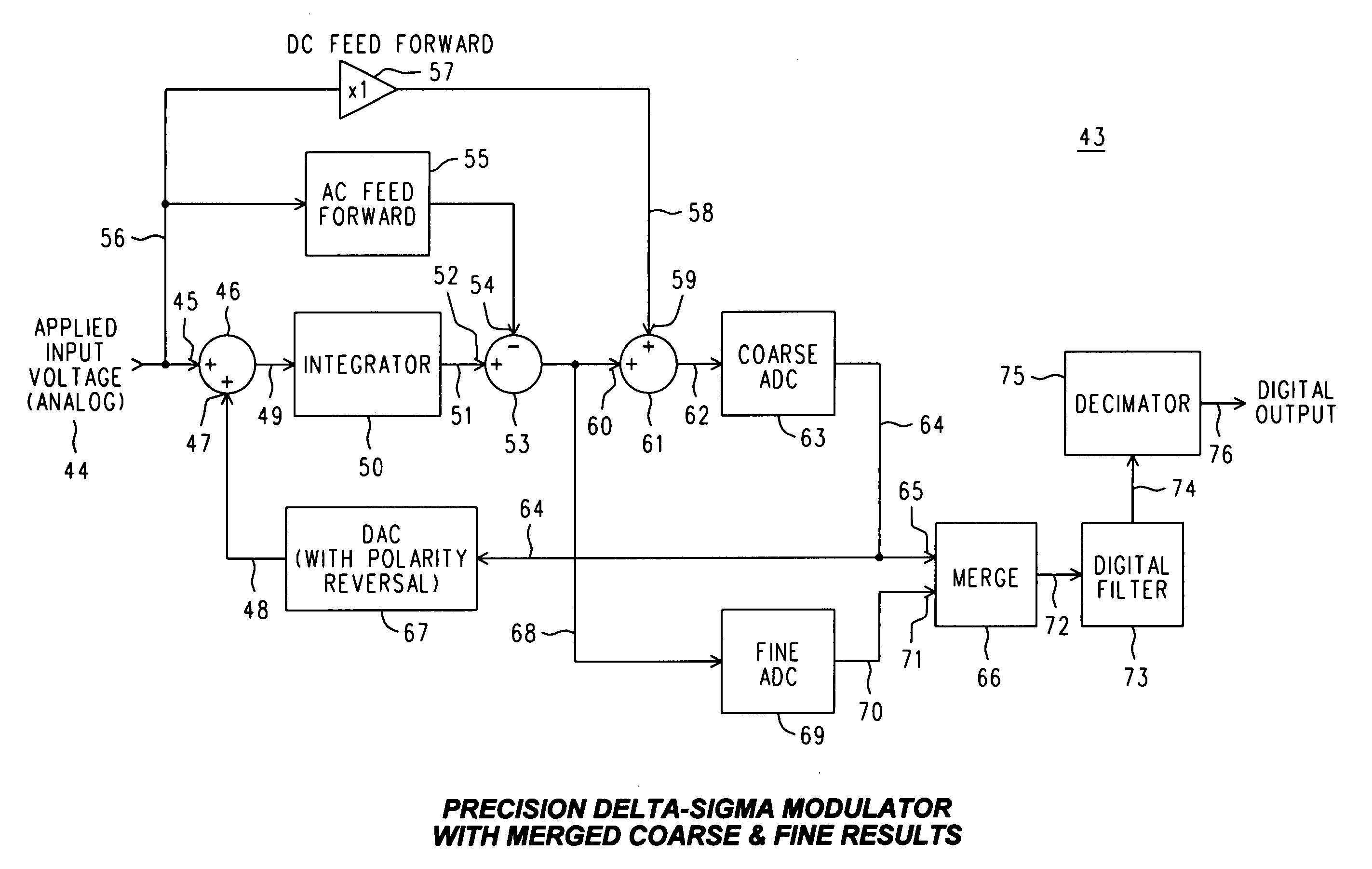

Precision low noise delta-sigma ADC with ac feed forward and merged coarse and fine results

a low noise, delta-sigma technology, applied in transmission systems, analogue/digital conversion, instruments, etc., can solve the problems of reducing the accuracy of delta-sigma converters, limiting the precision of capacitor integration techniques, and degrading loop performance, so as to achieve stable high-speed precision results and increase resolution. , the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

