Passive thermoacoustic cooling apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

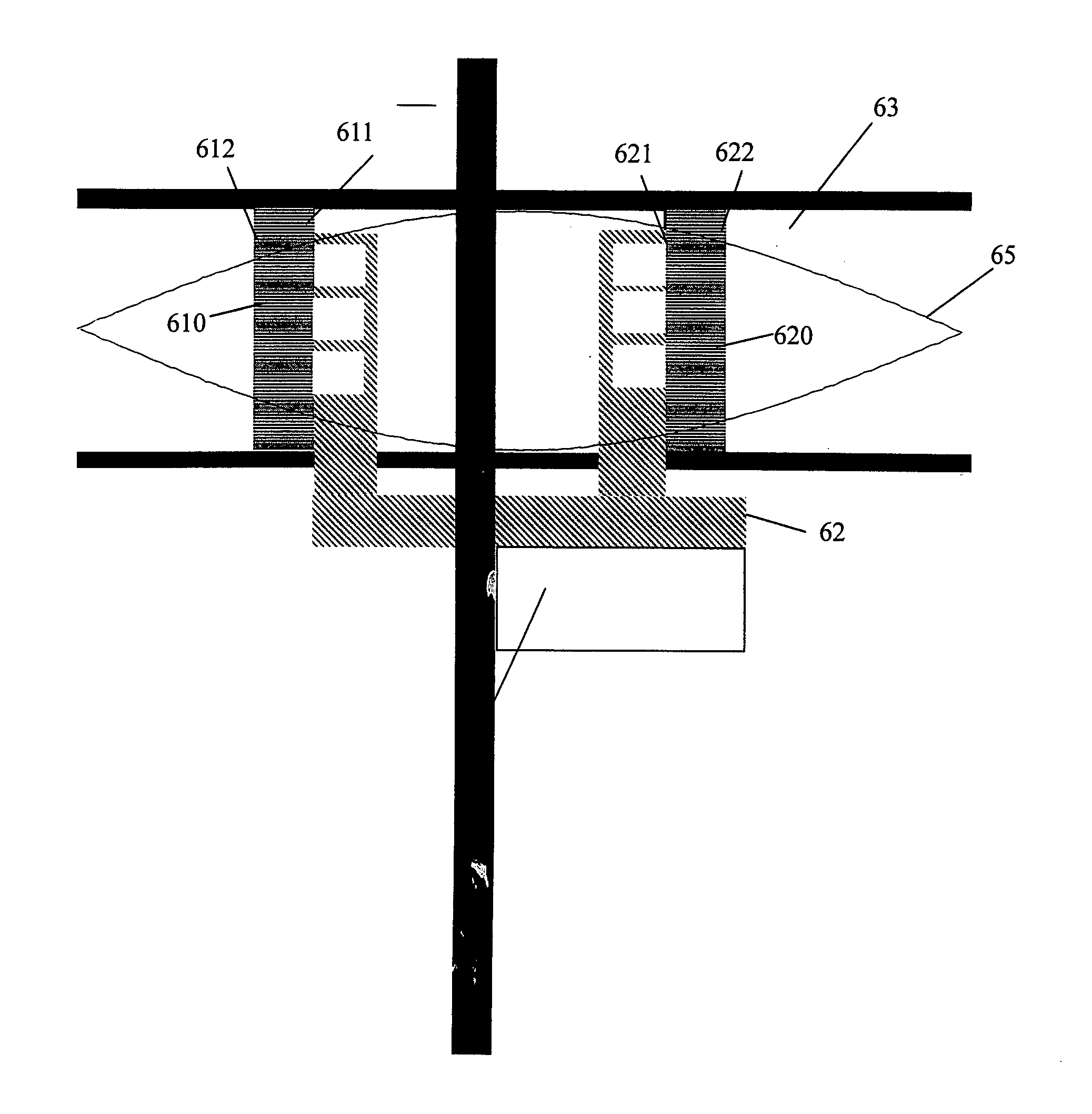

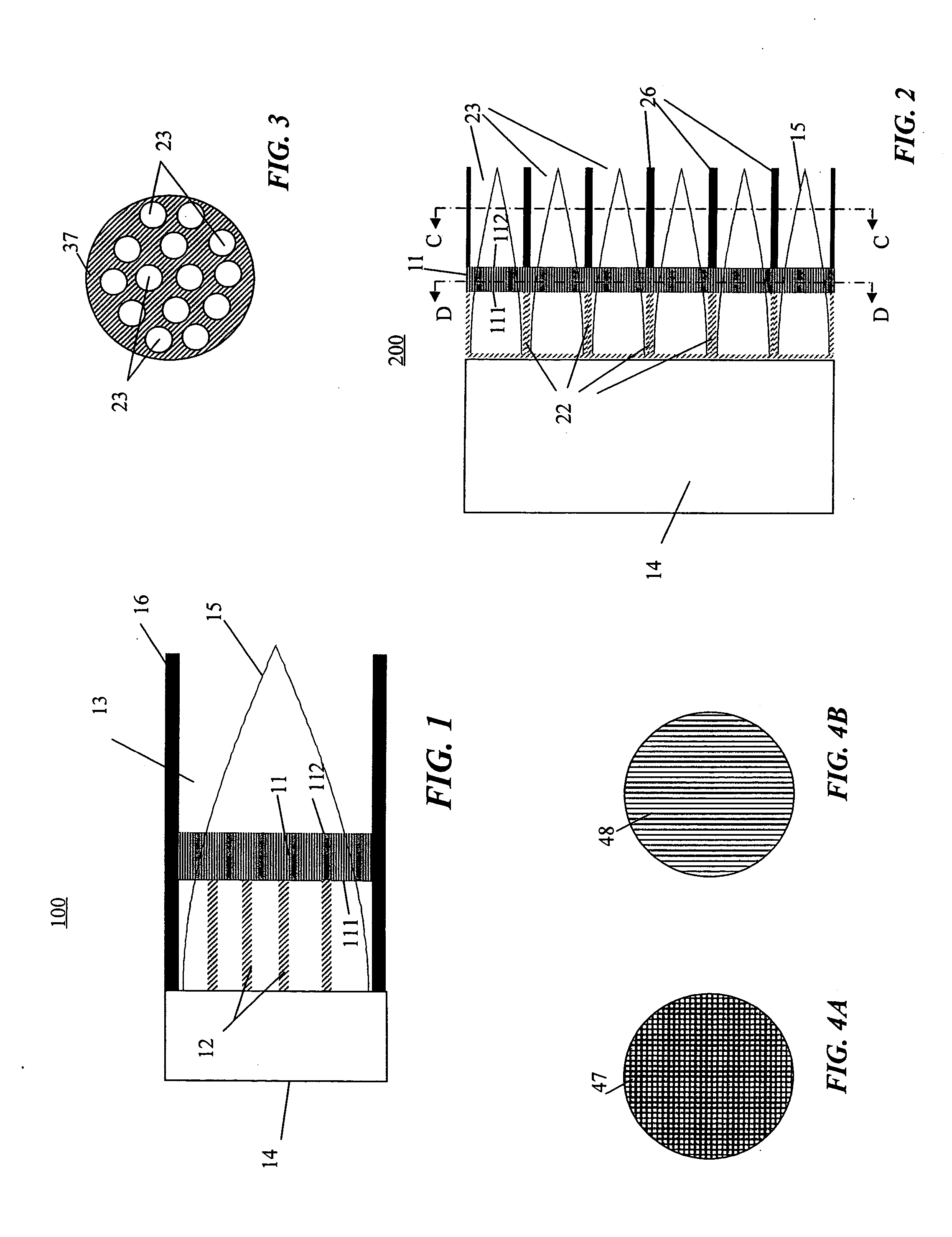

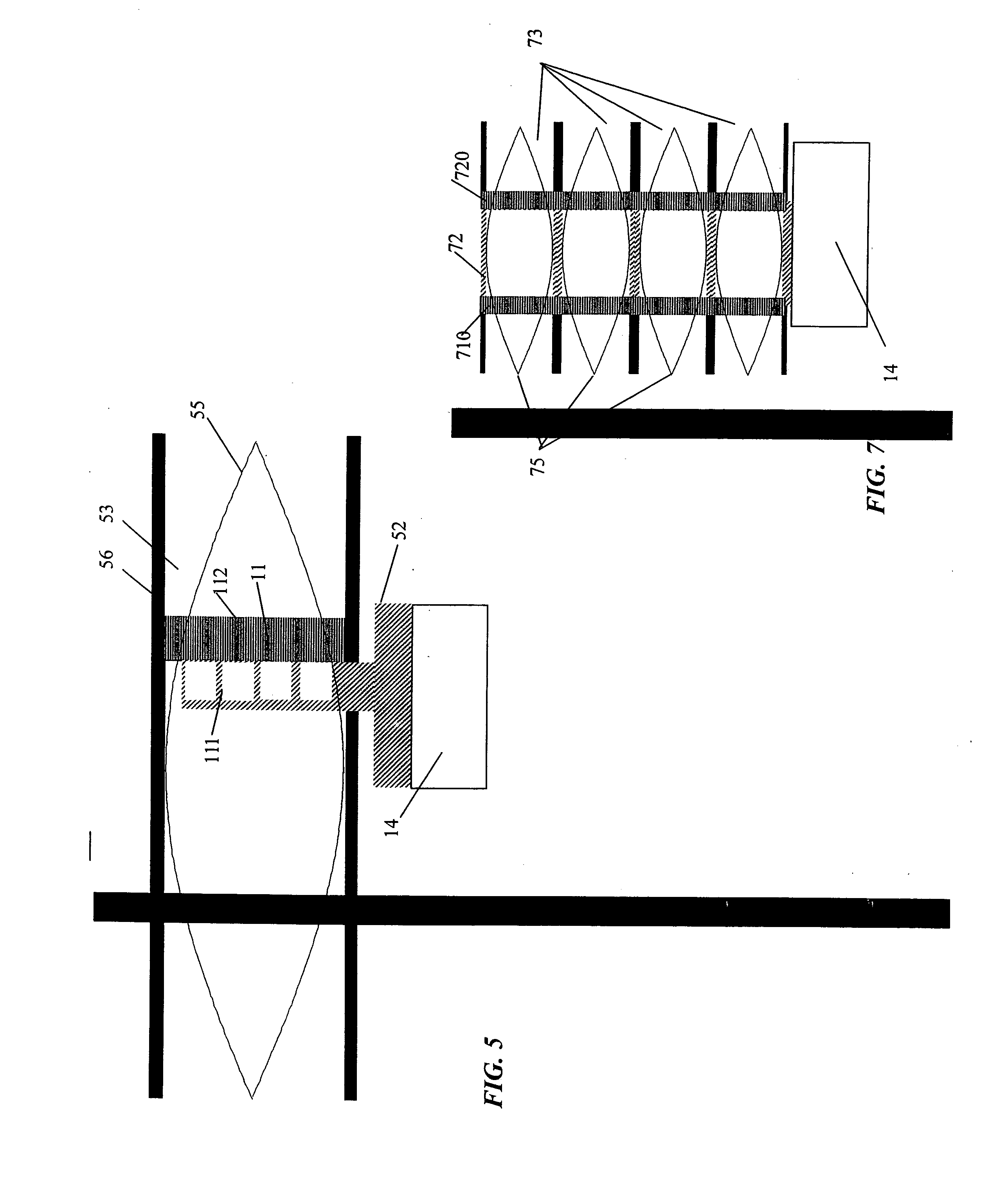

[0018] A preferred embodiment of the thermoacoustic heat dissipation apparatus in accordance with the present invention is schematically illustrated in FIG. 1. The thermoacoustic heat dissipation apparatus identified by 100 has a heat conduction element 12 and a temperature difference element 11 generally enclosed in a resonance cavity 13. Standing waves generated as a result of thermoacoustic effect by the resonance cavity 13 appear within the space generally defined by the cavity casing 16. One end of the generally elongated resonance cavity 13 as illustrated in the drawing is closed by a heat source 14 to be cooled. The other end of the cavity 13 remains open.

[0019] Longitudinal length of the resonance cavity 13 can be selected to be a quarter of the acoustic wavelength of the basic frequency at which resonance tends to occur. Air pressure distribution for the standing wave in the resonance cavity most likely to appear is schematically shown in FIG. 1 as curve 15. Curve 15 repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com