Treatment of Pulp Stocks Using Oxidative Enzymes to Reduce Pitch Deposition

a technology of oxidative enzymes and pulp stocks, which is applied in the direction of pulp liquor regeneration, cellulose treatment using microorganisms/enzymes, microorganism/enzyme addition, etc., can solve the problems of reducing paper quality, negative affecting the physical properties of pulp, and increasing manufacturing costs, so as to reduce energy requirements, improve paper strength, and reduce apparent pitch content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

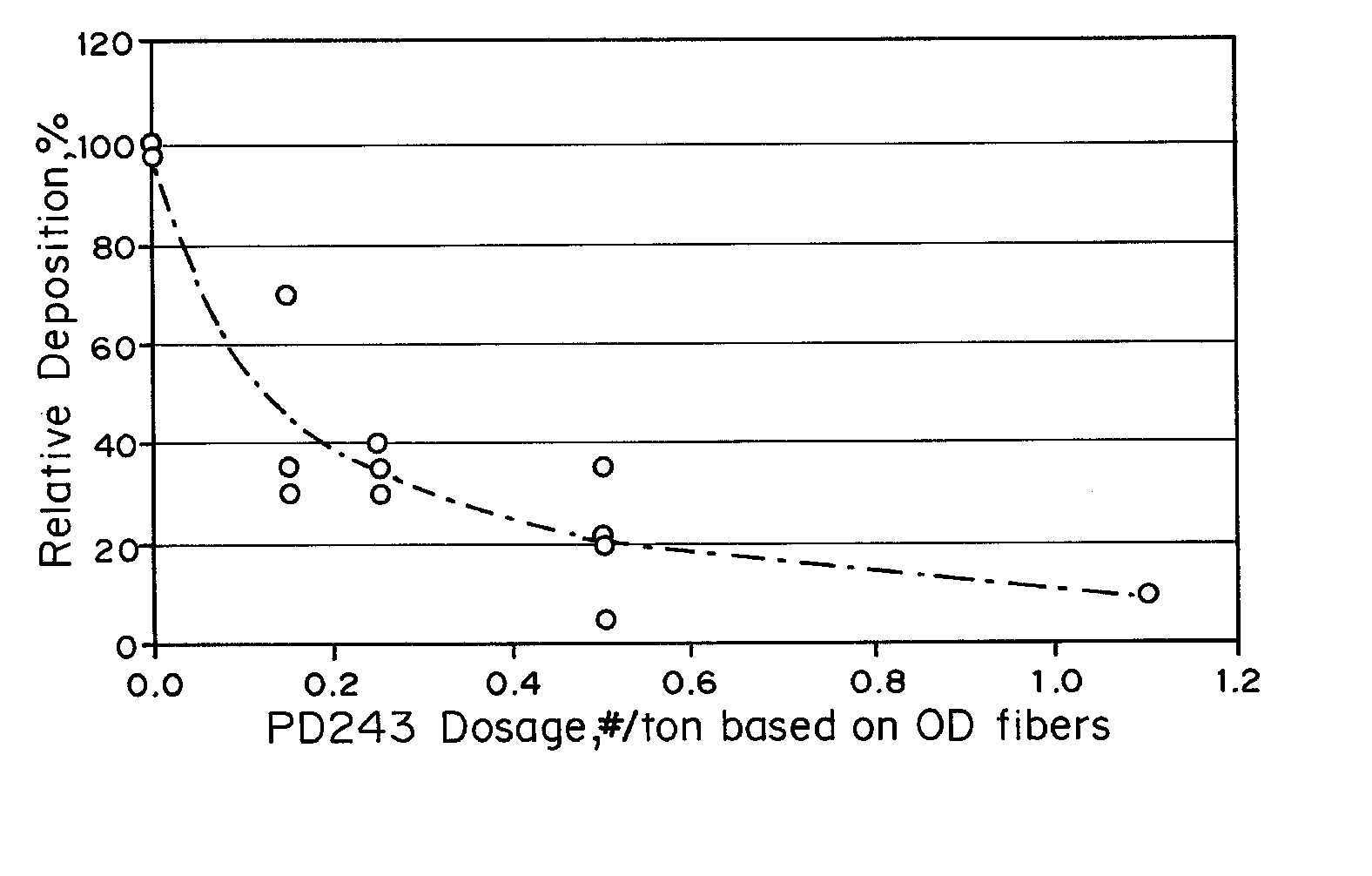

The Effect of PD243 Treatment on Pitch Deposition of Newsprint Mill A Thermomechanical Pulp Stock

[0053] The experiment was conducted following the procedure described above. The Decker accept stock from Newsprint Mill A was treated initially with EnzOx® PCX at a concentration of 0.1% based on the oven dried weight of the fibers and then with different amounts of the PD243 formulation. The results are shown in FIG. 1. FIG. 1 shows that the relative pitch deposition decreases as the dosage per ton of the enzyme formulation increases compared to the control which was not treated with the enzyme formulation.

