Semiconductor device and memory card using the same

a technology of semiconductor elements and memory cards, applied in the direction of semiconductor/solid-state device details, electrical apparatus construction details, printed circuit non-printed electric components association, etc., can solve the problems of easy-to-cause characteristic degradation of semiconductor elements, low cutting speed, and inability to machining efficiency down in the cutting step of the circuit board fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

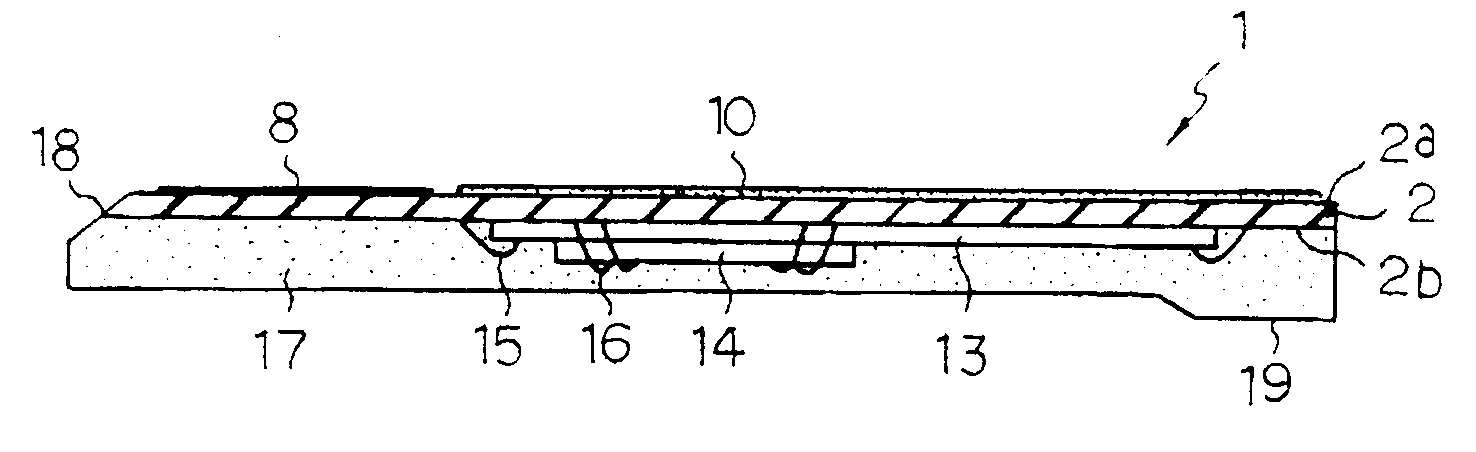

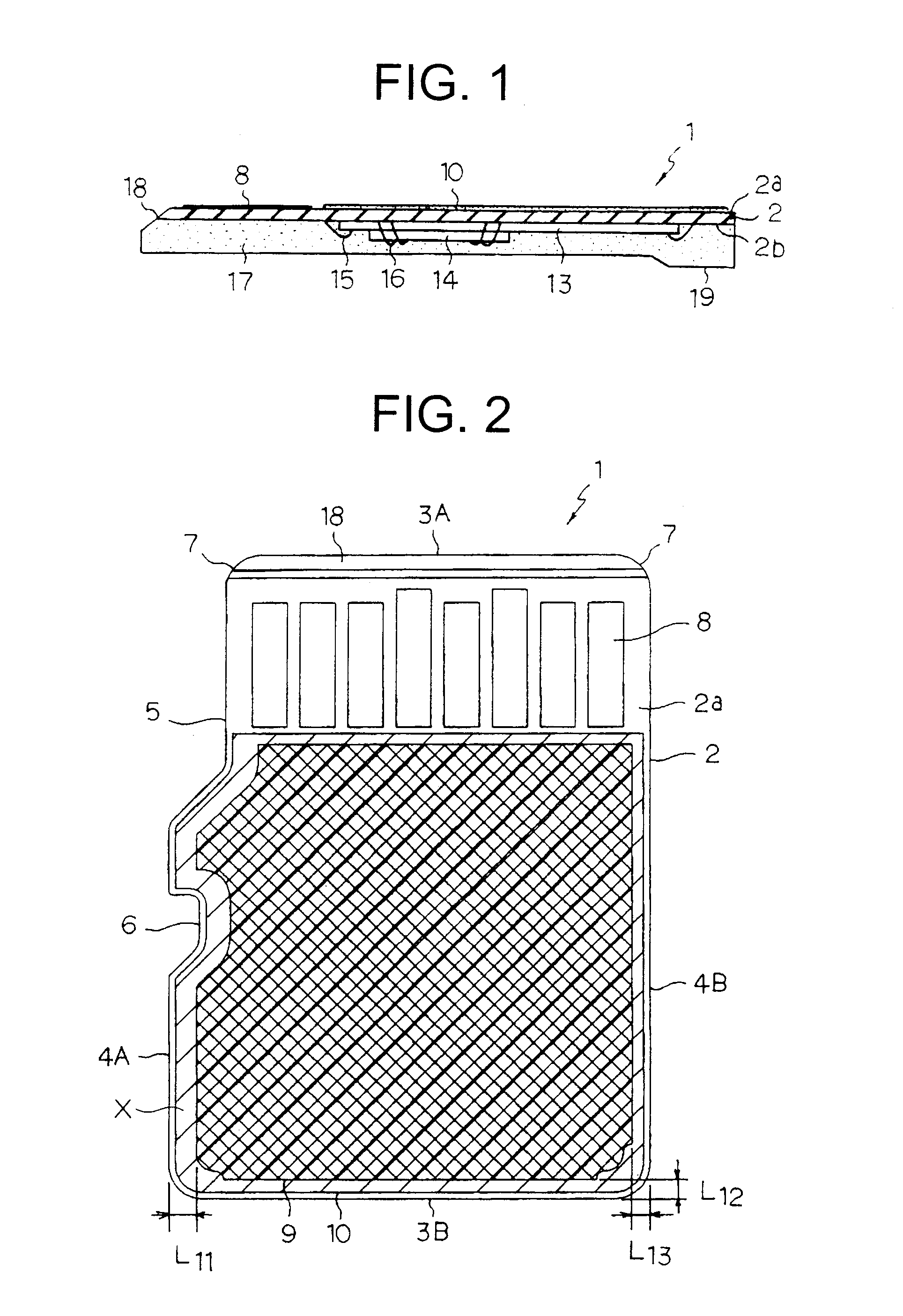

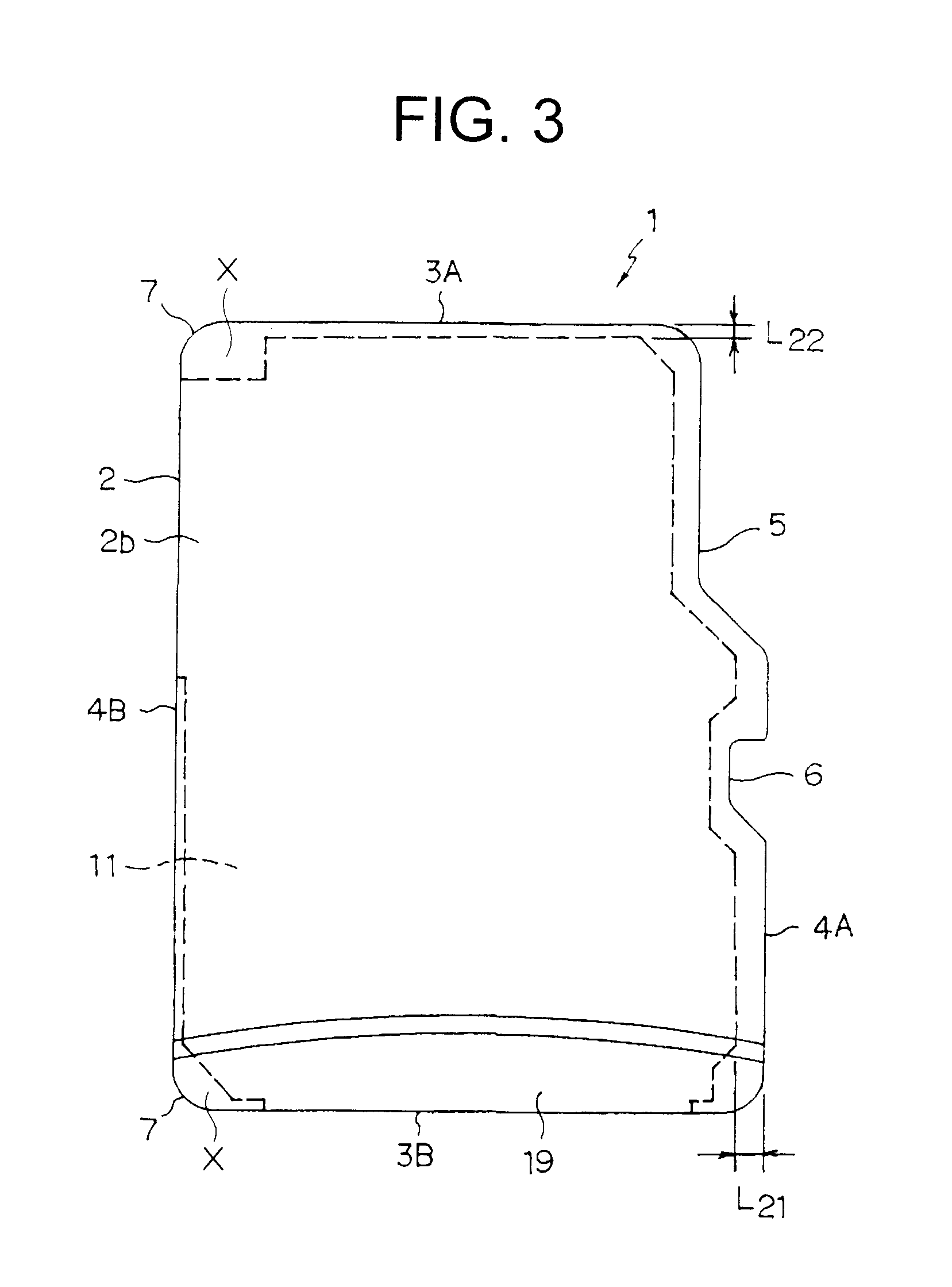

[0022]Hereinafter, a mode to embody the present invention will be described with reference to the drawings. FIG. 1, FIG. 2 and FIG. 3 are views showing a structure of a semiconductor device according to an embodiment of the present invention, in which FIG. 1 is a sectional view of the semiconductor device, FIG. 2 is a plan view (upper view) thereof and FIG. 3 is a rear view thereof. A semiconductor device 1 shown in these view is composed of a memory card, and the semiconductor device 1 is used by itself as, for example, a micro SD™ standard memory card (microSD™ card). The semiconductor device 1 includes a circuit board 2 serving as a terminal forming substrate and an element mounting substrate.

[0023]The circuit board 2 is formed, for example, by providing a wiring network inside or on a surface of an insulating resin substrate, and specifically, a print circuit board using glass epoxy resin, BT resin (Bsmaleimide-Triazine resin) or the like is applicable. The circuit board 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com