Operation of a steam methane reformer by direct feeding of steam rich producer gas from steam hydro-gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

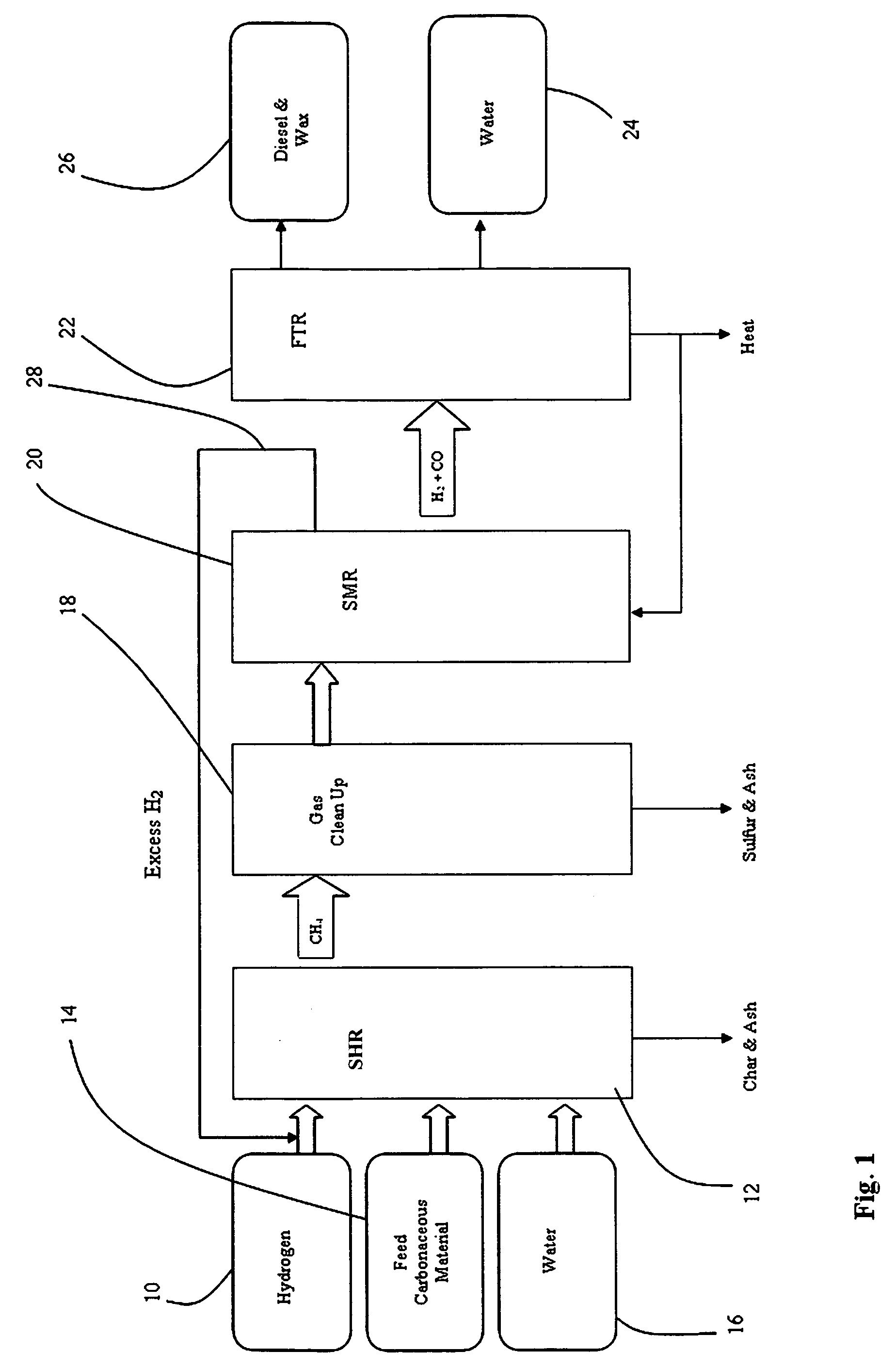

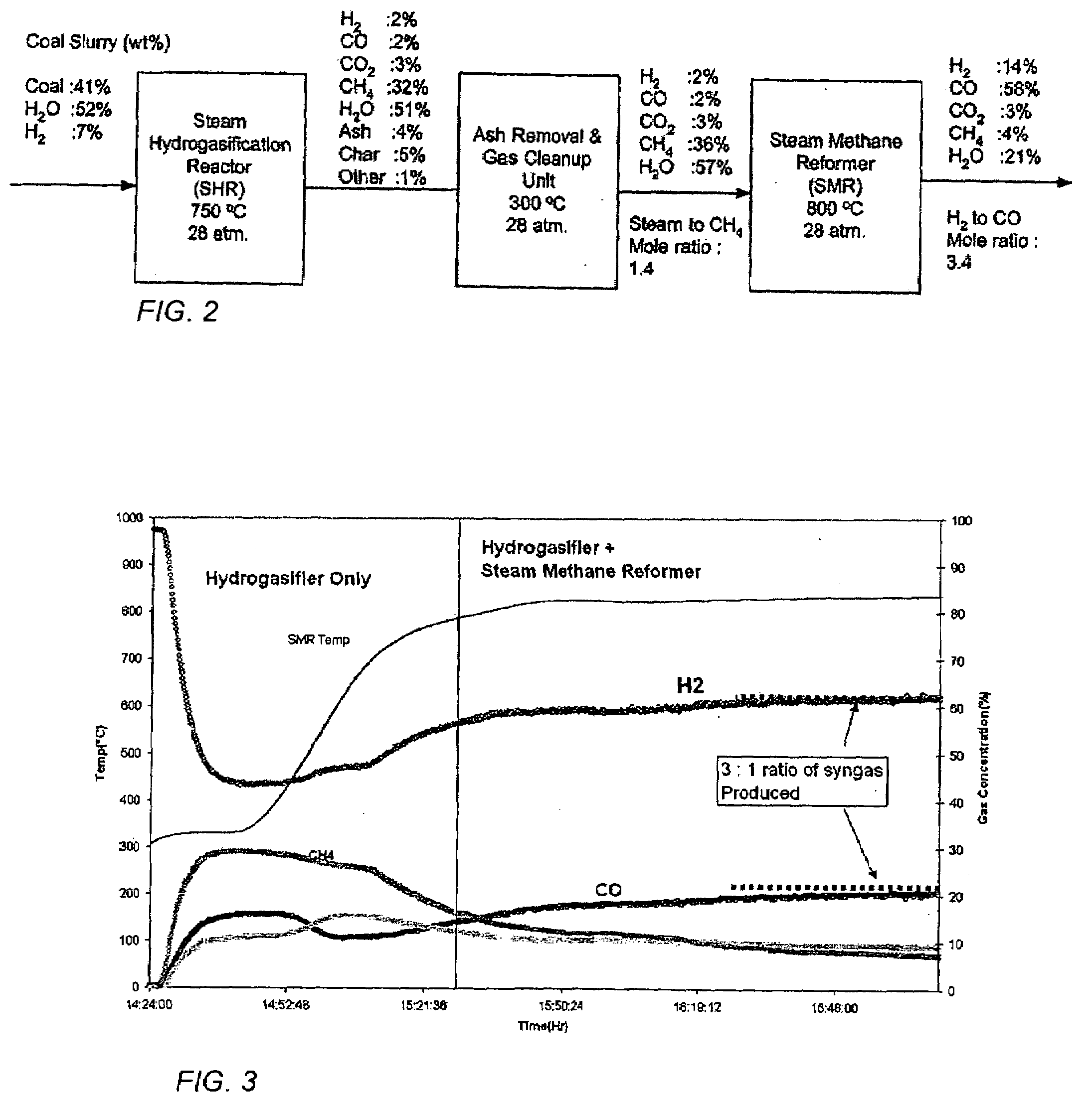

[0020]This invention provides a combination of procedures, where in one embodiment of the invention, the feedstock for an SMR is a mixture of steam and methane rich product gas generated by means of hydro-gasification of a mixture of carbonaceous material and water in an SHR. The steam is present as a result of superheating the water in the feedstock and serves as an ideal feed stream for the SMR.

[0021]The other procedure requires a method of removing impurities from the product stream from the SHR, such as fine particles of ash & char, hydrogen sulfide (H2S) and other inorganic components. These impurities must be removed in order to prevent poisoning of the catalyst used in the SMR while maintaining the SMR feed stream at its high process temperatures. Accordingly, in another embodiment of the invention, a gas cleanup unit is provided that operates at process temperatures and pressures and is located in between the SHR and SMR.

[0022]Referring to FIG. 1, a flow diagram of the proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com