example 2

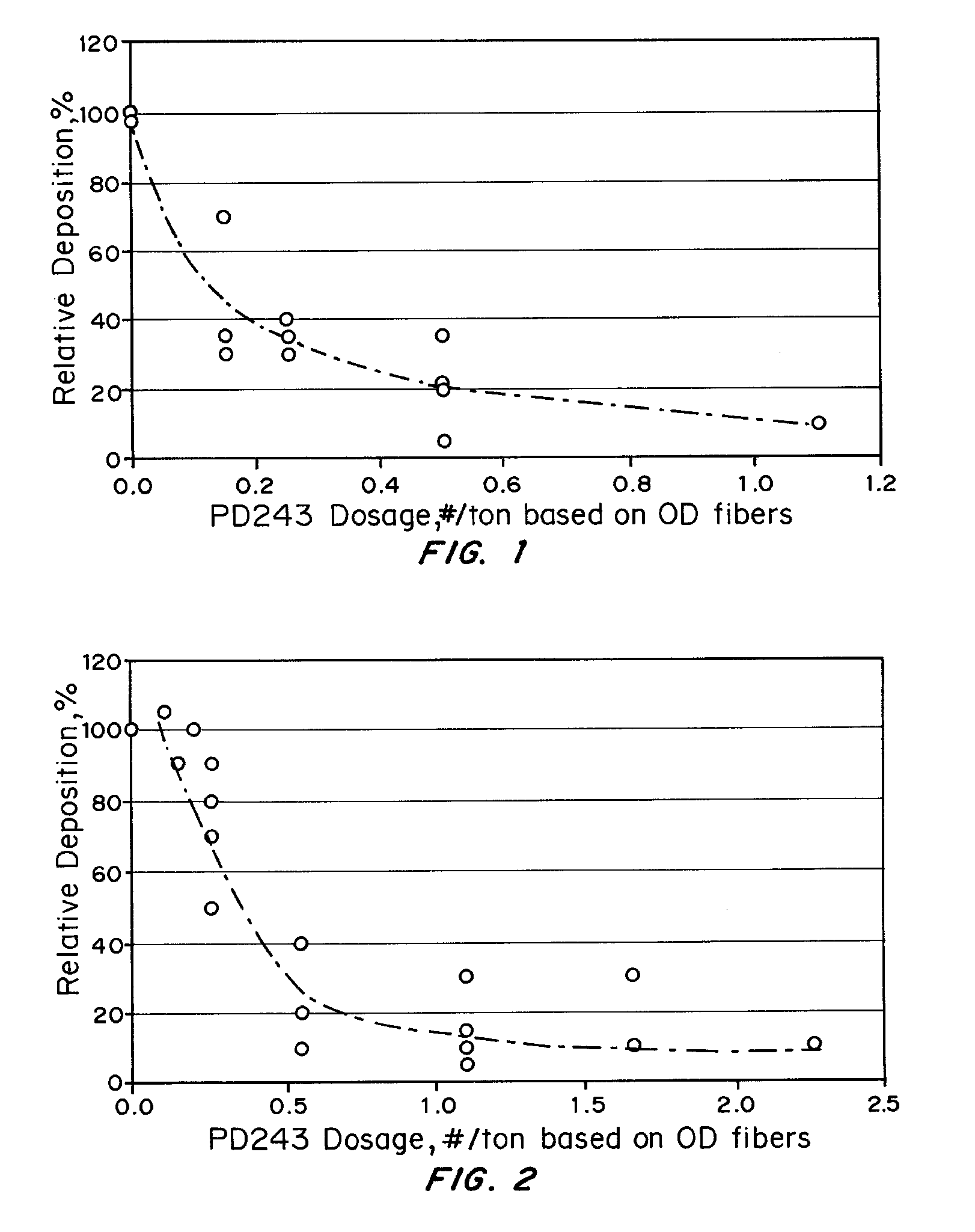

The Effect of PD243 Treatment on Pitch Deposition of Newsprint Mill B Thermomechanical Pulp Stock

[0054] The experiment was conducted following the procedure described above. The blowline stock from Newsprint Mill B was initially treated with EnzOx® PCX at a concentration of 0.1% based on the oven dried weight of the fibers and then with different amounts of the PD243 formulation. The results are shown in FIG. 2. FIG. 2 shows that the relative pitch deposition decreases as the dosage per ton of the enzyme increases compared to the control which was not treated with the enzyme formulation.

example 3

The Effect of PD247 Treatment on Pitch Deposition of Newsprint Mill A Thermomechanical Pulp Stock

[0055] The experiment was conducted following the procedure described above. The blowline stock from Newsprint Mill A was initially treated with EnzOx® PCX at a concentration of 0.1% based on the oven dried weight of the fibers and then with different amounts of the PD247 formulation. The results are shown in FIG. 3. FIG. 3 shows that the relative pitch deposition decreases as the dosage per ton of the enzyme formulation increases compared to the control which was not treated with the enzyme formulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com