Filter-tipped cigarette

a filter and cigarette technology, applied in the field of tobacco industry, can solve the problems of only reducing partially the amount of toxic and mutagenic compounds entering the smoker's body, smoking less attractive for smokers, and smoking less attractive, so as to improve the efficiency of tobacco smoke cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

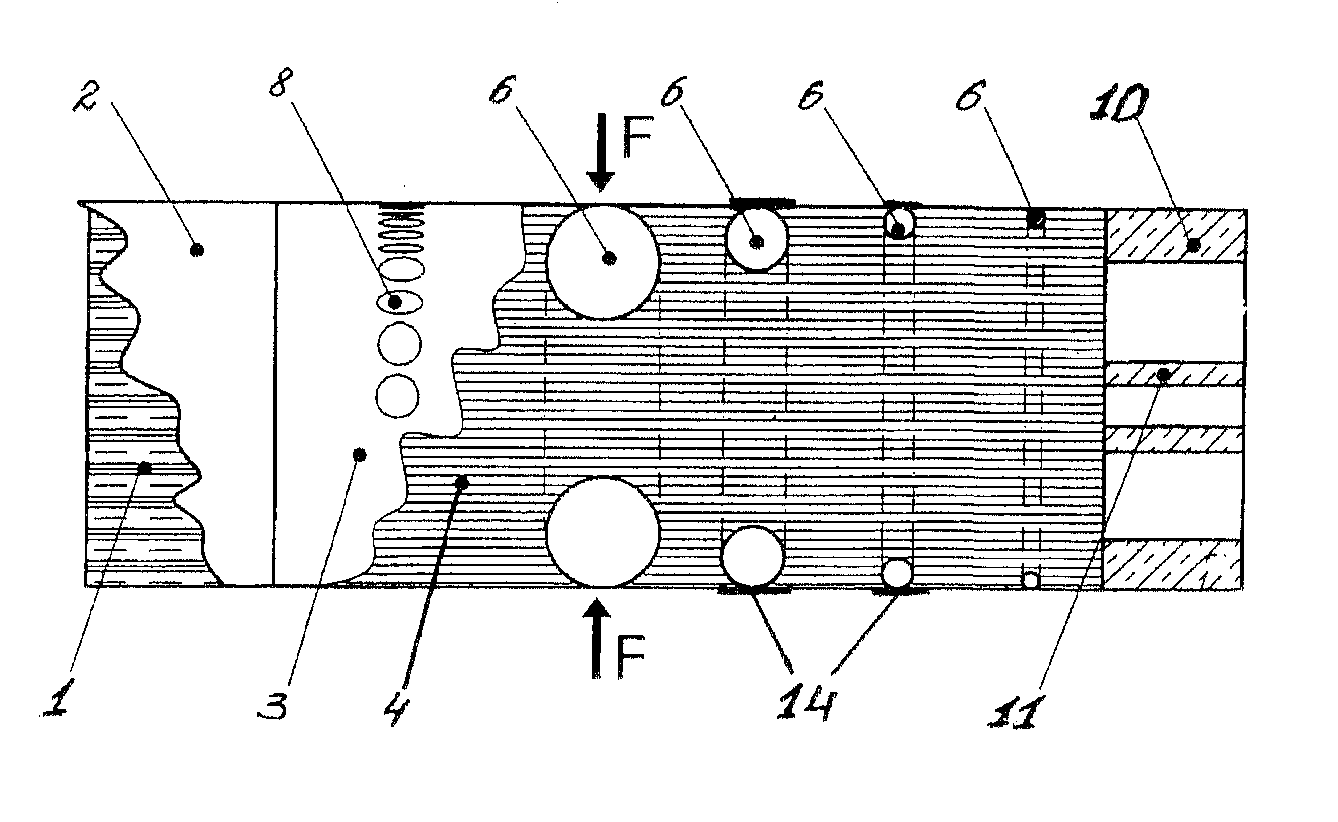

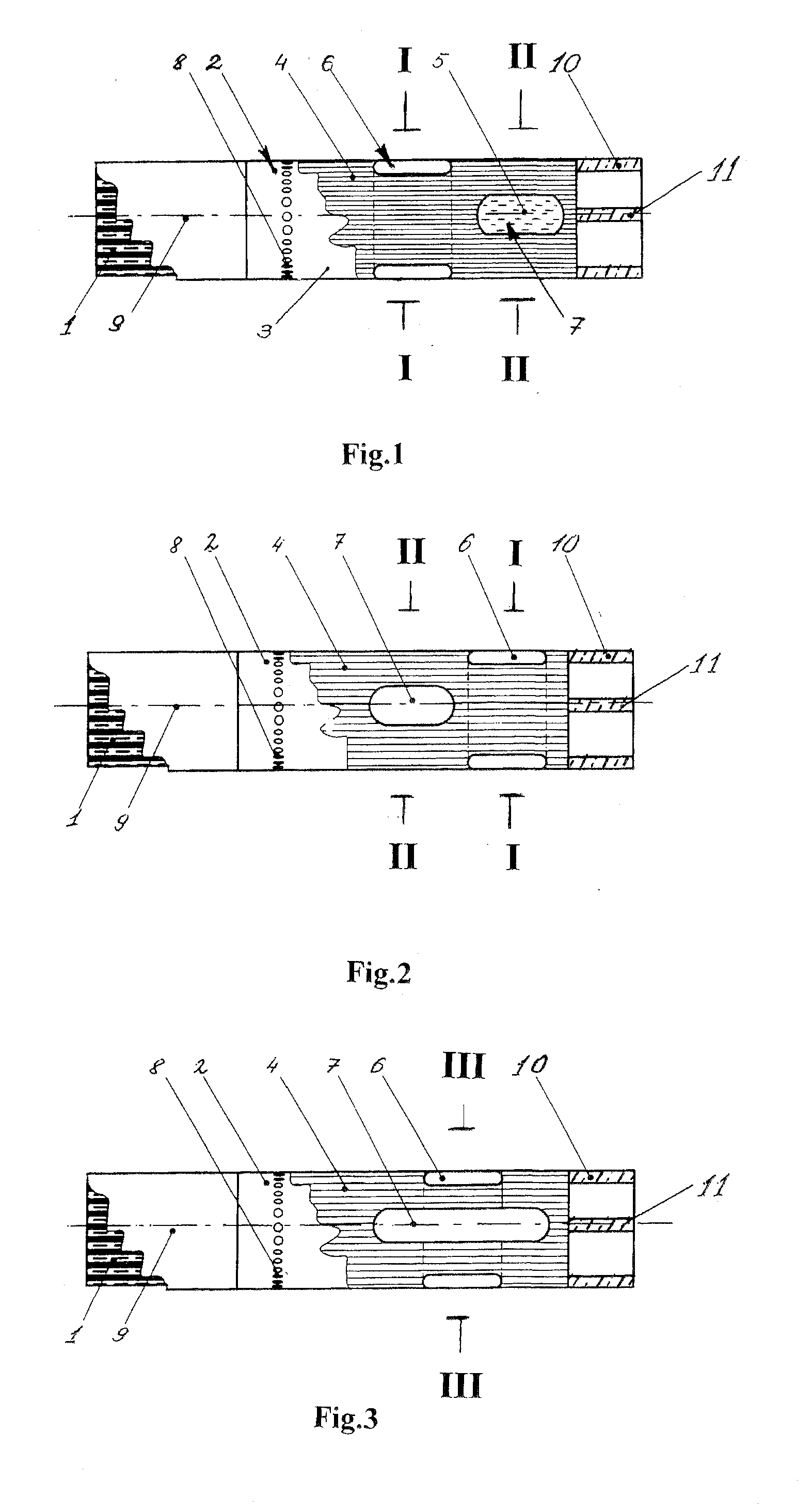

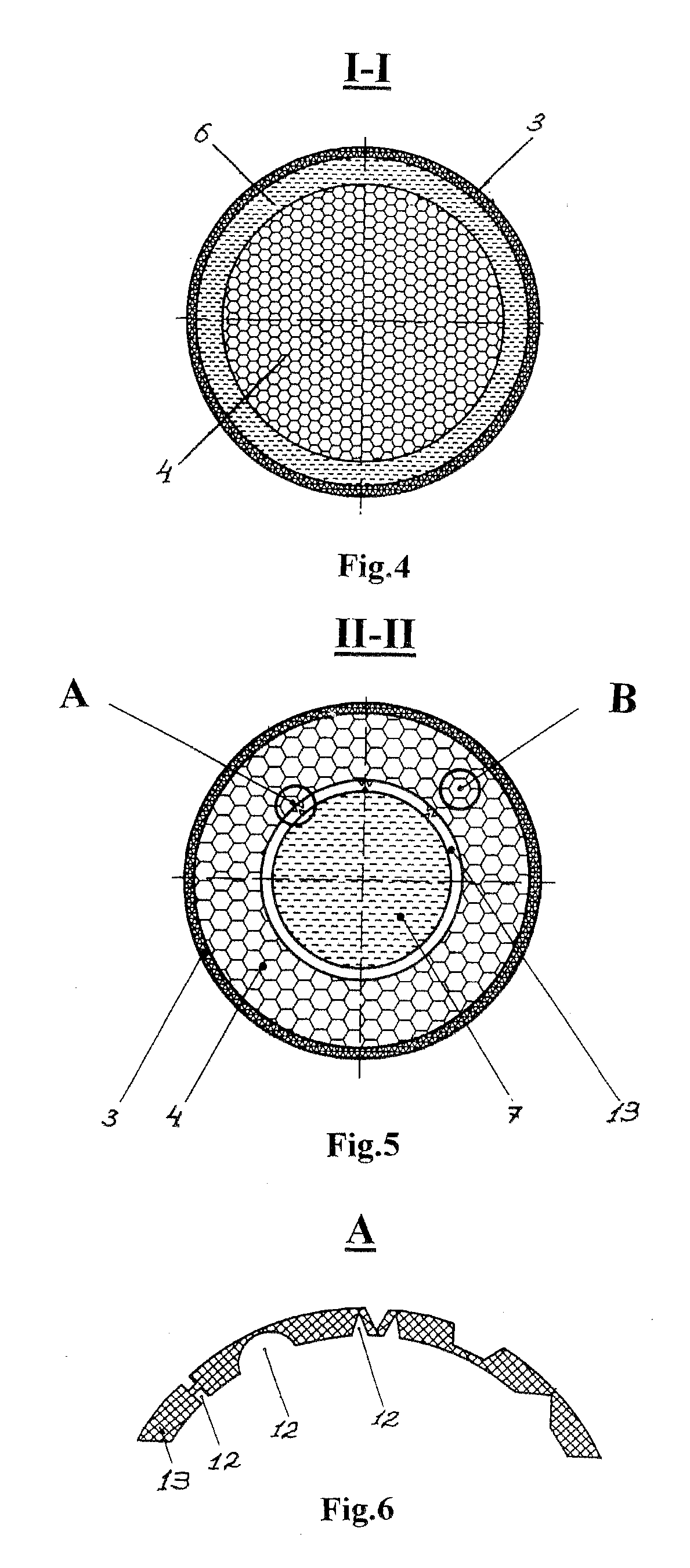

Method used

Image

Examples

example 1

[0097] Forty cigarettes were used manufactured according to ISO 3402 (cigarette weight 874±20 mg). Twenty cigarettes were kept as a reference batch, and two ampoule-type capsules in the form of a globe were put in each of the remaining twenty cigarettes. Thereafter, each cigarette was weighed again. Said first ampoule-type capsule had a casing made of aluminum foil, and said second ampoule-type capsule had silver foil casing. A double-sided notching was provided on the inner and the outer sides of both ampoule-type capsules. In said first capsule a rectangular notching was provided with the surface area of 1 mm 2, and a M-shaped notching was