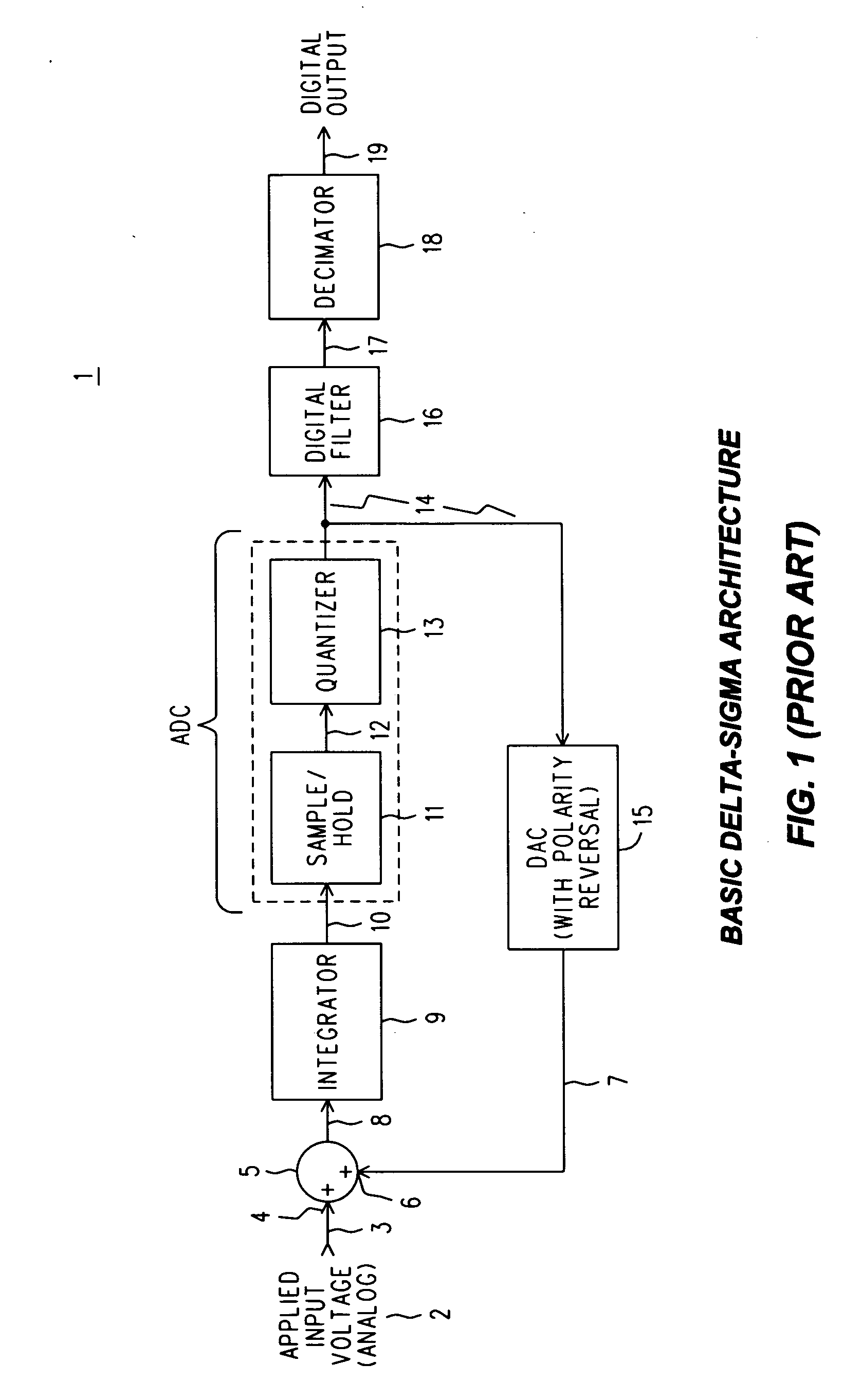

[0016] Refer now to FIG. 1, wherein is shown a simplified block diagram 1 of an early prior art delta-sigma arrangement for performing analog to digital conversion. An input voltage 2 is applied to an input conductor 3, from whence it is coupled to a first+(plus) input 4 of an analog voltage summing circuit 5. The input voltage applied to conductor 3 may be subjected to previous suitable signal conditioning (not shown) before it reaches the first+input 4, the purpose of which signal conditioning might be to attenuate the input by a known amount, limit dv / dt, or limit voltage excursions by clipping them when they exceed a certain magnitude, etc.

[0017] Also applied to the voltage summing circuit 5 at a second+terminal 6 is a feedback voltage 7, that approximates to a greater or lesser degree an opposite polarity replica of the applied input signal 2. Thus, the output 8 of the voltage summing circuit 5 is an error signal (difference) indicative of the manner in which the feedback volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com