System and method for dispensing an aqueous urea solution into an exhaust gas stream

a technology of aqueous urea and aqueous solution, which is applied in the direction of machines/engines, engine components, mechanical apparatus, etc., can solve the problems of current urea injection system, overheating and potential valve plugging, and other problems inherent in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

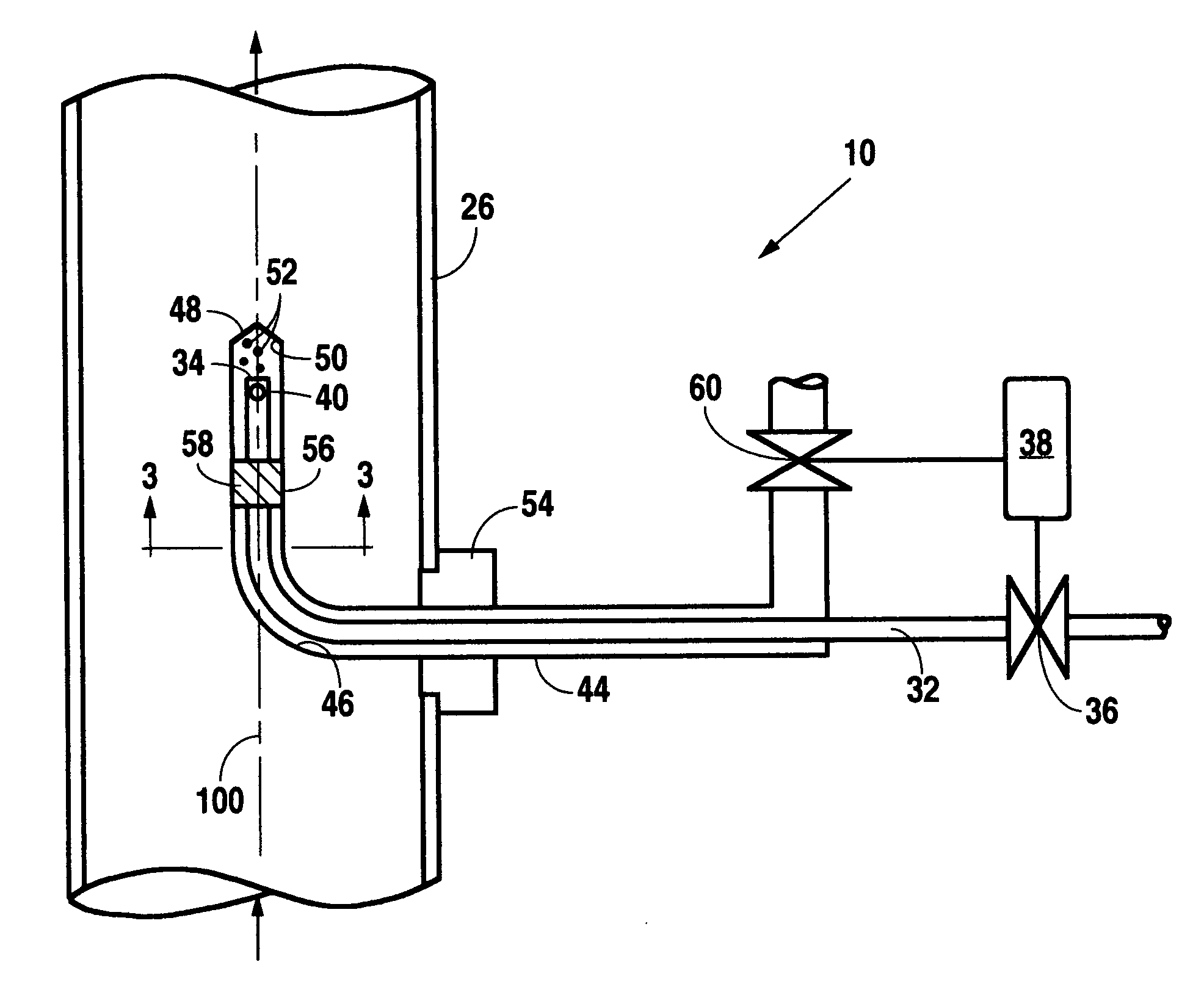

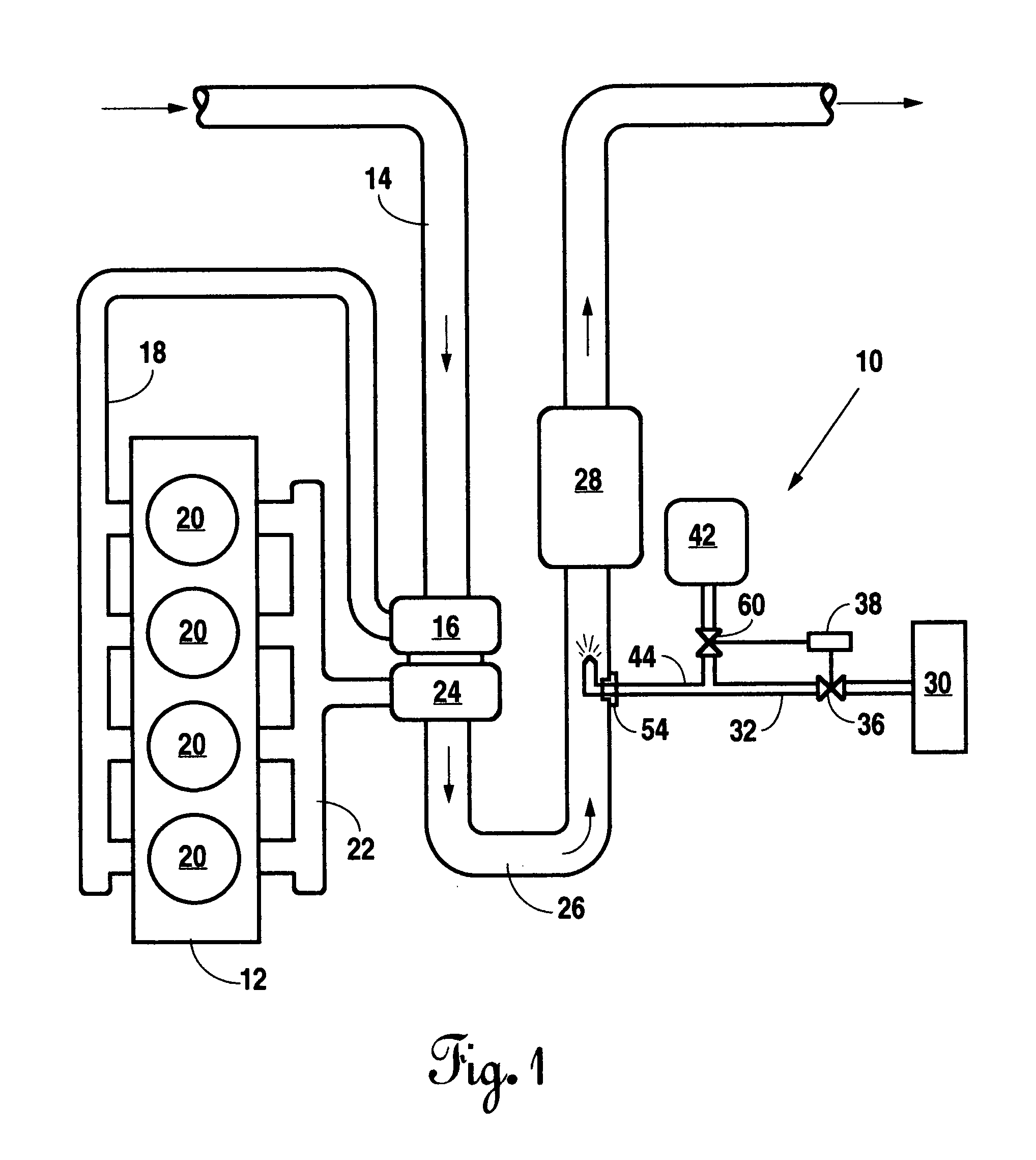

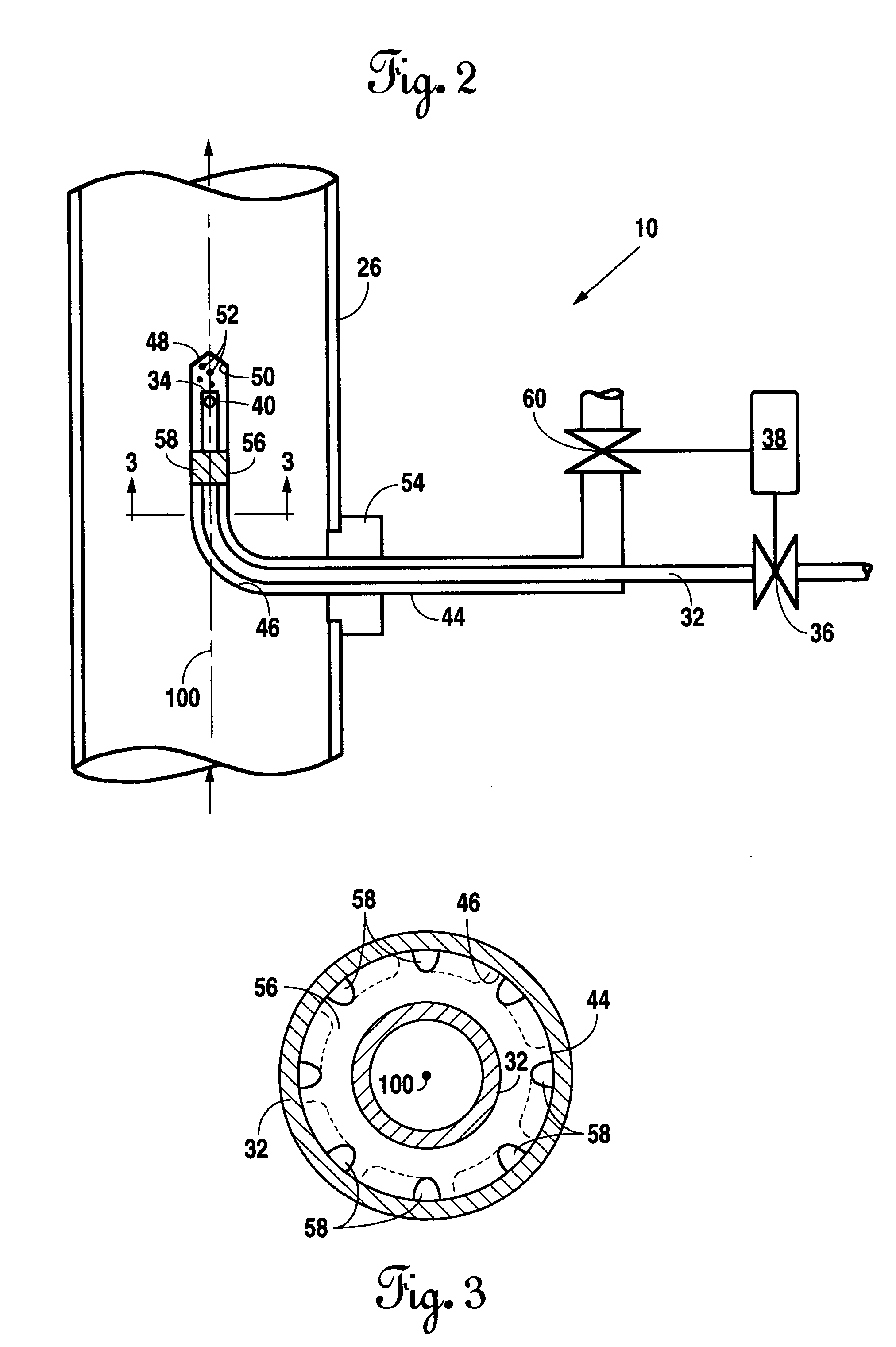

[0022]A preferred embodiment of the system for dispensing an aqueous urea solution into an exhaust gas stream is illustrated in FIGS. 1-3. In FIG. 1, an illustrative application for a system for dispensing an aqueous urea solution in an exhaust gas stream, in accordance with the present invention, is generally indicated by the reference numeral 10. In the illustrative application, the system 10 is used to dispense an aqueous urea solution into the exhaust stream of a conventional diesel engine 12. In the simplified illustrated application, the diesel engine 12 has an air intake duct 14 through which an intake air charge is inducted into a compressor stage 16 of a turbocharger and then conducted through an intake manifold 18 into a plurality of combustion chambers 20. The intake air charge is mixed with fuel in the combustion chambers 20, combusted and discharged through an exhaust manifold 22 into a turbine stage 24 of the turbocharger. After discharge from the turbocharger 24, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com