Melencion shear wall system

a shear wall and shear wall technology, applied in the field of shear walls, can solve the problems of mold growth, mold sporolation in wetted areas, and fungi to die due to viability exhaustion, and achieve the effect of increasing the ventilation of the shear wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

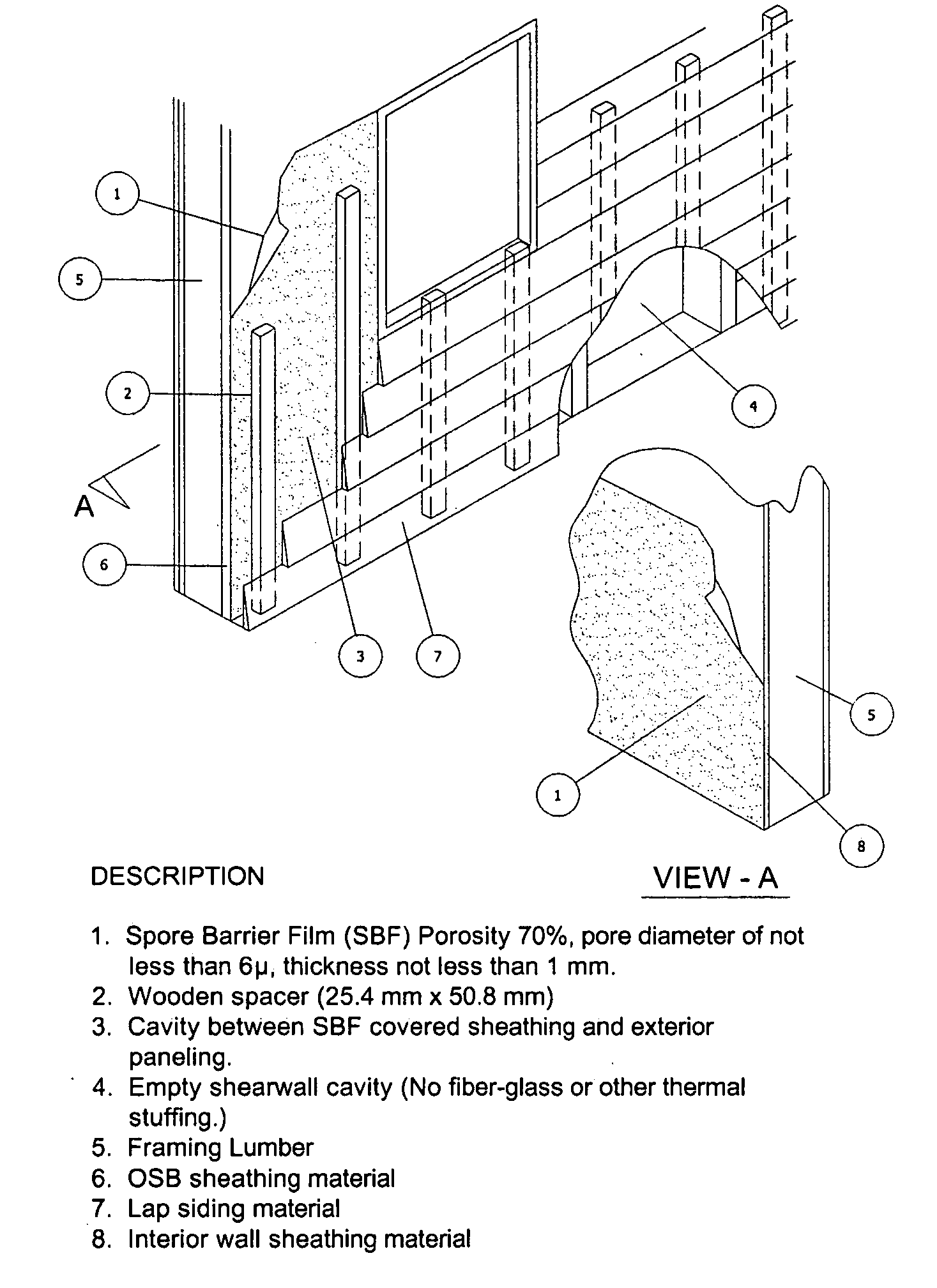

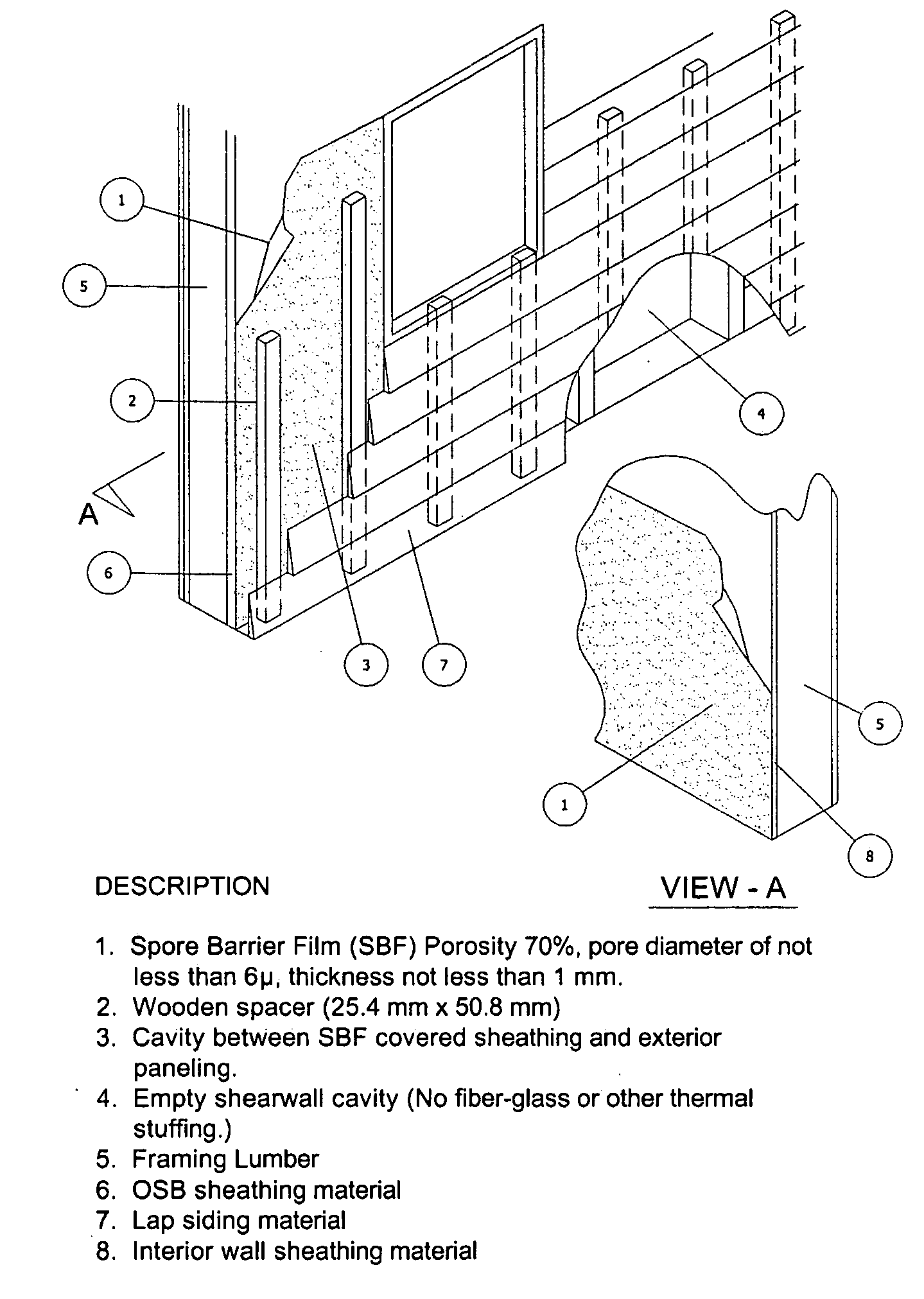

[0034] The Melencion Shear Wall System (MSWS) is a new system of shear wall construction based on the Melencion Theory On Mold-Decay Fungi Interactions In A Contained Environment that assures great improvement of shear wall durability to at least a minimum of 100 years or better. It is based on the observation on how decay fungi and mold interacts in a confined portion of the shear wall, provided that efficient aeration of the confined area is maintained with the use of 25.4 mm (1″) spacers over the sheathing material (as opposed to no spacers at all of the current shear wall construction code) and the removal of any fibro-thermal insulators often stuffed in the shear wall cavities in the current shear wall designs. The entry of new decay spores into the shear wall system is prevented by the use of a spore barrier film (70% porosity, not less than 6 micron pore diameter, and not less than 1 mm thick) over the sheathing material, the gypsum board and the side ends of the framing lumb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com