Diffractive optical element and bidirectional optical communication module using the same

a technology of optical communication module and optical element, applied in the direction of optics, instruments, optical light guides, etc., can solve the problems of reducing module performance and poor signal receiving accuracy, and achieve the effect of increasing diffraction efficiency, reducing the size of the optical communication module, and high module performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

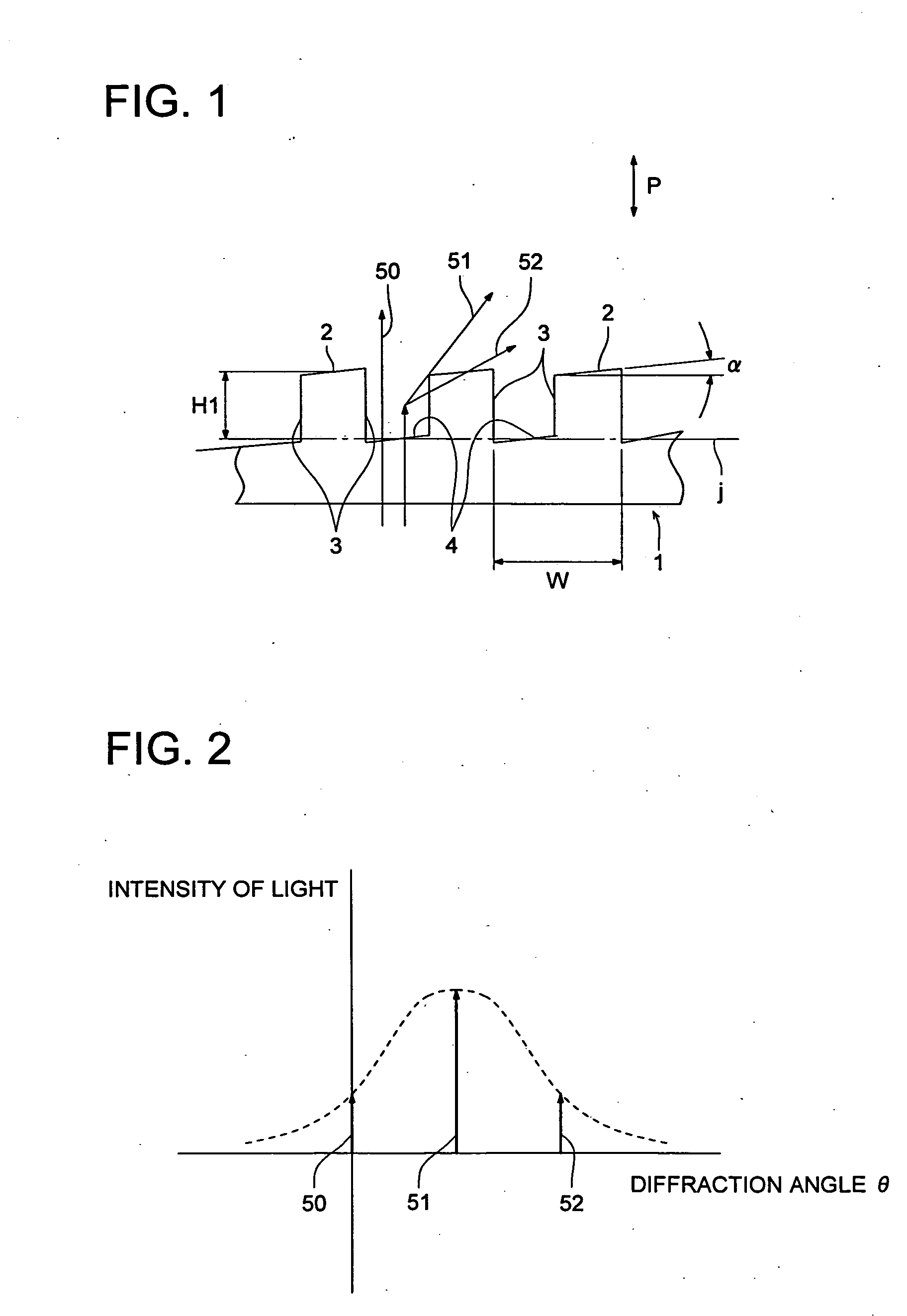

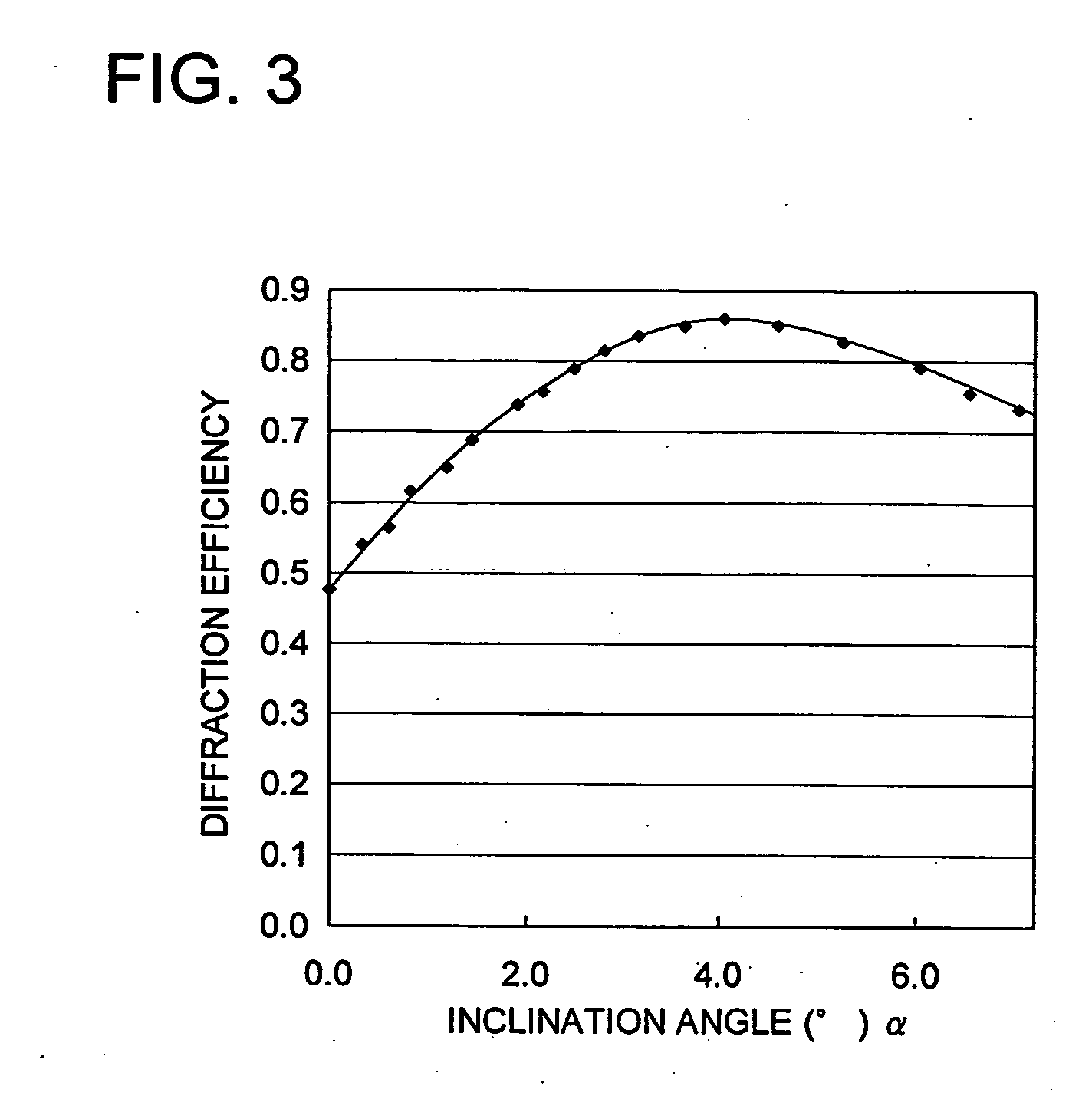

[0035]FIG. 1 is a partial side view showing main parts of the diffractive optical element according to the first embodiment. FIG. 2 is a view generally showing the intensity of light of each of the 0-order diffracted light beam, +1-order diffracted light beam, and +2-order diffracted light beam.

