Novel dosage form

a dosage form and a new type of technology, applied in the field of dosage forms, can solve the problems of high active ingredient concentration, difficult to achieve the effect of reducing the size of the dosage form, and reducing so as to achieve convenient swallowing, reduce the size of the dosage form, and effectively control the release rate of modified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

1) Production of Inner Portion

[0106] 11.71% w / w of pravastatin sodium is mixed with 52.62% w / w of lactose monohydrate and 22.22% w / w starch and the mixture is granulated in a binder of 2.22 v povidone in water and then dried. The granules are sieved and mixed with 1.11% w / w magnesium stearate, 9.0 g sodium starch glycolate, 0.11% w / w lake of sunset yellow. This mixture is compressed to 90 mg weight tablets having a diameter of 6.35 mm

2) Production of Outer Portion

[0107] A) Micro matrix particles—90.91% w / w of niacin is mixed with 9.09% w / w of Eudragit RSPO (Ammonio Methacrylate Copolymer type B USP) and the mixture is granulated with a solvent mixture of acetone and methylene chloride and then dried. The granules are sized.

[0108] B) Coating of Micro matrix particles—85.84% w / w of micro matrix particles is charged in fluidized bed processor. 13.61% w / w of hydrogenated castor oil is dissolved in acetone and this coating solution is sprayed to coat the micro matrix particles. The...

example 2

1) Production of Inner Portion

[0114] 38.47% w / w of lamotrigine is mixed with 2.71% w / w of crosspovidone and 0.18% w / w colloidal silicon dioxide and the mixture is granulated in a binder of 0.71% w / w povidone in water and then dried. The granules are sieved and mixed with 28.70% w / w of Mannitol (Pearlitol SD 200®), 12.31% w / w of crosspovidone, 2.31% w / w of magnesium stearate, 6.15% w / w aspartame, 2.31% w / w talc, 5.0% w / w flavour and 1.15% w / w of colloidal silicon dioxide. This mixture is compressed to 65 mg weight tablets having a diameter of 5.55 mm.

2) Production of Outer Portion

[0115] A) Micro matrix particles—90.91% w / w of sodium valproate is mixed with 9.09% w / w of Eudragit RSPO (Ammonio Methacrylate Copolymer type B USP) and the mixture is granulated with a solvent mixture of acetone and methylene chloride and then dried. The granules are sized.

[0116] B) Coating of Micro matrix particles—85.84% w / w of micro matrix particles is charged in fluidized bed processor. 13.61% w / w...

example 3

1) Production of Inner Portion

Same for Example 1

2) Production of Outer Portion

[0122] 77.76% w / w of niacin is mixed with 7.78% w / w of Eudragit RSPO (Ammonio Methacrylate Copolymer type B USP) and the mixture is granulated with a solvent mixture of acetone and methylene chloride and then dried. The granules are sized and mixed with 13.61% w / w of hydrogenated castor oil and 0.86% w / w of magnesium stearate.

2) Compression of Tablets

Tablet (A)—Same as for Example 1

Tablet (B)—Same as for Example 1

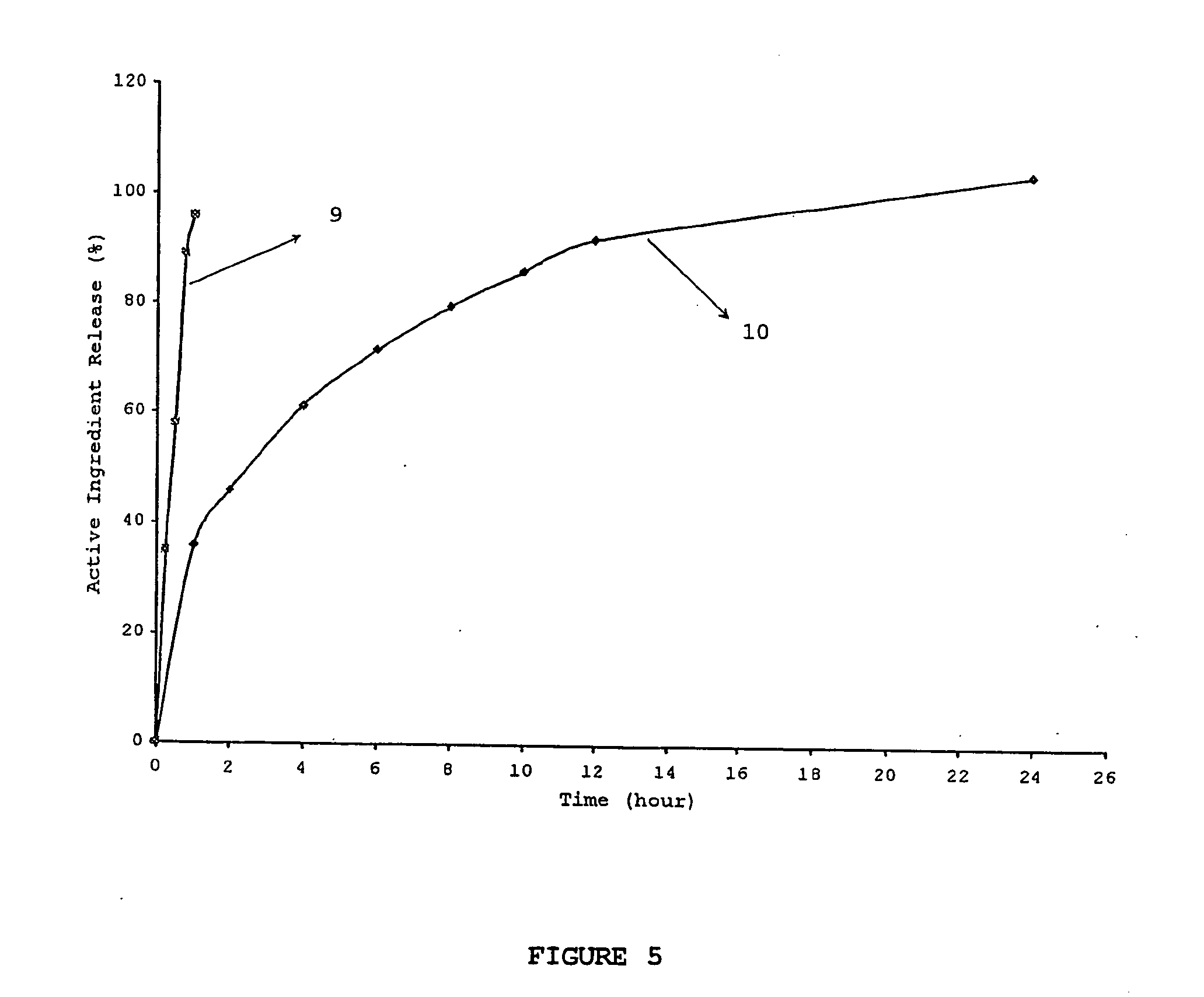

[0123] The dissolution rate of the novel dosage form was determined (Table 5 and 6)

TABLE 5Dissolution profile of tablet (A)NiacinPravastatin sodiumTime (hour)% ReleasedTime (min)% Released130.14575.9243.66080.9461.6674.1883.91092.11299.424102.6

[0124]

TABLE 6Dissolution profile of tablet (B)NiacinPravastatin sodiumTime (hour)% ReleasedTime (min)% Released129.94589.6236.36090.0452.8663.4873.51077.81284.52490.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com