Microcellular foam of thermoplastic resin prepared with die having improved cooling property and method for preparing the same

a thermoplastic resin and microcellular technology, applied in the field of microcellular foam of thermoplastic resin, can solve the problems of poor mechanical strength and toughness of foams, and all the products produced from the above-mentioned patents have mechanical properties that are poorer than those of non-foamed counterparts, and achieve the effect of low specific gravity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

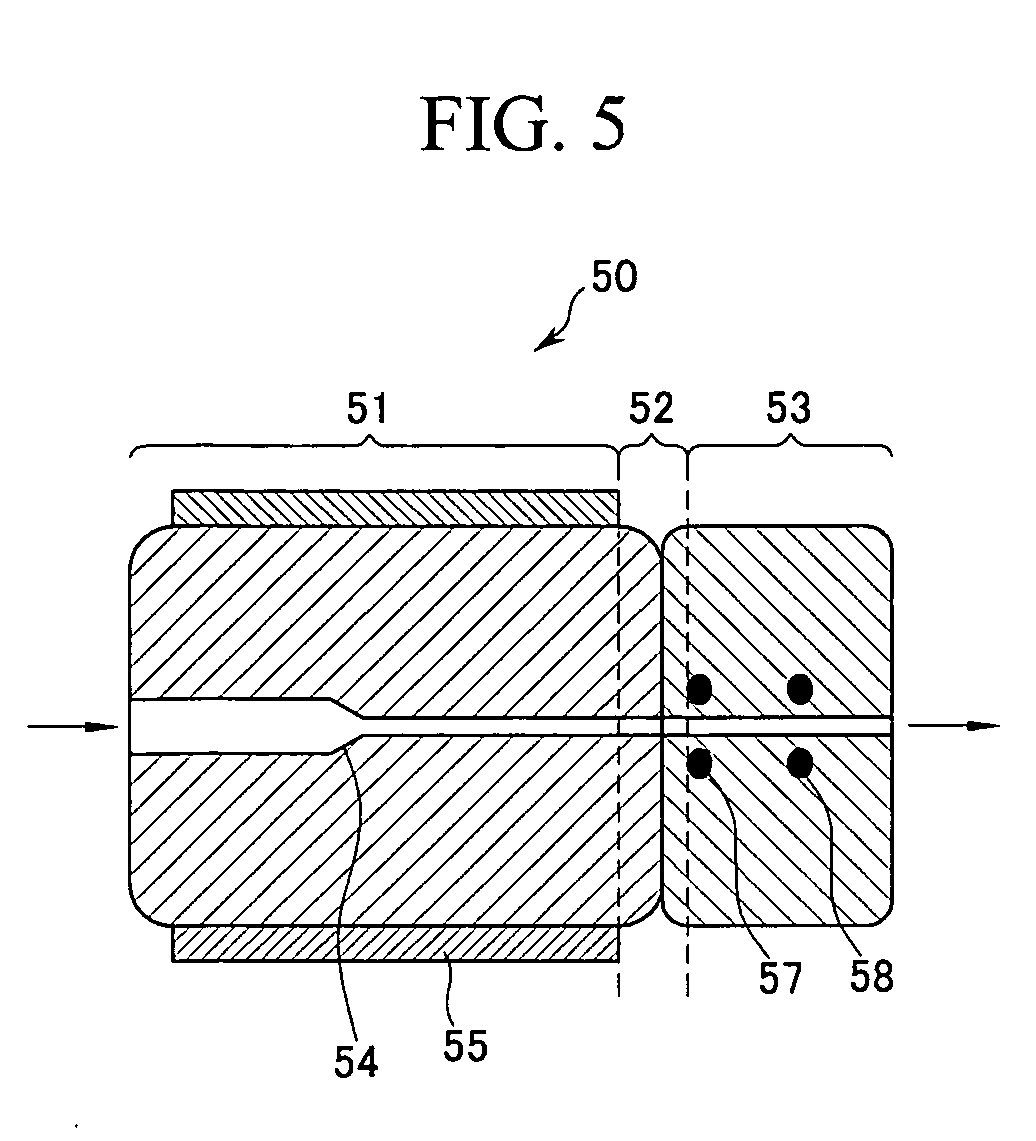

[0061] An extrusion apparatus 30 was prepared by attaching an extrusion die 34 that is capable of temperature control, which comprises a pressure drop region 31, a temperature change region 32, and a cooling region 33, and an adapter 35, to a twin screw extruder 36 (Göttfert Extrusiometer 350), as in FIG. 3. The lengths of the pressure drop region 31, the temperature change region 32, and the cooling region 33 of the extrusion die were 125 mm, 27 mm, and 40 mm, respectively.

[0062] 98 parts by weight of a rigid polyvinyl chloride (PVC) compound (LG Chem) used for interior / exterior housing and construction materials was added to the extruder. After the PVC was completely plasticized, 2 parts by weight of nitrogen was added to the barrel 4 of the extruder using a high-pressure pump. The resultant single-phase mixture was foamed to obtain a microcellular foam sheet 2 mm thick and 100 mm wide.

[0063] The temperature of the barrel 1 was maintained at 190° C., that of barrels 2 to 4 at 18...

examples 2 and 3

[0065] A microcellular foam sheet was prepared in the same manner as in Example 1 except that the temperatures of the pressure drop region, the temperature change region, and the cooling region were changed as given in Table 1.

example 4

[0066] A microcellular foam sheet was prepared in the same manner as in Example 1 except that the temperatures of the pressure drop region, the temperature change region, and the cooling region were changed as given in Table 1, and a die that produces a 1 mm-thick sheet was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com