provided in said second capsule, with the surface area of 1.5 mm 2. A first filtering member in the thus modified filter amounted to about 29% of its initial volume as determined by individual weighing of the filtering material filaments removed by mechanical micromilling, with said filaments having the weight of 56 to 60 mg.

[0098] Then, a ciga...

example 2

[0103] Thirty cigarettes were used, ten of which were kept as a control batch.

[0104] Ten cigarettes of the first batch were brought to conformity with the inventive filter design shown in FIG. 1, and the remaining ten cigarettes of the second batch were brought to conformity with the filter design shown in FIG. 2.

[0105] Cigarettes of the first batch were provided with a tubular capsule containing 40 percent by volume of a liquid flavoring agent in the form of a 60% ethanol-based extract containing fennel oil, said capsule being mounted in the porous filtering member on the part of the filter end abutting on the tobacco core. An ampoule-type capsule containing 98 percent by volume of deionized water was placed in the porous filtering member on the part of the mouthpiece. A waterproof paper impregnated from the inside with a thin layer of paraffin refined wax was used as the filter casing.

[0106] Cigarettes of the second batch were provided with an ampoule-type capsule containing 98...

example 3

[0116] Seventy filter-tipped cigarettes were used, having the porous filtering member in the form of acetate fiber tow and provided with a plastic mouthpiece. Ten cigarettes of the said seventy cigarettes were kept as a control batch.

[0117] The ratio of 1:3 was established between tubular and ampoule-type capsules. The remaining sixty cigarettes were divided into the first batch (30 cigarettes) and the second batch (30 cigarettes).

[0118] Cigarettes of the first batch were provided with a tubular capsule containing a flavoring agent in the form of a gas-vapor composition comprising 40% of eucalyptus ester in freon gas, said capsule being mounted in the porous filtering member on the part of the filter end abutting on the tobacco core. Then, an axial recess was made in the porous filtering member on the mouthpiece part, wherein three ampoule-type capsules were placed one after another. The relative volume change between said capsules was adjusted based on the following ratio: 70%: 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com