Integrated NGL recovery in the production of liquefied natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

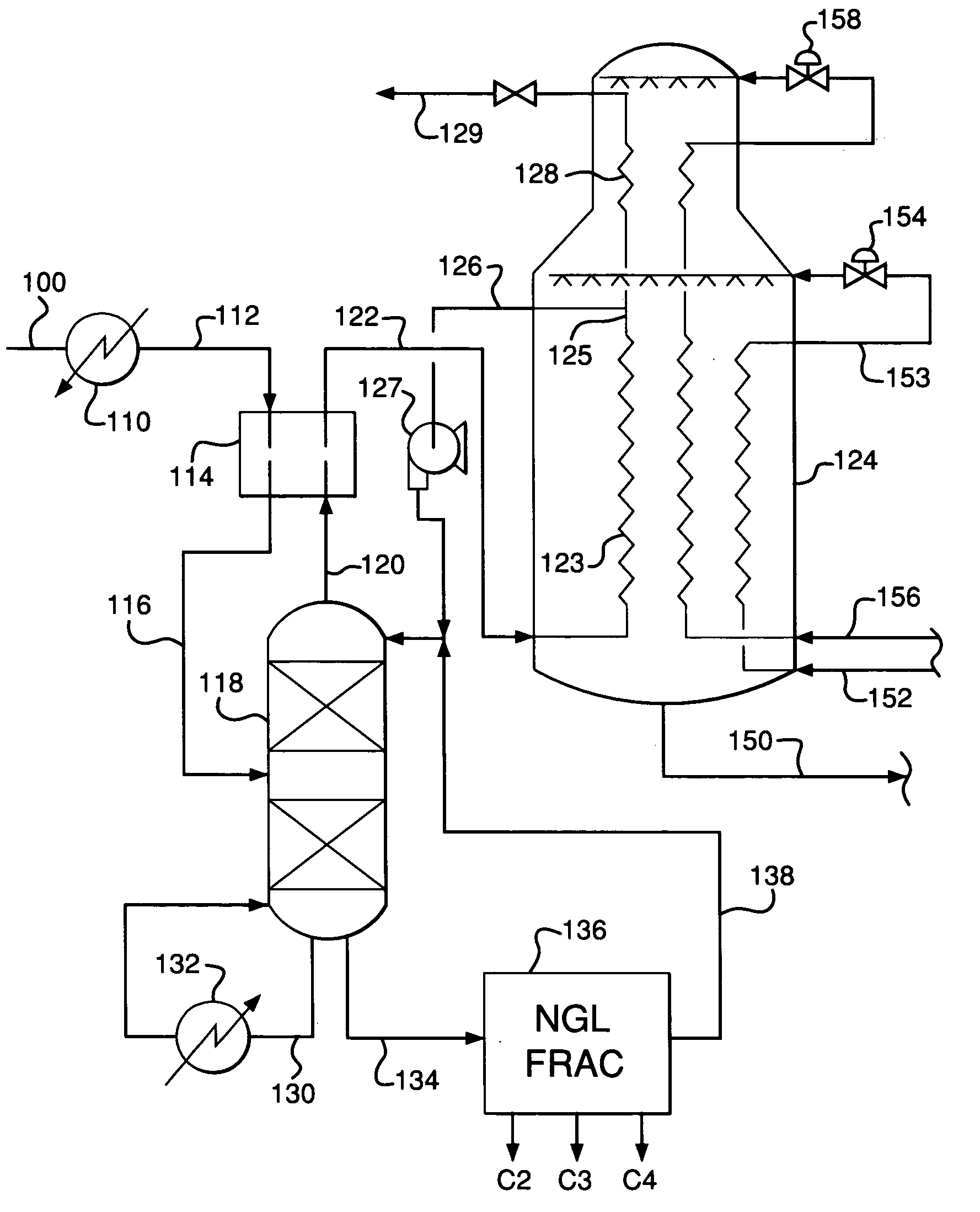

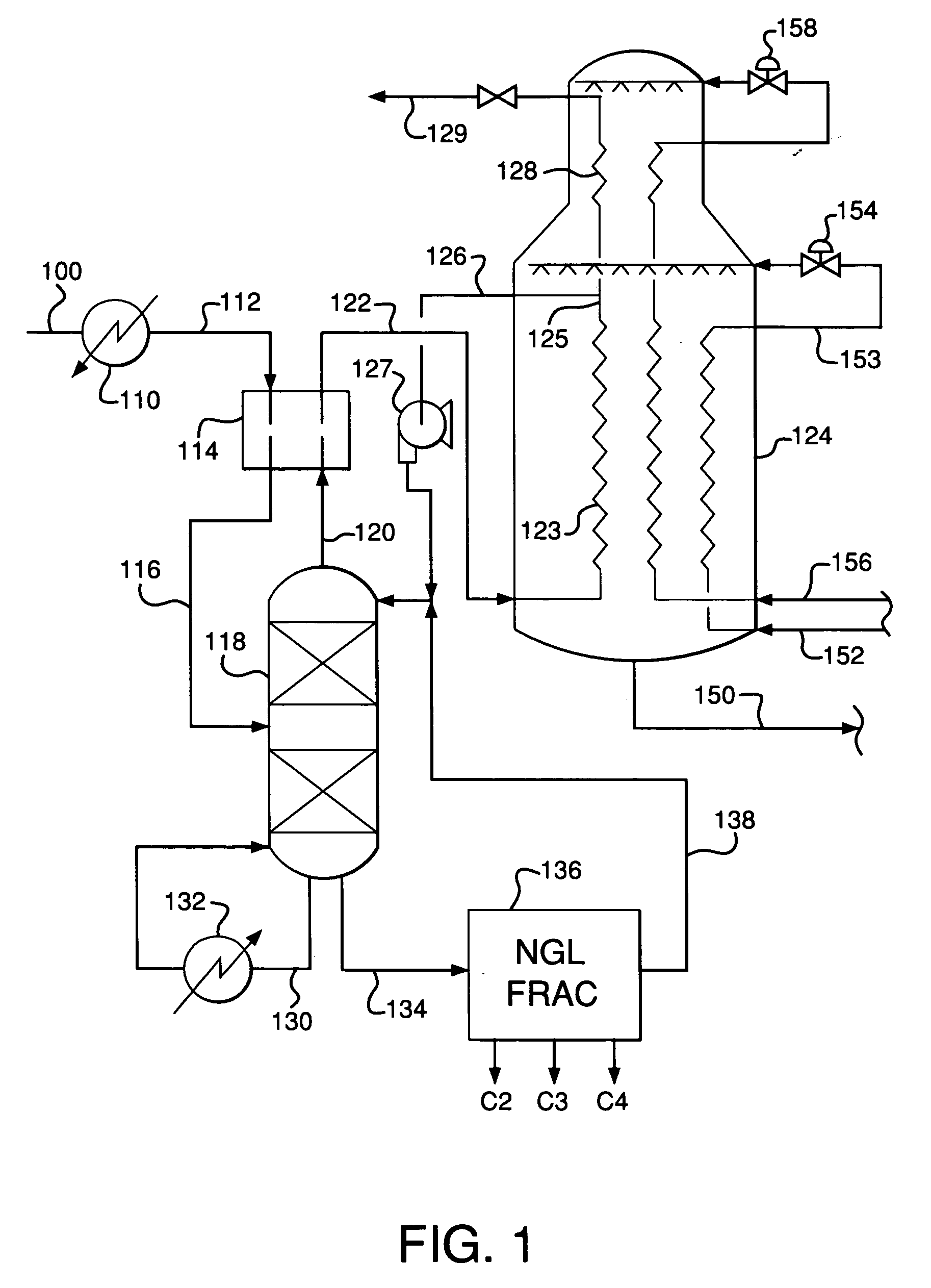

[0086]A process simulation was carried out to illustrate the embodiment of FIG. 1. A pre-purified natural gas stream in line 100 has a flow rate of 100,000 μmol / hr and pressure of 960 psia and contains (in mole %) 1.9% helium, 5.8% nitrogen, 83.2% methane, 7.1% ethane, 2.3% propane, 0.4% isobutane, 0.6% butane, 0.1% isopentane, 0.2% pentane, and 0.2% hexanes. The stream is cooled by three stages of propane cooling to −29° F., is further cooled in the economizer heat exchanger to −62.8° F., and is fed to scrub column 118. The column operates at an average pressure of 886 psia. Column overhead in line 120 at a flow rate of 104,770 lbmol / hr is warmed from −73° F. to −32° F. against the feed in heat exchanger 114. The resulting stream in line 122 is cooled and liquefied in passage 123 of the warm bundle of main heat exchanger 124 to provide a condensed methane-enriched stream in line 125. A portion of this liquid is withdrawn via line 126 at a flow rate of 10,943 lbmol / hr and temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com