Gas Fireplace

a gas fireplace and gas technology, applied in the field of gas fireplaces, can solve the problems of unsatisfactory heat gradient generation, uneven heating of the room, and considerable increase in noise pollution, and achieve the effects of reducing or at least substantially reducing the above mentioned drawbacks, optimum efficiency, and high yield and autonomy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

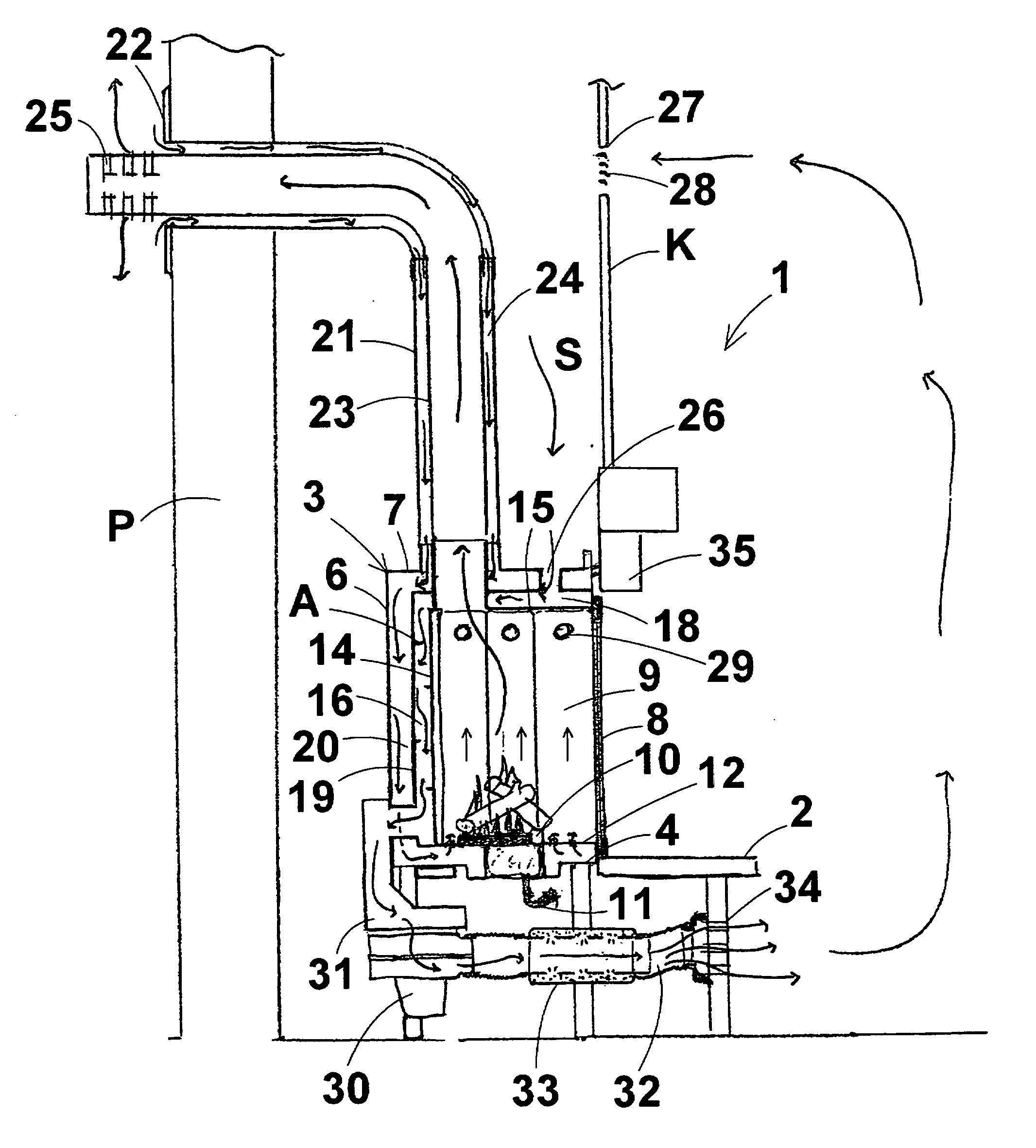

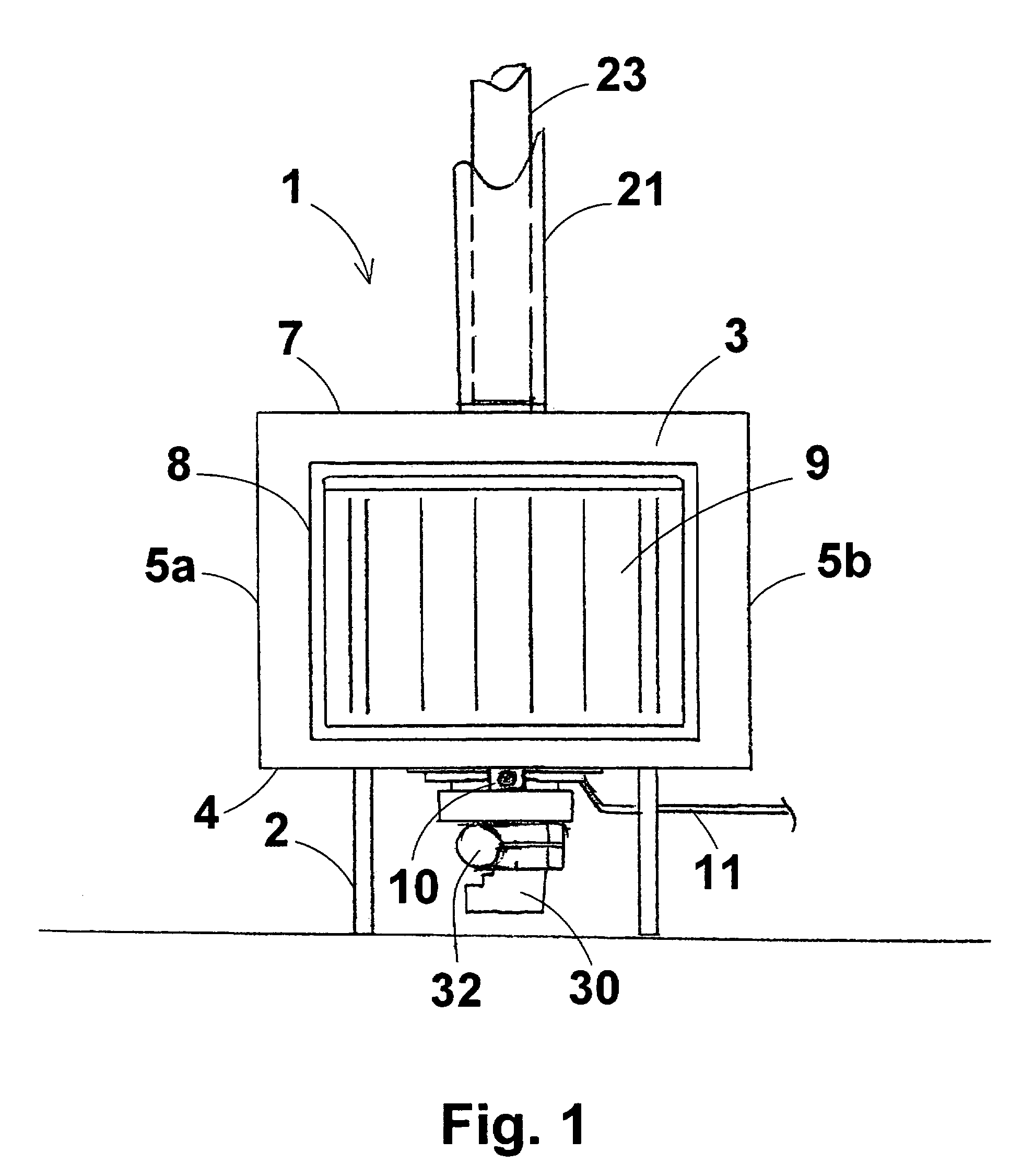

