Ambulatory infusion membrane pump

a membrane pump and ambulatory technology, applied in the direction of positive displacement liquid engine, process and machine control, instruments, etc., can solve the problems of high cost of hospitals, complicated check valve arrangement of cassette, and many of these pumps are very sophisticated and sometimes very complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

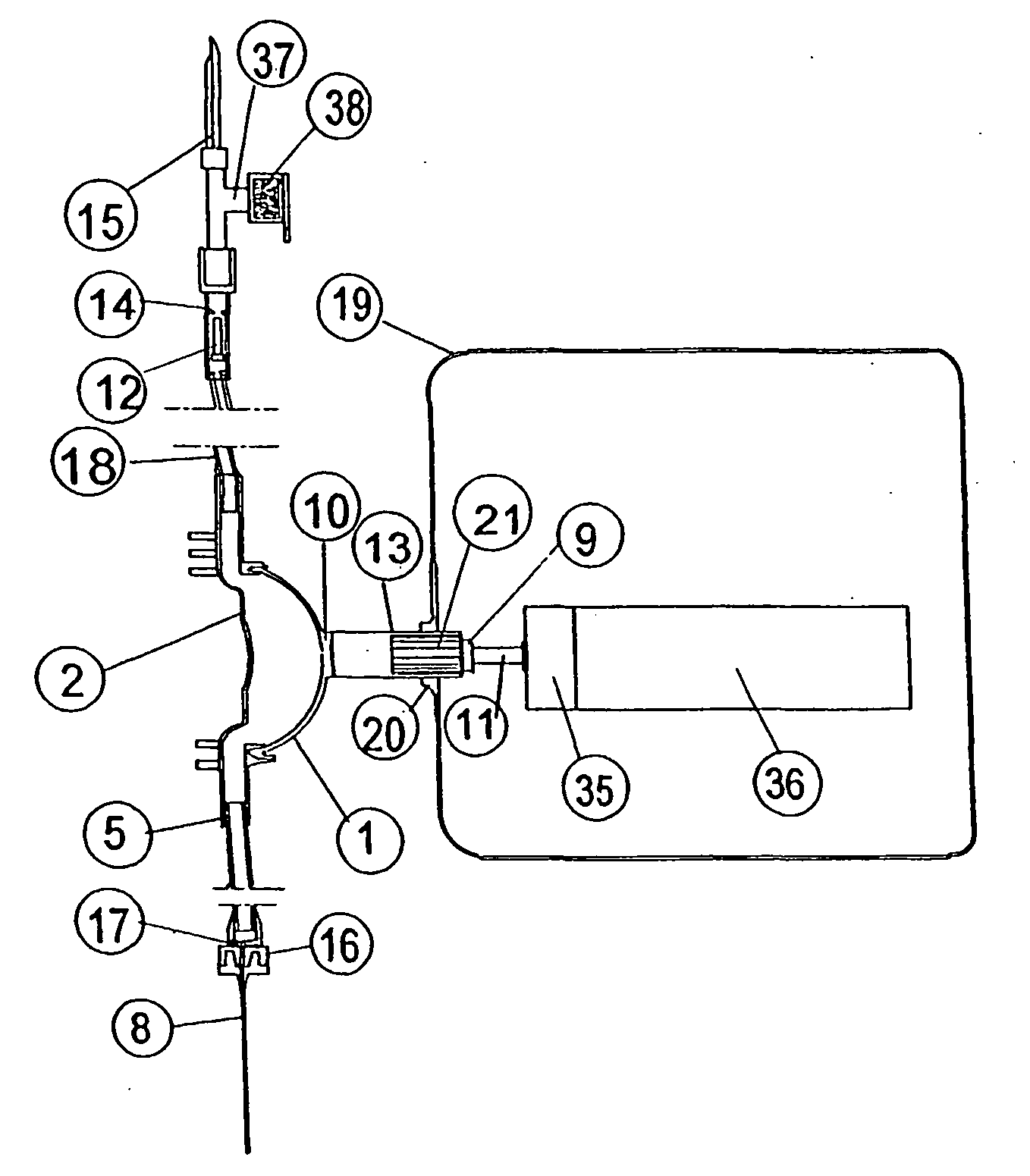

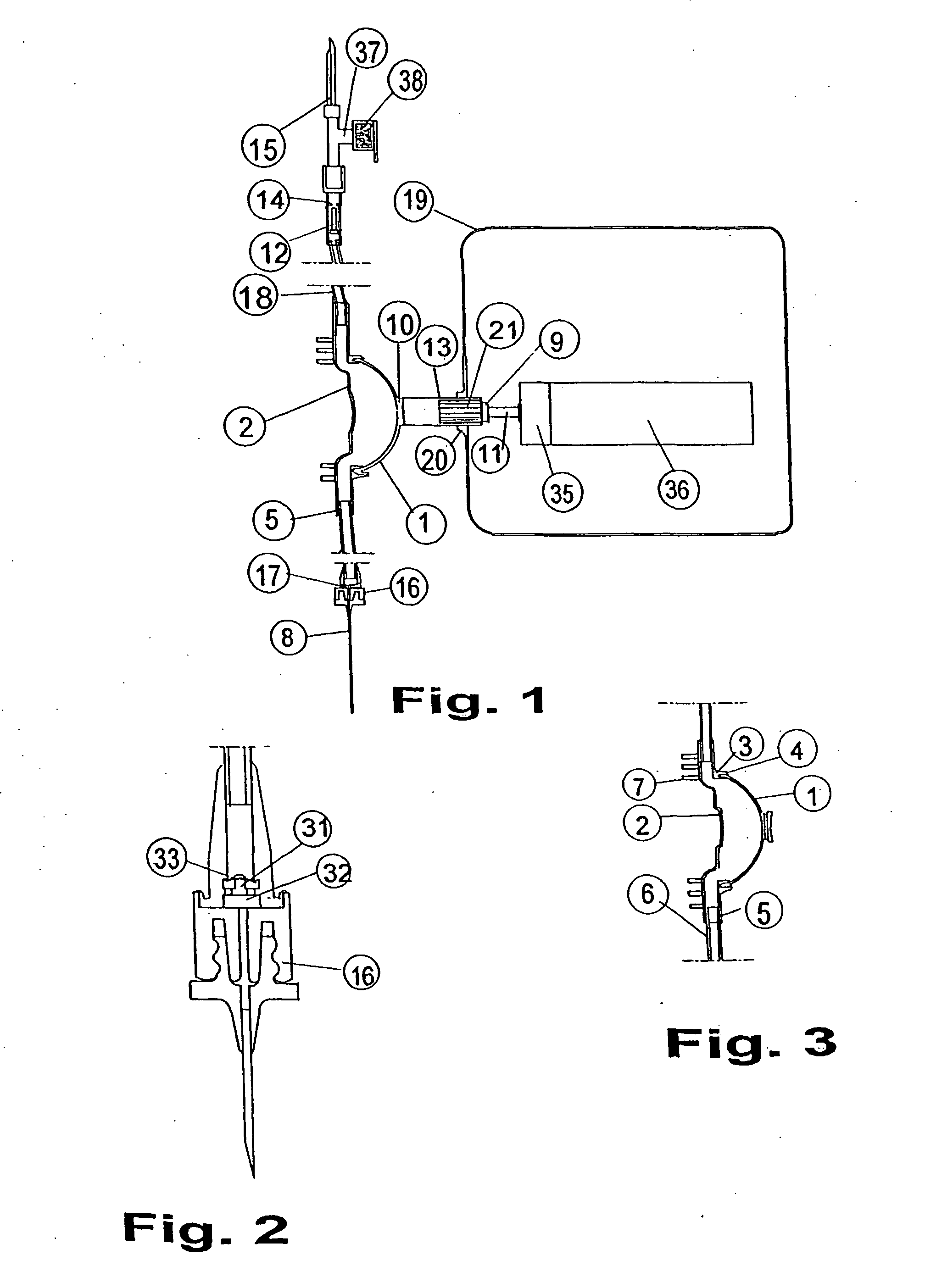

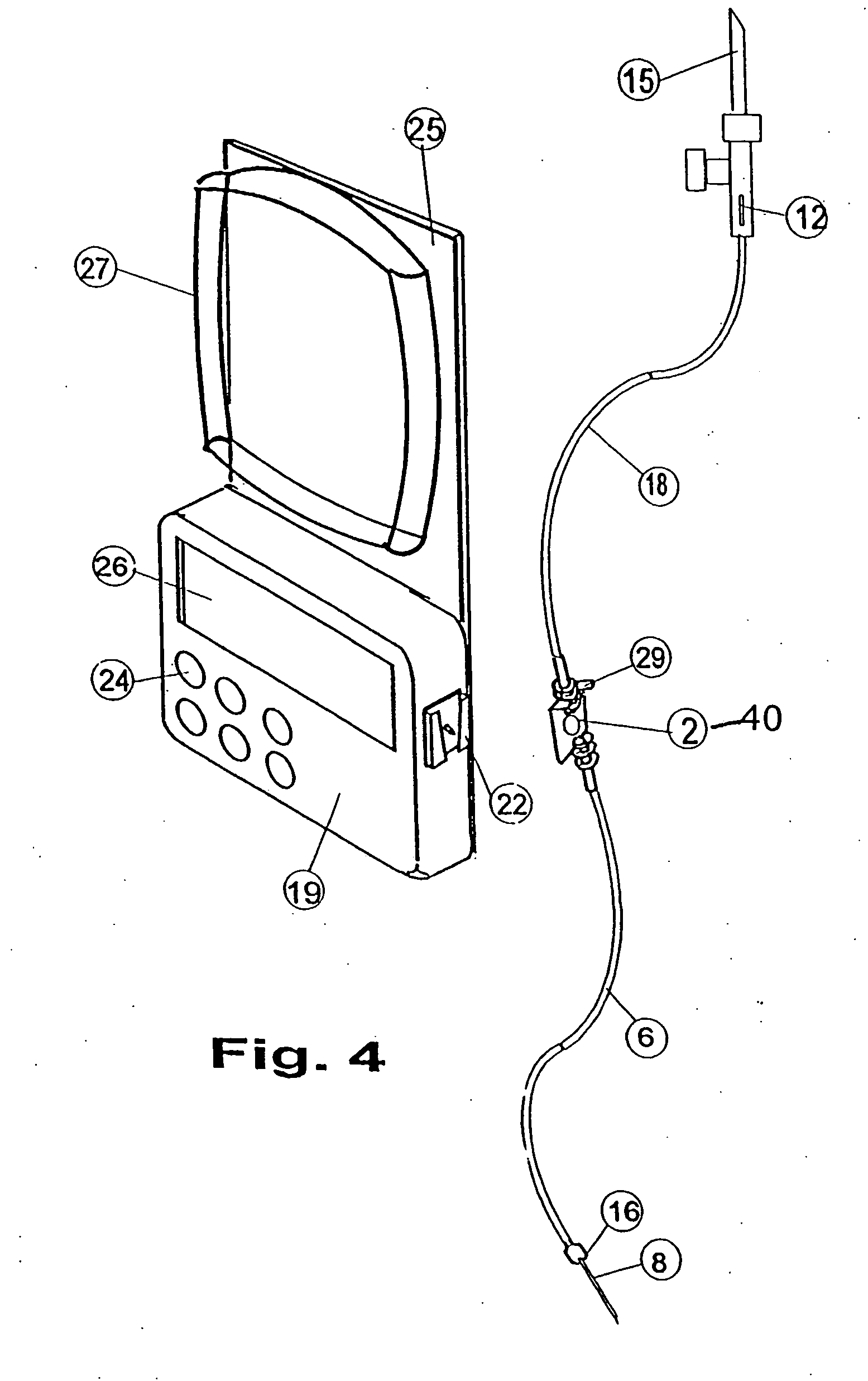

[0030] The exemplary embodiment of the membrane pump of the present invention, indicated generally as the pump house 2 in FIG. 1 with the membrane 1 and connected to an inlet tube 18 and outlet tube 5, with inlet check valve 14 and outlet check valve 16, and an attachment to the injection needle 8. The liquid container is penetrated by the insert mouthpiece 15 which is connected to the inlet check valve house 14 and with a cone 12, which floats, movable longitudinally in the house 14. The air filter 38 is connected to the inlet tube 15. The device box 19 is schematic drawn and contains an electric motor 36 with gear box 35 and a screw 11 which when rotated moves the threaded piston 9 longitudinally and the elongation of the piston 13 which presses the membrane inwards and lets the membrane 1 free for recoiling, whereas the membrane pump is filled with liquid. The elongation 13 of the piston 9 has splines 21 which fit in corresponding tapping in the gablesocket 20 in the device box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com