[0036] As shown in FIG. 1, the diffractive optical element according to the first embodiment is composed of the diffraction grating of the concave and convex shape by which different wavelengths are demultiplexed. The diffraction grating is formed into a shape whose same shape in which the diffraction surface top part 2 on the convex side and the diffraction surface bottom part 4 on the concave side repeat through the rising surface part 3 along the optical axis direction P is continued. That is, the diffraction grating is formed into a structure of the binary shape of so-called 2-level. The diffractive optical element 1 is composed of the optical material such as the gla...

second embodiment

The Second Embodiment

[0047]FIG. 4 is a partial side view showing main parts of the diffractive optical element according to the second embodiment. FIG. 5 is a partial side view showing main parts of another diffractive optical element according to the second embodiment.

[0048] As shown in FIG. 4 and FIG. 5, the diffractive optical elements 5, 5′ according to the second embodiment are reflection type in which the incident light beam is reflected, and is structured by the concave and convex shape diffraction grating by which the different wavelengths are demultiplexed, and the diffraction grating is formed into the same shape in which the diffraction surface top part 6 on the convex side and the diffraction surface bottom part 8 are repeated through the rising surface part 7 along the optical axis direction P. The diffraction surface grating side is formed into a reflection surface 9 formed of the high reflective surface onto which, for example, metals such as Ag, Al, Au, are evaporat...

third embodiment

The Third Embodiment

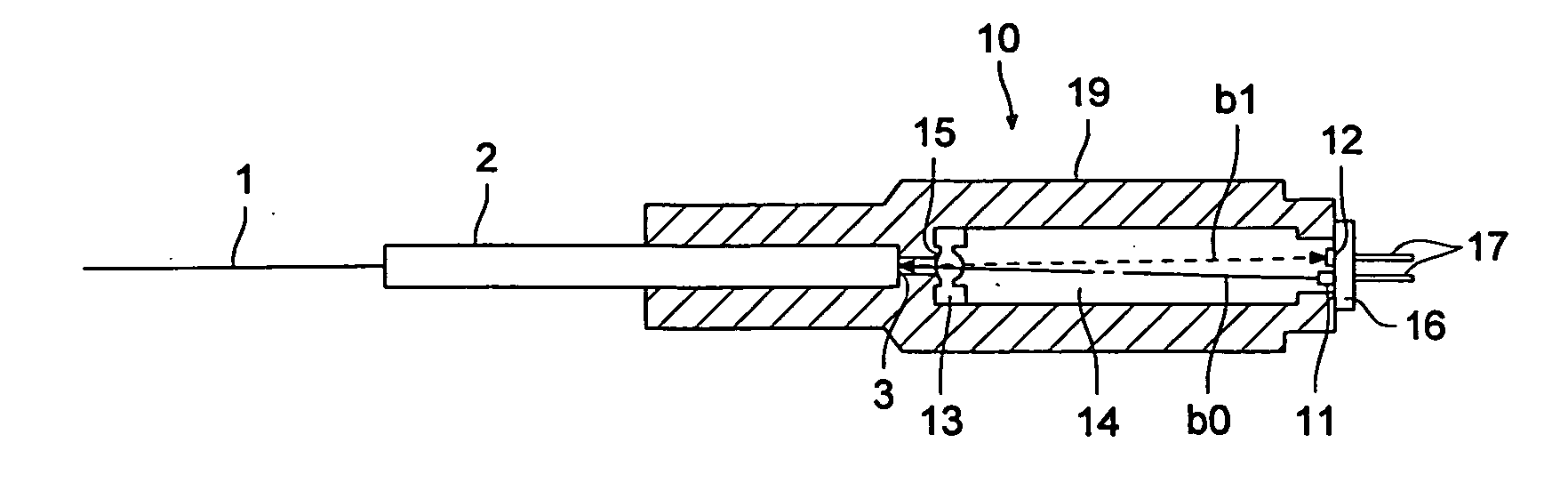

[0056]FIG. 6(a) is a main part sectional view in the longitudinal direction of the optical communication module according to the third embodiment. FIG. 6(b) is an enlarged plan view showing the diffraction grating formed on the surface of a combination lens 13 in FIG. 6(a). FIG. 6(c) is a schematic sectional view in which the diffraction grating formed on the surface of a combination lens 13 is cut in C-C direction in FIG. 6(b), and its section is enlarged.

[0057] As shown in FIG. 6(a), the bidirectional optical communication module 10 is provided with: in a long and narrow almost cylindrical casing 10, the light emitting element 11; the light receiving element 12; and the combination lens 13 as the optical device. The light emitting element 11 and the light receiving element 12 are provided common substrate 16, and fixed to the casing together with the substrate 16. Further, a plurality of connection pins protruded outside from the substrate 16 are electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com