In-process vision detection of flaws and FOD by back field illumination

a back field illumination and in-process technology, applied in the direction of investigating composite materials, controlling lamination, transportation and packaging, etc., can solve the problems of foreign objects and debris (fod), such as resin balls and fuzz balls, that can accumulate foreign objects and debris during the placement of composite strips on the underlying composite structure, and achieve the effect of simplifying the composite structure inspection process and minimizing the time involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

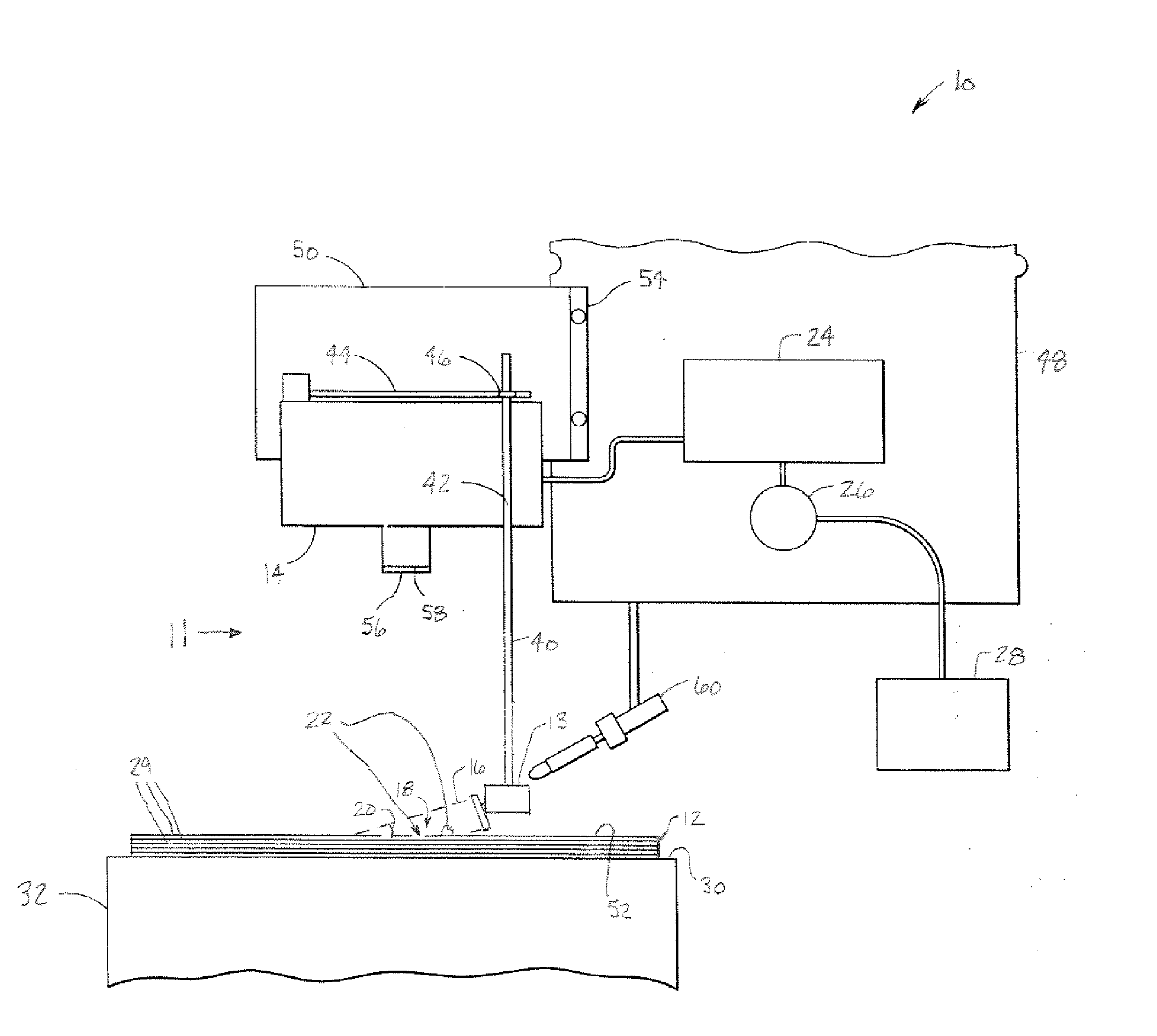

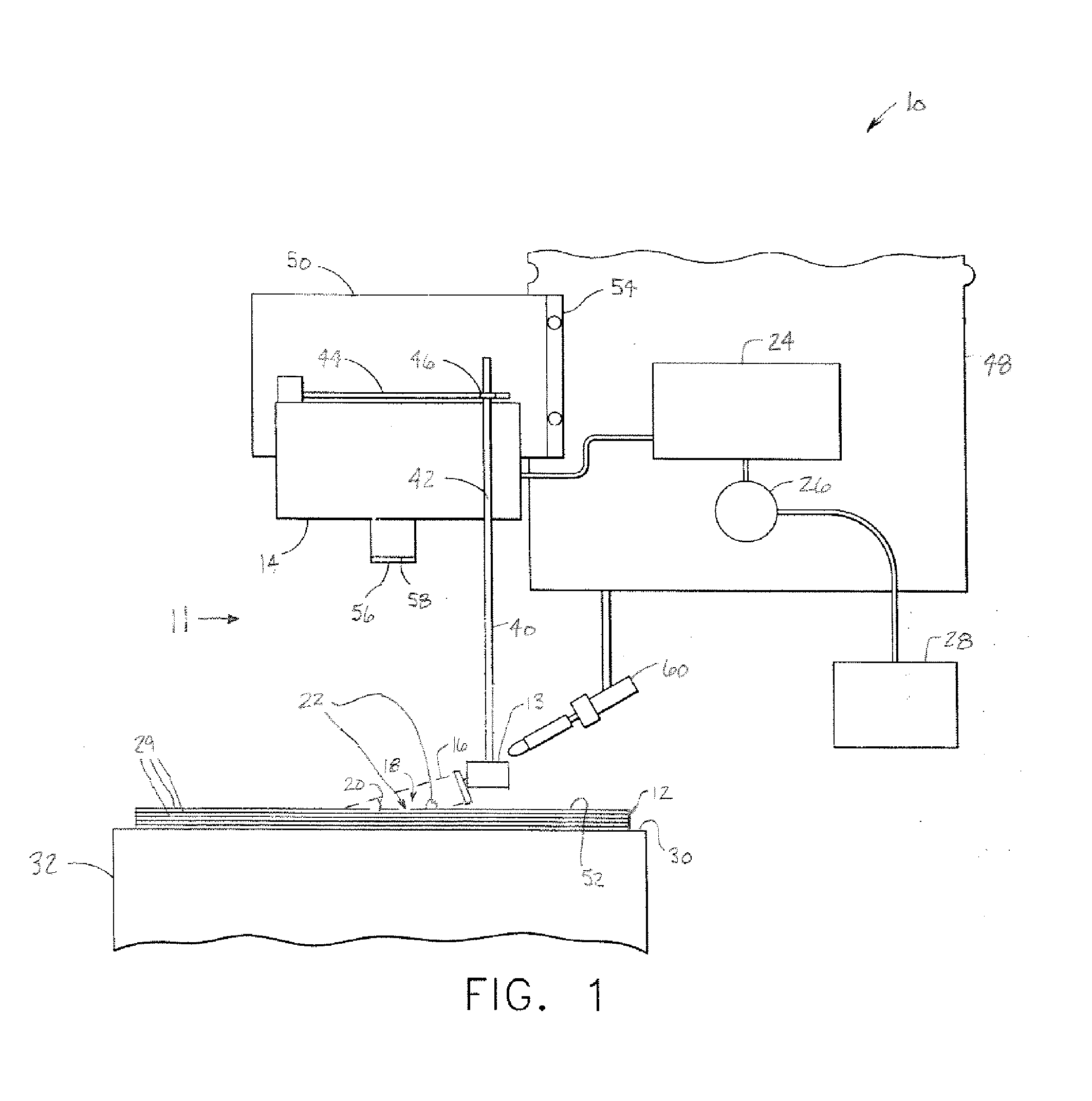

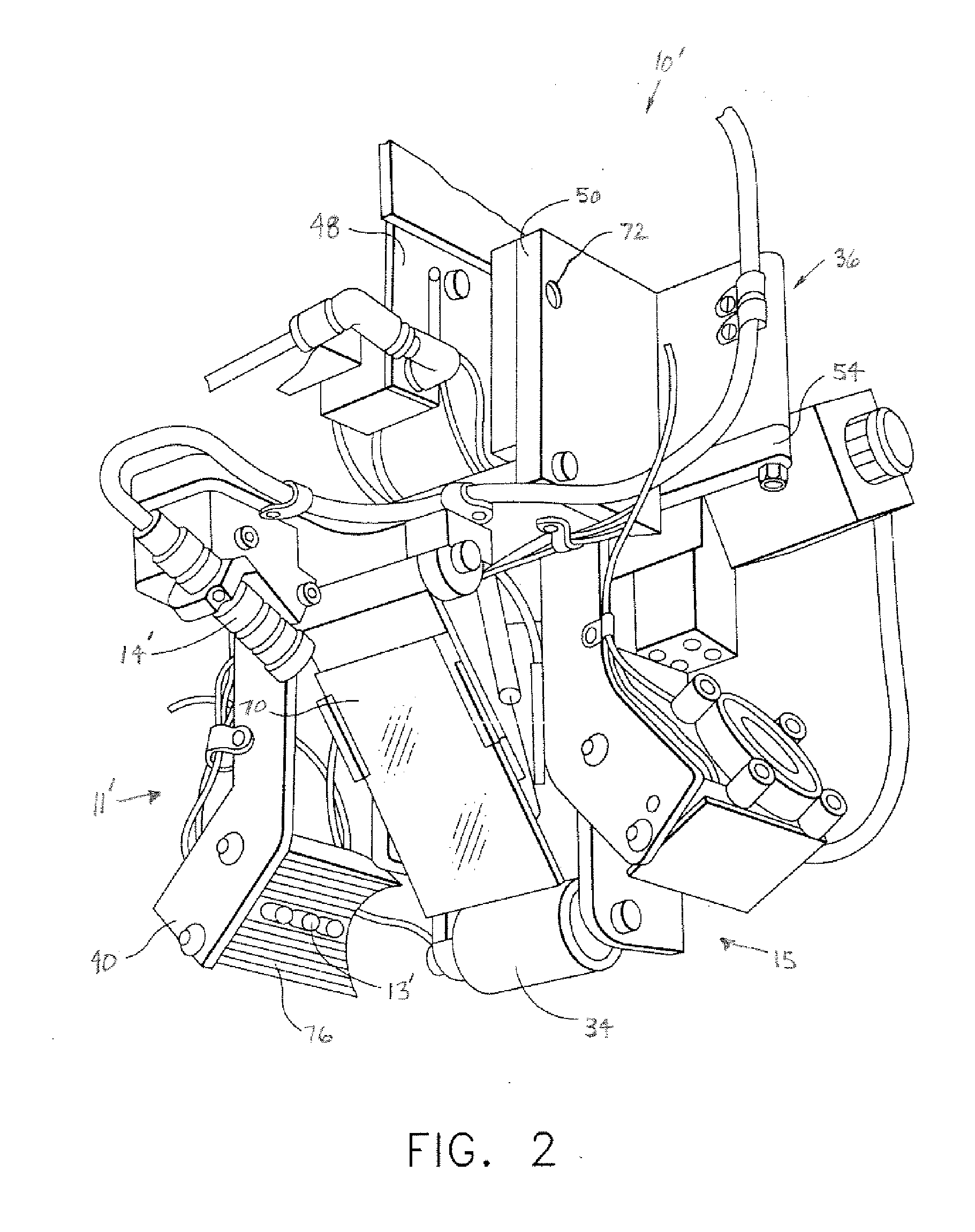

[0024] In each of the following Figures, the same reference numerals are used to refer to the same components. While the present invention is described with respect to systems and methods of detecting flaws and foreign object debris (FOD) during the fabrication of a composite structure, the present invention may be adapted for various applications and systems, such as fabrication of structures and components, production line applications, or other applications and systems known in the art. The present invention may be applied to both the fabrication of aeronautical and non-aeronautical systems and components.

[0025] In the following description, various operating parameters and components are described for one constructed embodiment. These specific parameters and components are included as examples and are not meant to be limiting.

[0026] Also, in the following description the term “foreign object debris (FOD)” refers to any resin ball, fuzz ball, impurity, or other foreign or undes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| acute angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com