Air-conditioning unit and air-conditioning apparatus

a technology of air conditioning unit and air conditioner, which is applied in the direction of domestic cooling apparatus, vehicle heating/cooling device, vehicle components, etc., can solve the problems of difficult to satisfy the condition tdef>tfoot, the windshield cannot be heated to a sufficient temperature, etc., and achieves the effect of reducing mixing distance, easy flow, and increasing the temperature difference between the conditioned air in the high-temperature air channel and the low-temperature air channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

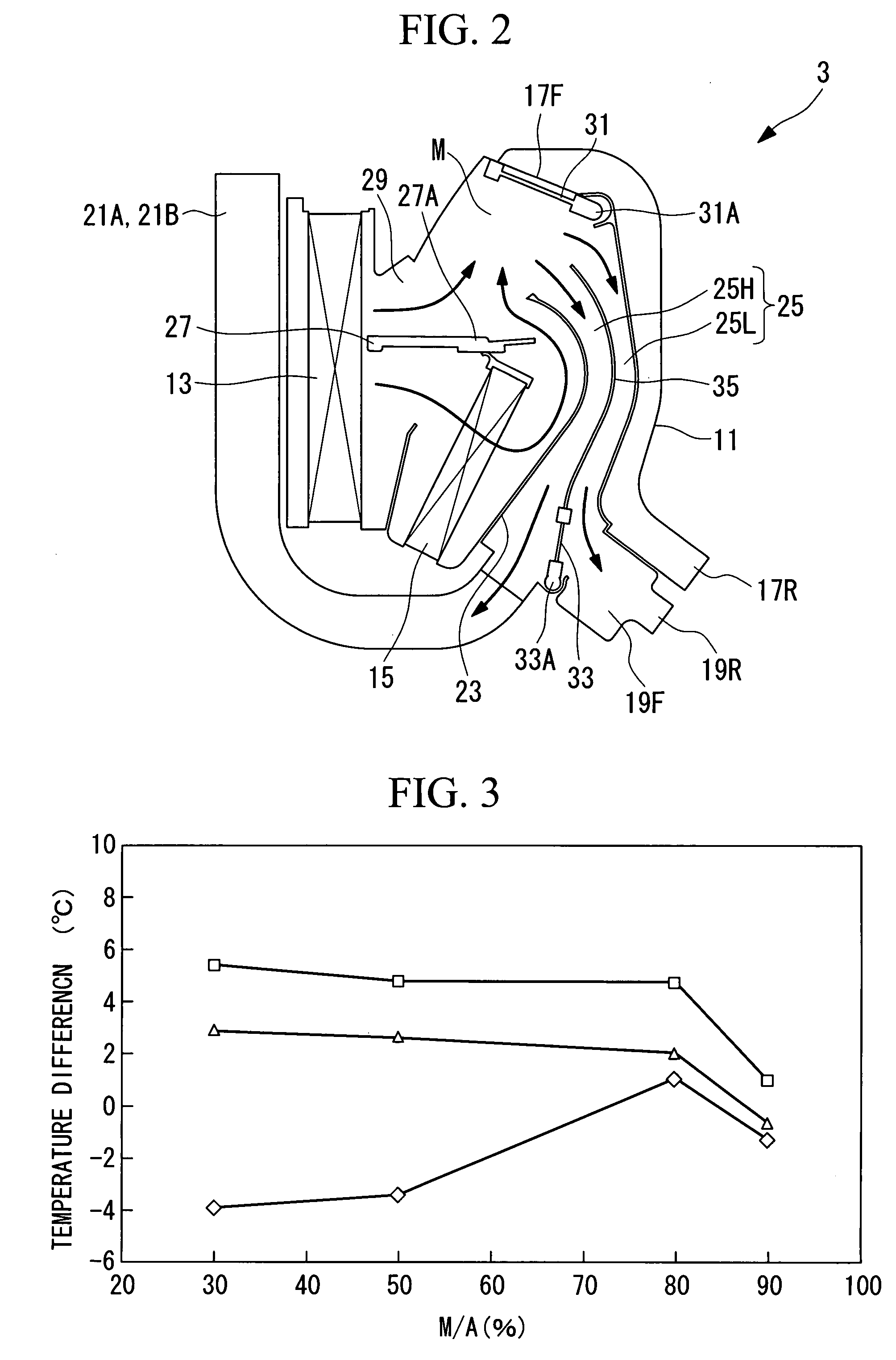

[0057]A vehicle air-conditioning apparatus according to a first embodiment of the present invention will be described below with reference to FIGS. 1 to 6.

