Blistered rapid diagnostic test with incorporated moisture absorbent material

a technology of incorporated moisture and rapid diagnostic test, which is applied in the field of rapid diagnostic test with incorporated moisture absorbent material, can solve the problems of changing the characteristics and properties of the product, increasing the price, and difficult to guarantee the subsequent shelf life of the product contained therein, and achieves the effect of facilitating the grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

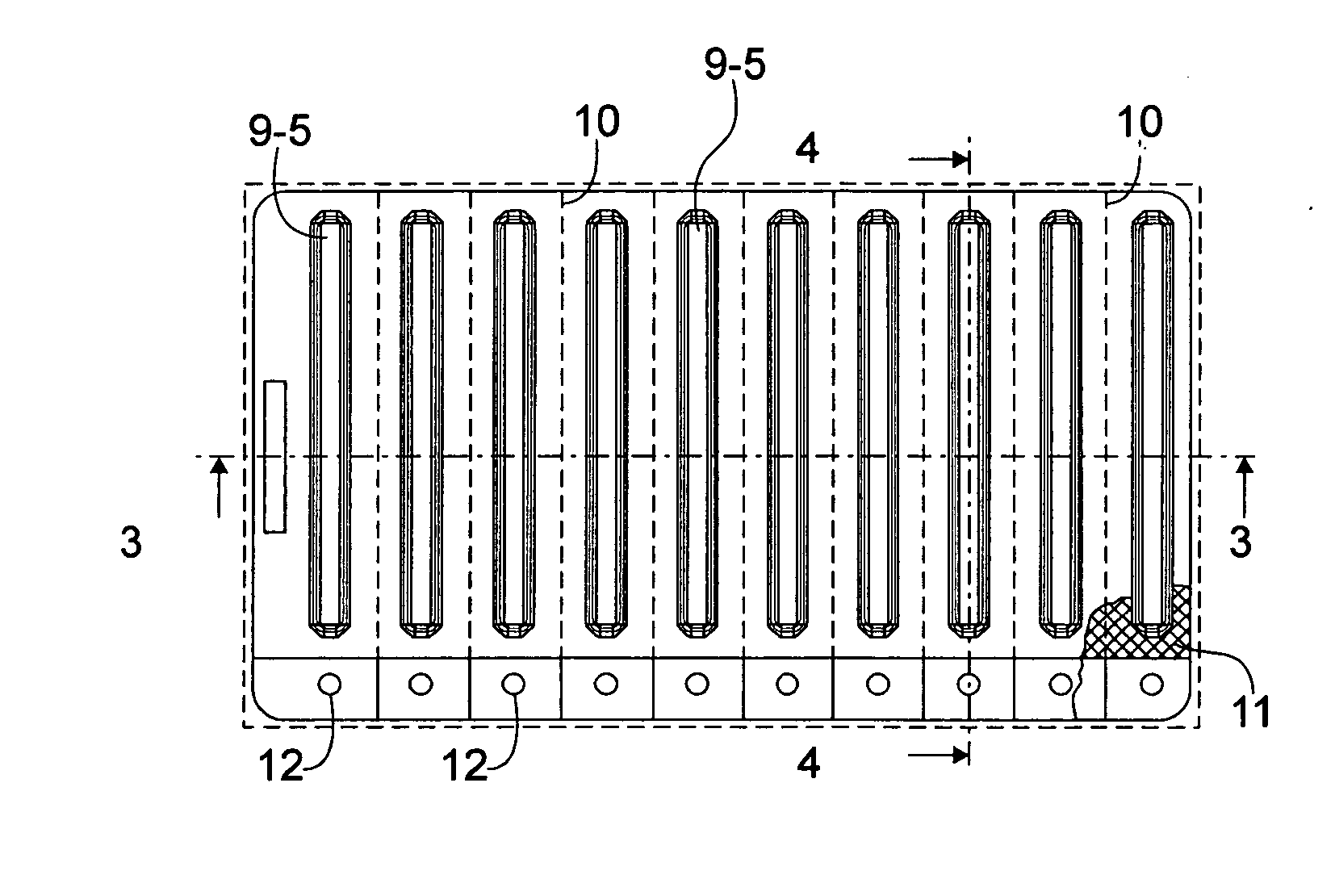