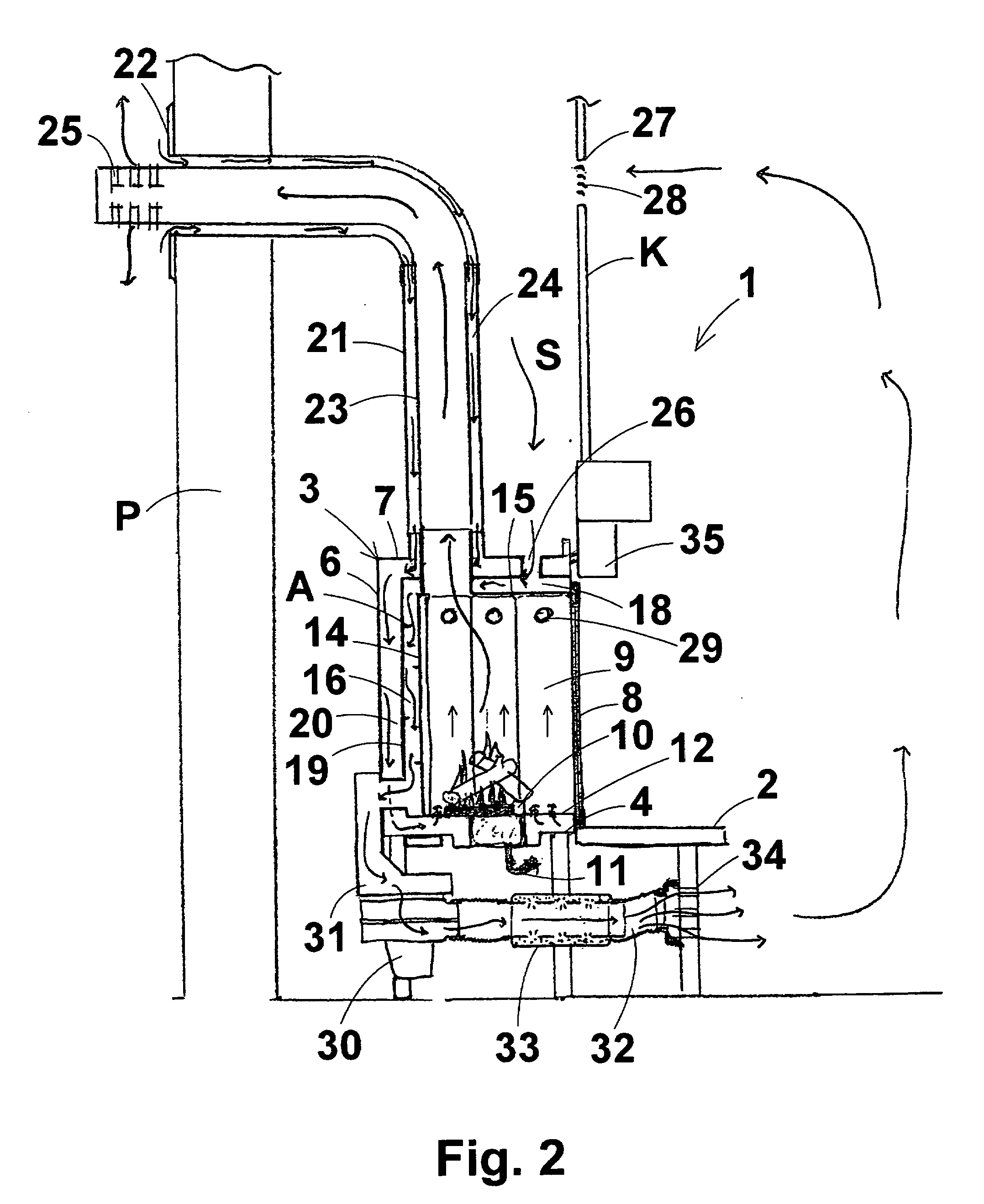

[0023] With reference to the above listed Figures, a gas fireplace according to the present invention, generally designed with reference numeral 1, comprises a support and housing frame including a base 2, preferably covered with lining members, e.g. made of marble or ceramic material, from which a substantially parallelepiped housing 3 rectangular in top view rises. The housing 3 delimits a closed inner space and comprises a lower or bottom wall 4, two side walls 5a, 5b, a rear wall 6, an upper or ceiling wall 7, as well as a front door 8, preferably made of glass or, more preferably, ceramic glass, in order to ensure a good heat-tight arrangement.

[0024] The inner space of the housing 3 is subdivided into a number of adjacent chambers, as described below.

[0025] In the innest portion there is provided a combustion chamber 9, where a gas burner 10 is located, to which fuel gas can be fed through a feeding duct 11 in fluid communication with a suitable fuel gas source (not shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com