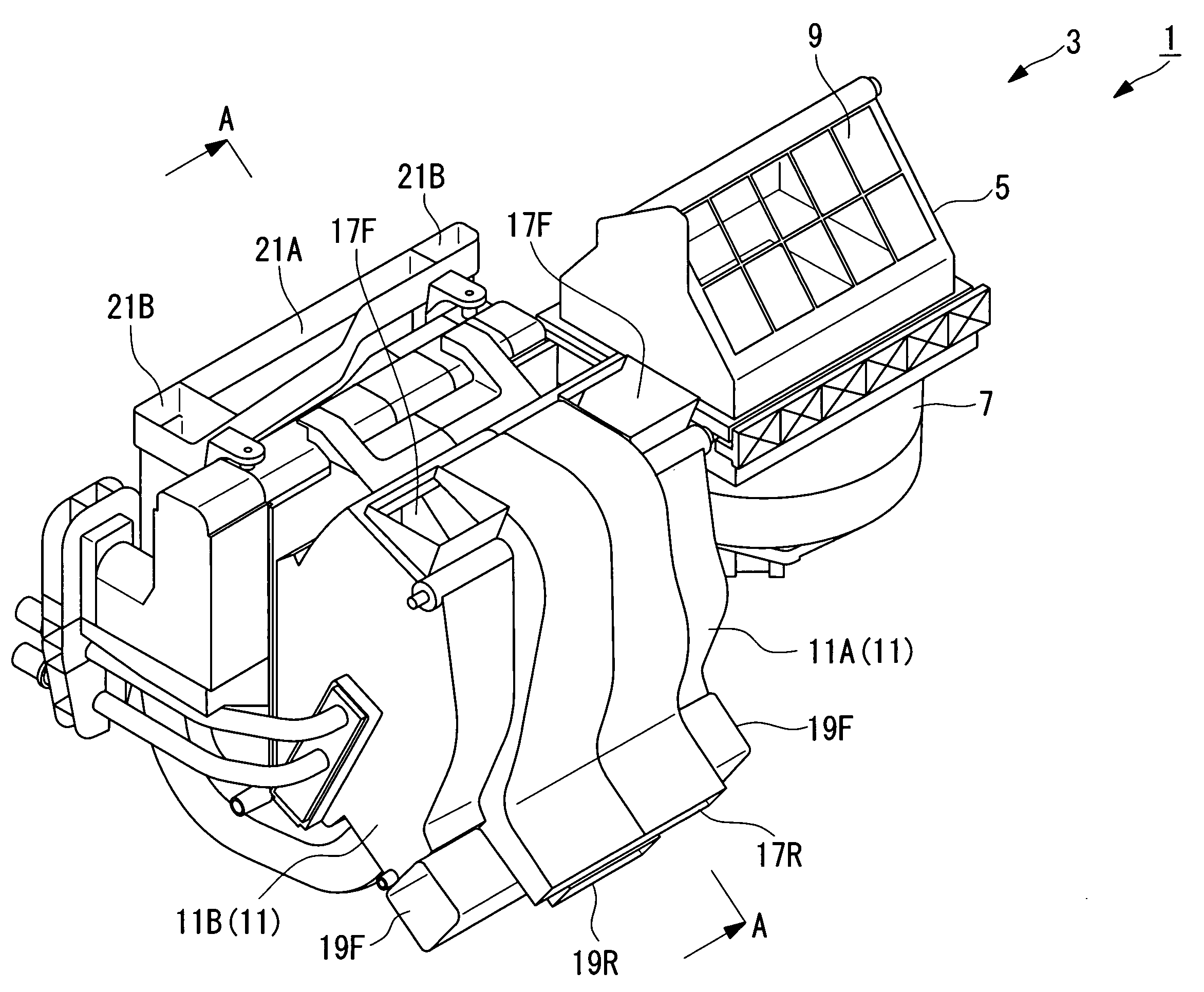

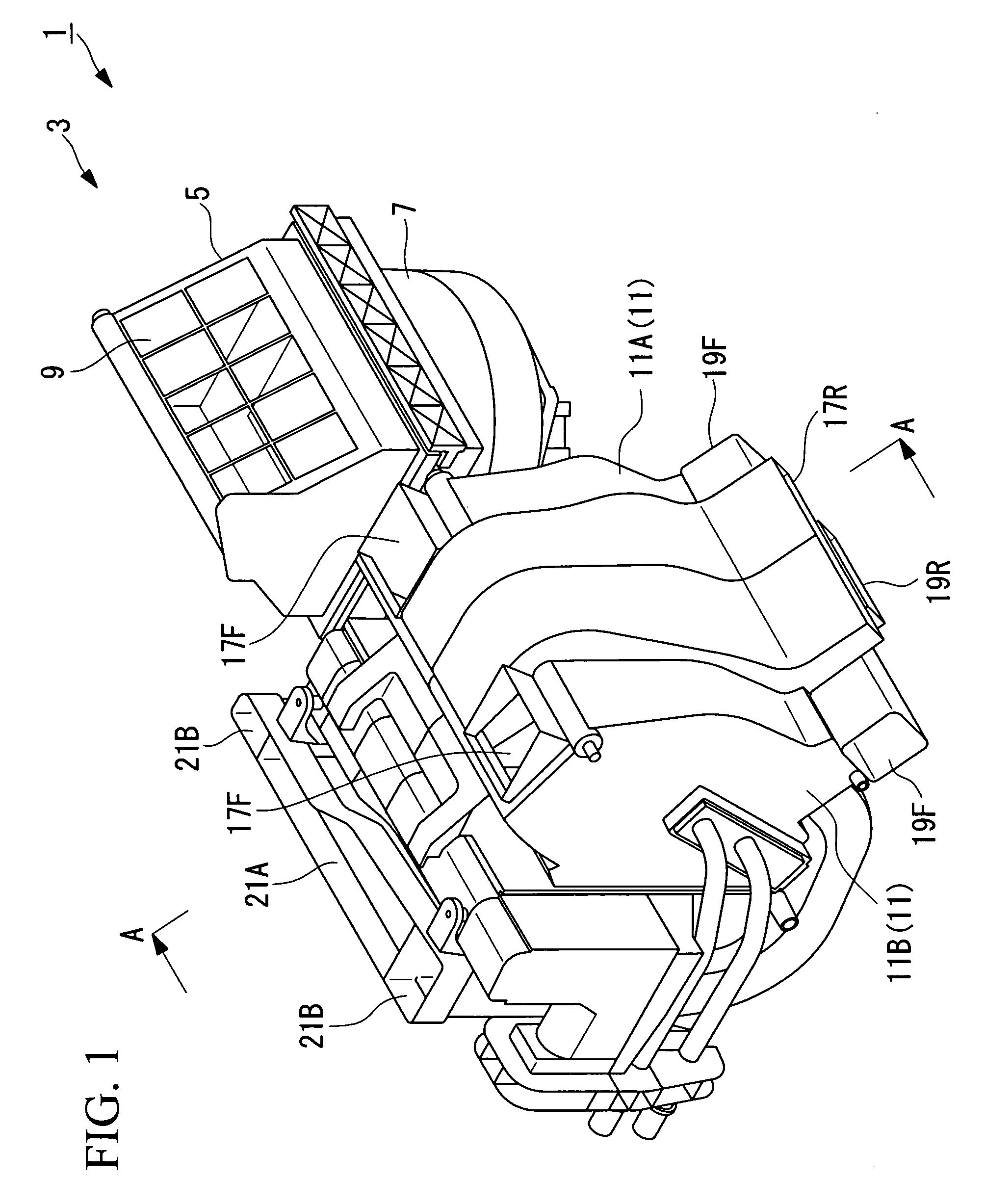

[0058]FIG. 1 is a perspective view illustrating the overall structure of an HVAC unit of the vehicle air-conditioning apparatus according to this embodiment.

[0059]As shown in FIG. 1, an interior / exterior-air switching box 5 and a blower fan 7 are attached to an HVAC unit (air-conditioning unit) 3 of a vehicle air-conditioning apparatus (air-conditioning apparatus) 1. An interior / exterior-air switching damper 9 is attached on the interior / exterior-air switching box 5. By operating the interior / exterior-air switching damper 9, the interior / exterior-air switching box 5 selectively takes in vehicle interior air (interior air) or vehicle exterior air (exterior air).

[0060]In the description below, unconditioned interior or exterior air taken in from the interior / exterior-air switching box 5 is collectively referred to as “intake air”, a...

first modification

of First Embodiment

[0114]Next, a first modification of the first embodiment will be described with reference to FIGS. 7 to 11.

[0115]The basic structure of the vehicle air-conditioning apparatus according to this modification is the same as that according to the first embodiment, except that the shape of the guide vane differs. Therefore, in this modification, only the shape of the guide vane and its vicinity will be described with reference to FIGS. 7 to 11, and descriptions of other components will be omitted.

[0116]FIG. 7 is a schematic view illustrating the positional relationship of a guide vane and a switching damper in an HVAC unit in a vehicle air-conditioning apparatus according to this modification.

[0117]Components according to this modification that are the same as those in the first embodiment will be represented with the same reference numerals.

[0118]As shown in FIG. 7, an HVAC unit (air-conditioning unit) 103 of a vehicle air-conditioning apparatus (air-conditioning appa...

second modification

of First Embodiment

[0156]Next, a second modification of the first embodiment of the present invention will be described with reference to FIG. 12.

[0157]The basic structure of a vehicle air-conditioning apparatus according to this modification is the same as that according to the first embodiment, except that the shape of the guide vane differs. Therefore, in this modification, only the shape of the guide vane and its vicinity will be described with reference to FIG. 12, and descriptions of other components will be omitted.

[0158]FIG. 12 is a schematic view illustrating the positional relationship of a guide vane and a switching damper in an HVAC unit in a vehicle air-conditioning apparatus according to this modification.

[0159]Components according to this modification that are the same as those in the first embodiment will be represented with the same reference numeral.

[0160]As shown in FIG. 12, an HVAC unit (air-conditioning unit) 203 of a vehicle air-conditioning apparatus (air-cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com