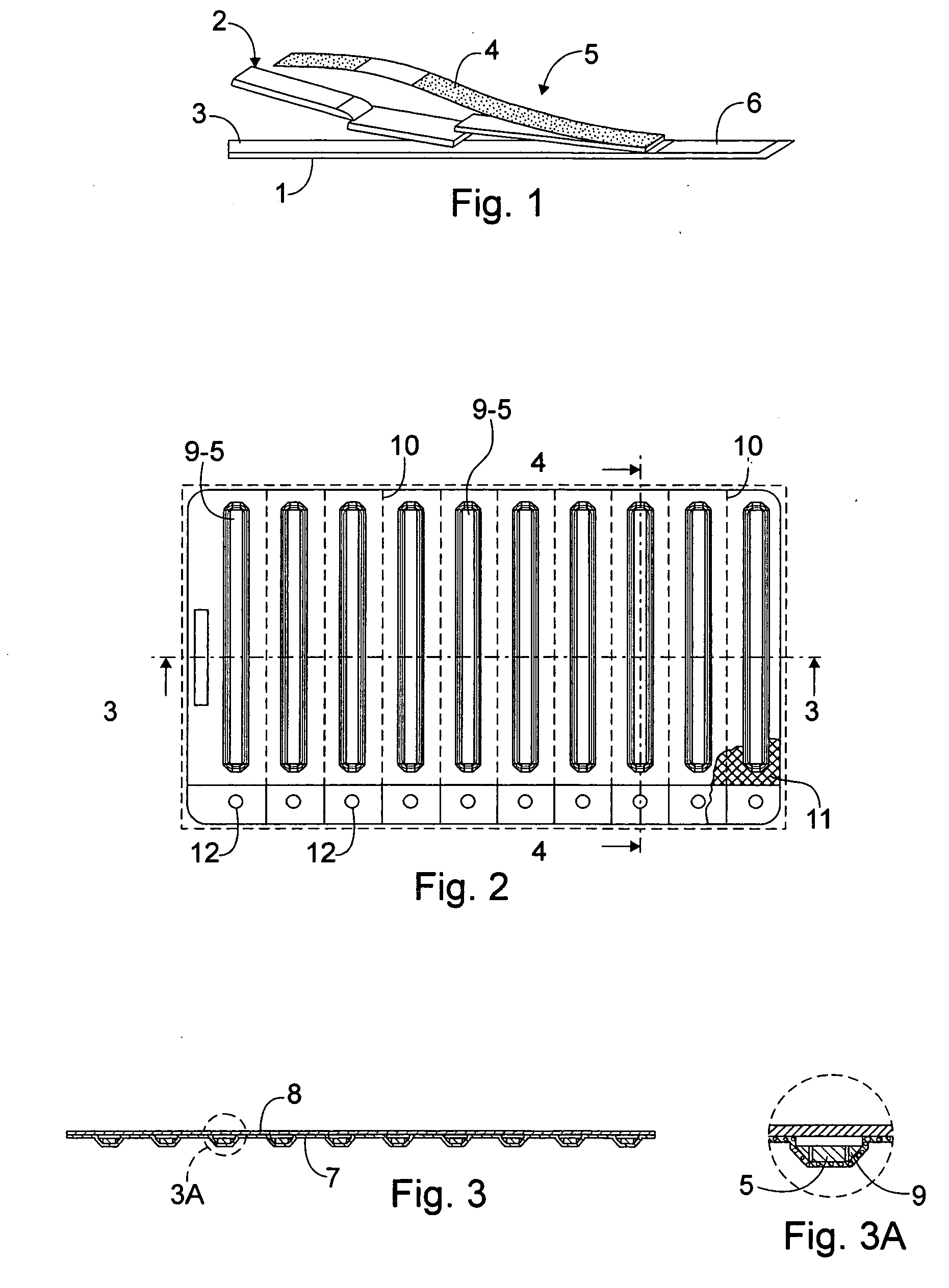

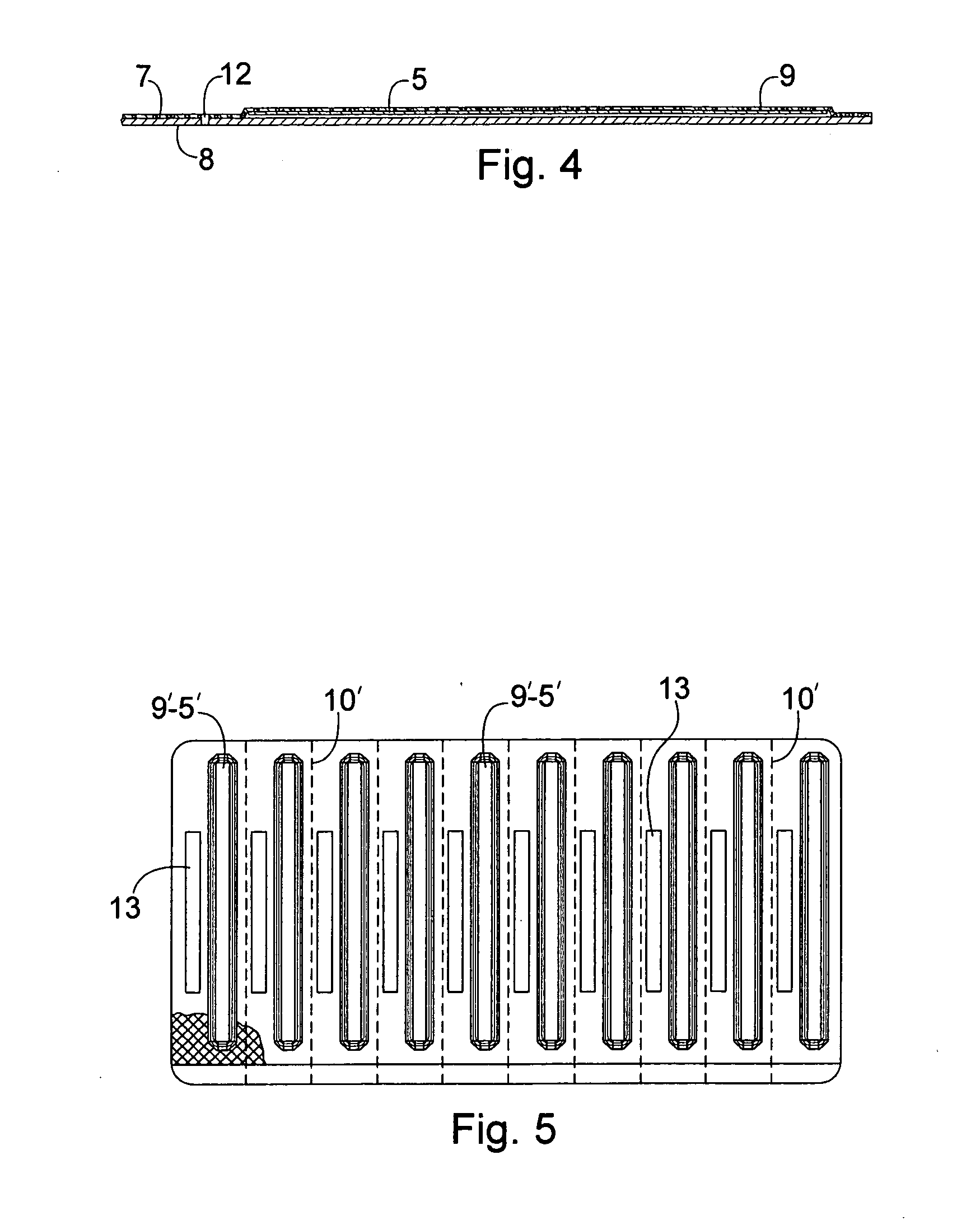

[0034] In light of the described figures, and more specifically FIG. 1, we can observe that the rapid diagnostic test in the form of a reactive strip represented therein is formed from a laminated plastic base (1), which gives it the rigidity necessary for its correct handling, a base which is joined to a structure (2) comprising the test, by means of a double-sided adhesive (3), adding one or more protective sheets (4) to the unit, which protect and prevent contamination of the structure (2) or test, thereby avoiding it from being damaged and possible errors from occurring in the test results.

[0035] The laminated plastic base (1) is the test element which incorporates the moisture absorbent material, which will be comprised of a combination of one or more polymers together with the drying agent responsible for absorbing the moisture.

[0036] As has been previously explained, the test elements (2) can be directly adhered to the base (1) or, as is shown in FIG. 1, by means of a doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com