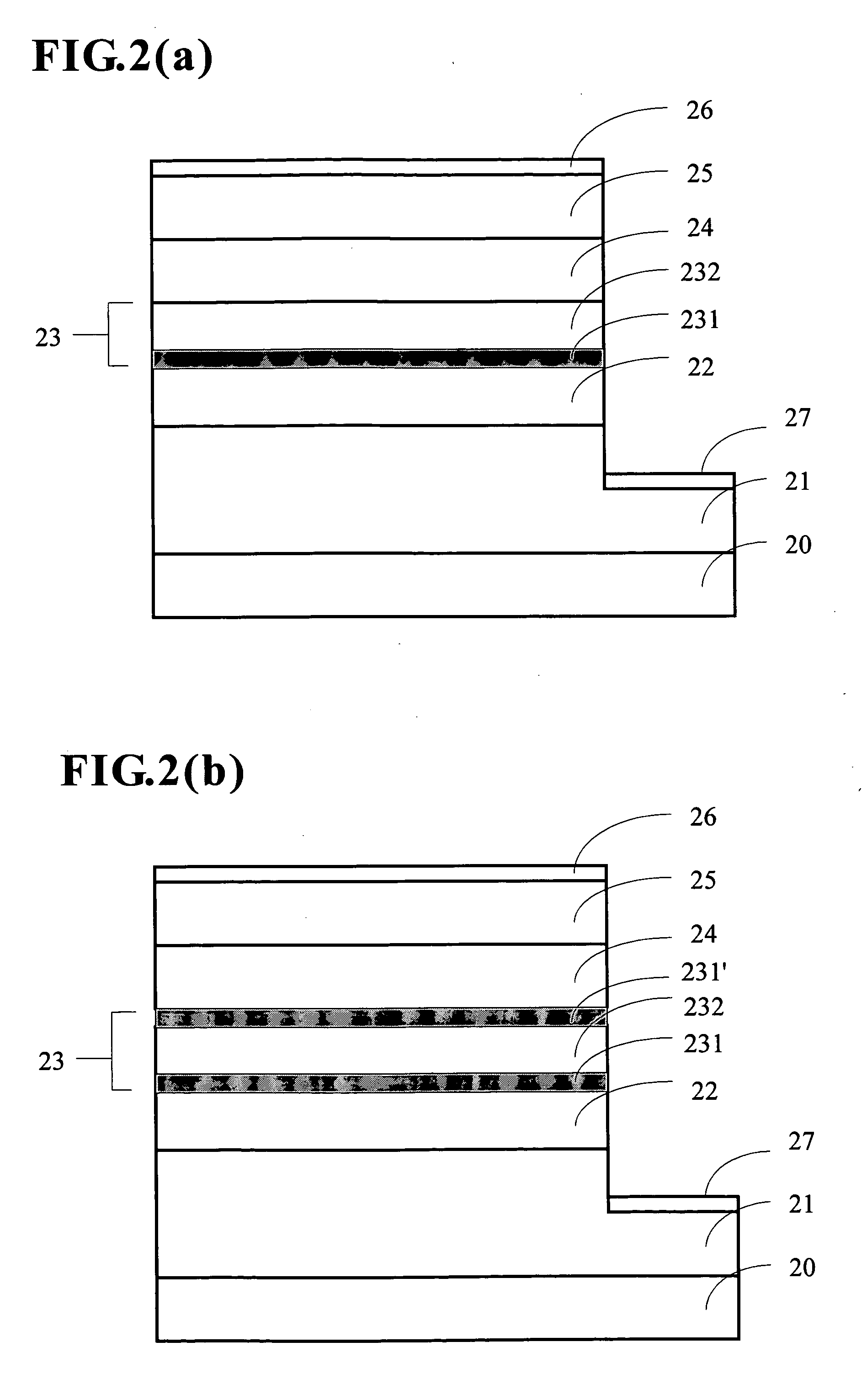

[0015] FIGS. 2(a), 2(b), and 2(c) are schematic diagrams showing the GaN-based LED structures according to a first embodiment of the present invention. As shown in FIGS. 2(a), 2(b), and 2(c), the GaN-based LED structures use sapphire as the substrate 20. Then, sequentially from bottom to top on the sapphire substrate 20, the GaN-based LED structures contain a n-type GaN contact layer 21, a lower barrier layer 22 made of un-doped aluminum-gallium-indium-nitride (Al1-x-yGaxInyN, 0≦x,y≦1, x+y≦1), at least an intermediate layer 23, an upper barrier layer 24 made of un-doped Al1-p-qGapInqN (0≦p,q≦1, p+q≦1), and a p-type GaN contact layer 25. The GaN-based LED structures further contain a positive electrode 26 and a negative electrode 27 on top of the p-type GaN contact layer 25 and the n-type GaN contact layer 21 respectively.

[0016] As shown in FIG. 2(a), the intermediate layer 23 further contains, from bottom to top, an ultra-thin quantum-dot layer 231 made of indium-nitride (InN) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com