Textiles with High Water Release Rates and Methods for Making Same

a technology of high water release rate and textiles, applied in the field of textiles, can solve the problems of relatively slow drying time of garments that wick quickly, and low water release rate, and achieve the effects of improving the water release rate of fibers, yarns, fabrics,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Treated T-Shirt Liquid Contents

[0091] A 5% by weight water dispersion of PTFE was made by dilution with water from 60% solids Type 30B PTFE (Teflon®) dispersion, available from E.I. Dupont Company. Dri-release® t-shirts made from 85% Wellman Fortrel® co-polyester and 15% cotton fiber blend were then dipped either in the 5% by weight dispersion of PTFE or in water. After dipping the shirts, the shirts were manually wrung to remove as much liquid as possible. The Dri-release® t-shirt dipped in water had a 108.6% water content after hand wringing. The Dri-release® t-shirt dipped in the 5% by weight dispersion of PTFE had a 82% liquid content after hand wringing. Upon overnight drying in air, the Dri-release® t-shirt dipped in water returned to its original dry weight. The Dri-release® t-shirt dipped in the 5% by weight dispersion of PTFE dried to 104.15% of its original weight due to the additional weight of PTFE.

example 2

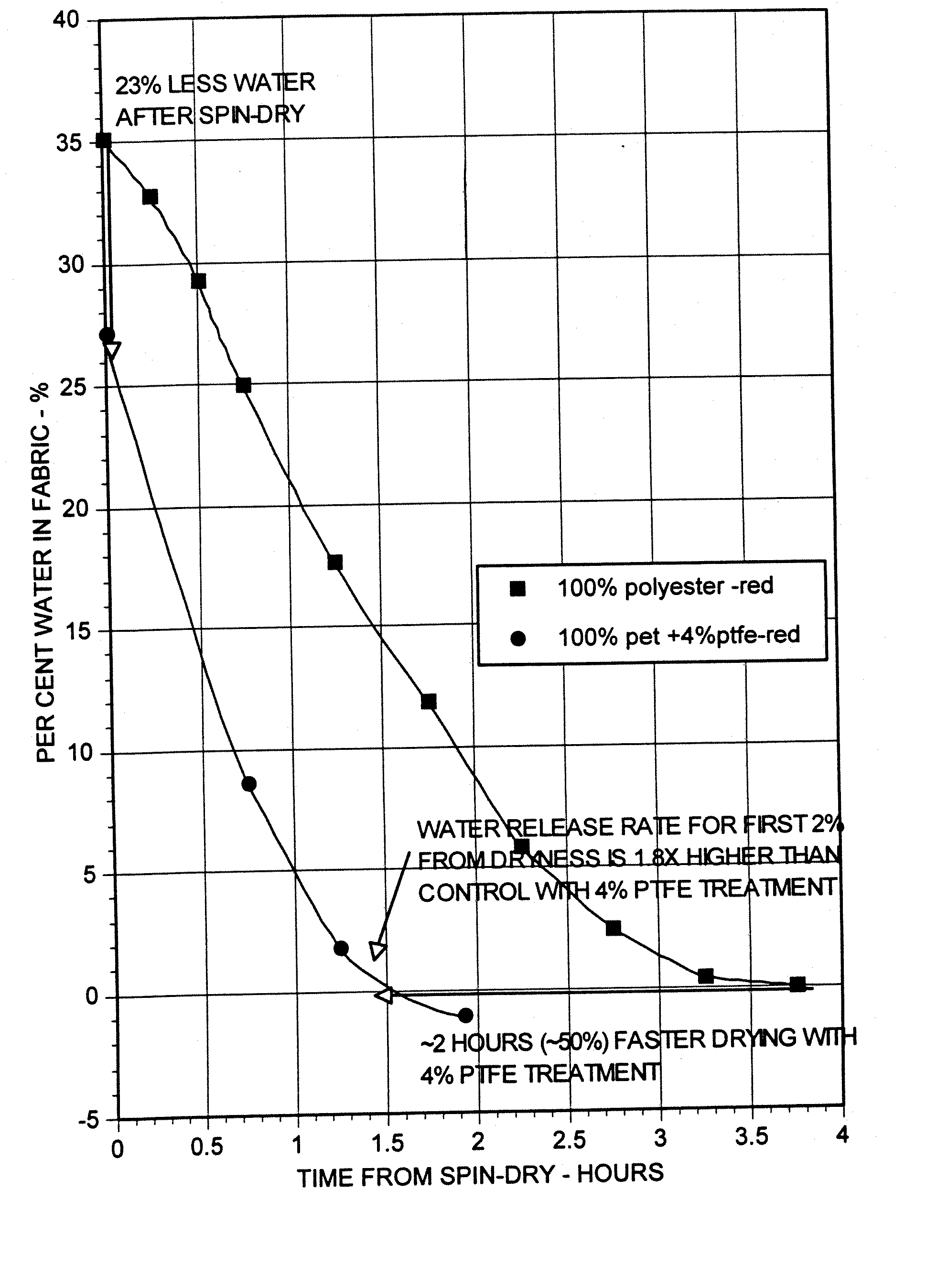

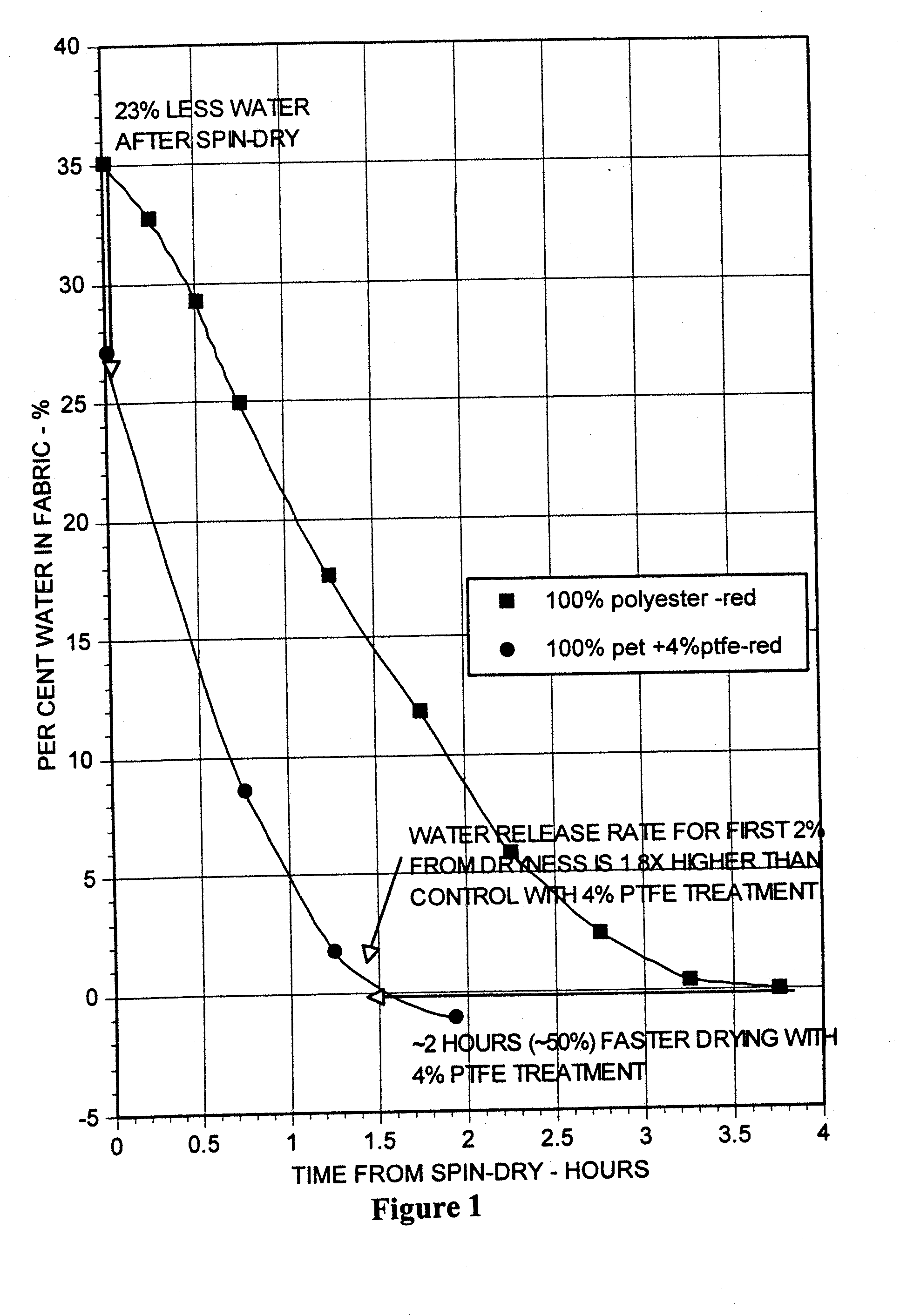

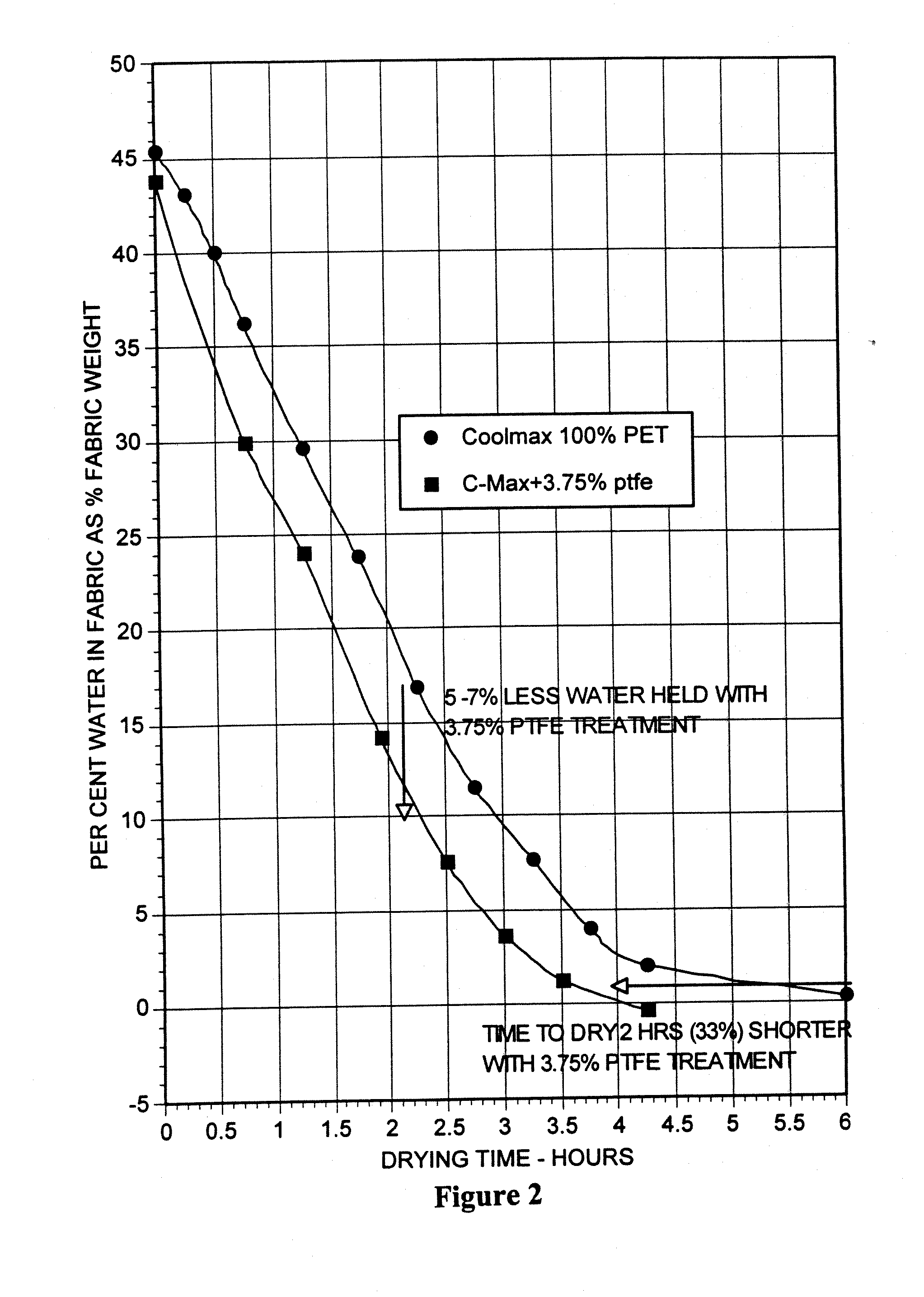

Treated T-Shirt Drying Times

[0092] In addition to the two samples from Example 1, t-shirts made from 100% CoolMax® polyester, an 88% co-polyester with 12% wool blend, an unbranded 100% polyester, an Akwatek®-treated hydrophilic Comfortrel® co-polyester, and a 100% cotton were treated similarly to the t-shirts in Example 1. The CoolMax® t-shirt picked up 3.74% PTFE, the 88% co-polyester with 12% wool blend t-shirt picked-up 3.28%, the unbranded 100% polyester t-shirt picked up 4% PTFE, the Akwatek®-treated hydrophilic Comfortrel® co-polyester t-shirt picked up 3.75% PTFE, and the 100% cotton t-shirt picked up 2.77% PTFE. All of the t-shirts were washed and spun dried in a Sears Kenmore 70 Series Heavy Duty Plus residential washing machine before and after treatment using 70 ml of Tide® detergent in a cotton / sturdy, warm / cold, medium load cycle. The t-shirts were weighed immediately after spin-dry to determine the water content of the t-shirts. The t-shirts were kept in a controlled ...

example 3

PTFE Transfer from Treated to Untreated T-Shirts

[0102] The 100% cotton t-shirts of Example 2 were washed with a red polyester shirt that had been treated previously with PTFE. FIG. 6 compares the drying rates of the treated and untreated t-shirts made from 100% cotton. Some of the red color transferred from the treated shirt to the untreated control. As shown in FIG. 6, the untreated t-shirt started with a water content that was 12% below the water content of the 2.8% PTFE treated t-shirt and both t-shirts dried at about the same rate. The comparable drying rates indicate that some of the PTFE treatment also transferred along with the dye from the treated shirt to the untreated control. The amount of PTFE treatment transferred was not measurable. Surprisingly, the low level of PTFE in the “untreated” control provided comparable results to the 2.8% PTFE treated samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight % | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com