Golf head and welding method thereof

a golf head and welding method technology, applied in the field of golf head and welding method thereof, can solve the problems of poor welding quality, relatively large gaps, and low production efficiency of the conventional method of welding the golf head, and achieve the effects of improving welding speed, improving welding quality, and improving welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

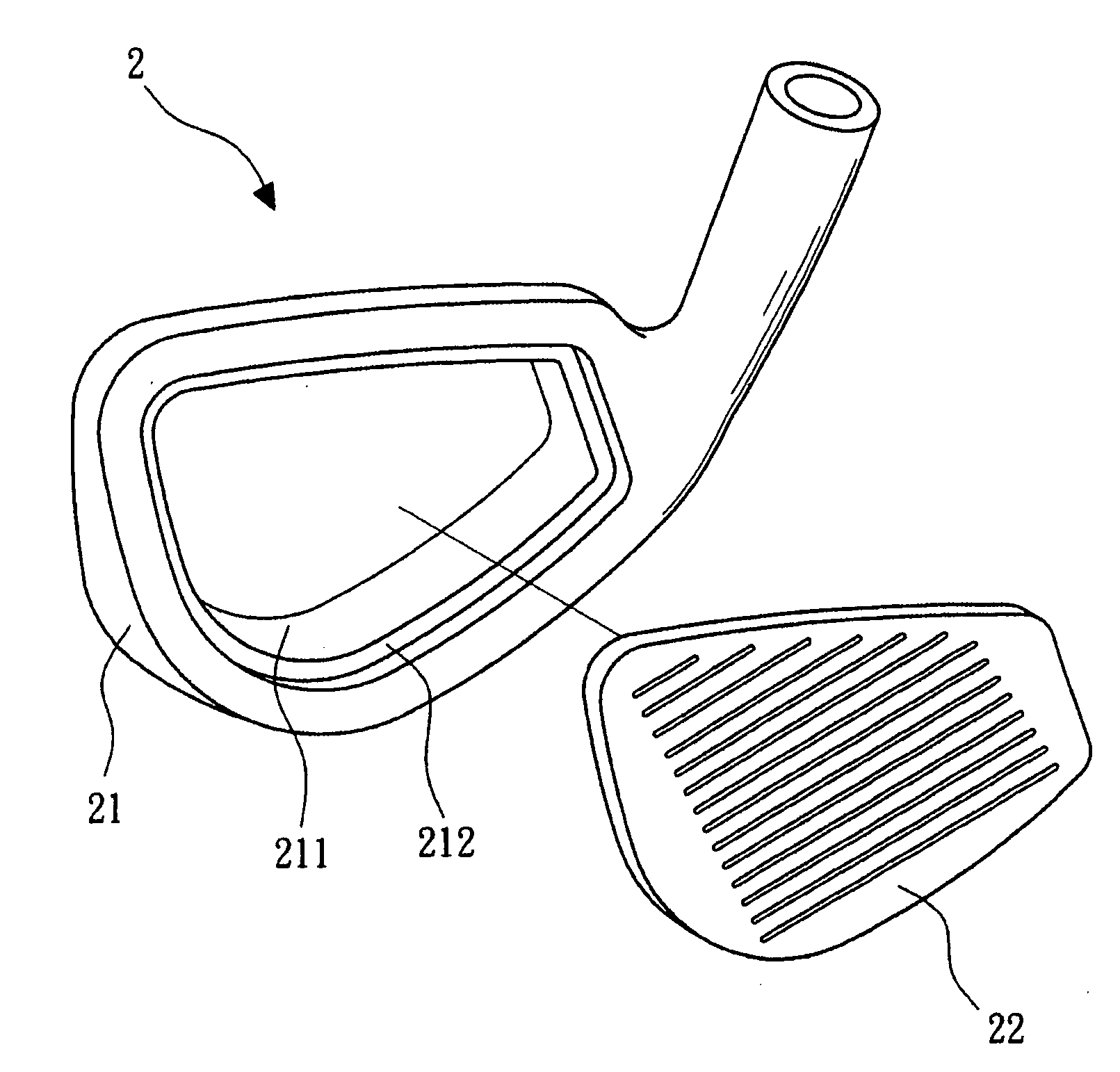

[0034]Referring to FIGS. 2A and 2B, they are schematic views of a golf head according to a first embodiment of the present invention. The golf head 2 comprises a metal body 21 and a metal plate 22. The metal body 21 has an opening 211 with a first welding surface 212. In the embodiment, the first welding surface 212 is configured to have a right angle. The shape of the metal plate 22 matches that of the opening 211. The metal plate 22 is a striking surface, and has a second welding surface 221 opposite to the first welding surface 212. The second welding surface 221 has at least one second bump 222. In the embodiment, the second bump 222 is an annular flange, as shown in FIG. 2C. In other applications, the second bump222 can also be a round protrusion, as shown in FIG. 2D, or an elongated bump, as shown in FIG. 2E.

[0035]It should be noted that, the first welding surface 212 can also have at least one first bump 213, as shown in FIG. 2F. Alternatively, the first bump 213 and the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| shapes | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com