Radio frequency controlled central vacuum endfitting

a technology of vacuum cleaner and vacuum handle, which is applied in the direction of suction handle, suction hose, suction cleaner, etc., can solve the problems of harkonen being in the means of stopping the vacuum cleaner and turning it off, and the wand being heavier, and achieves the effect of efficient and easy turning the central vacuum cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

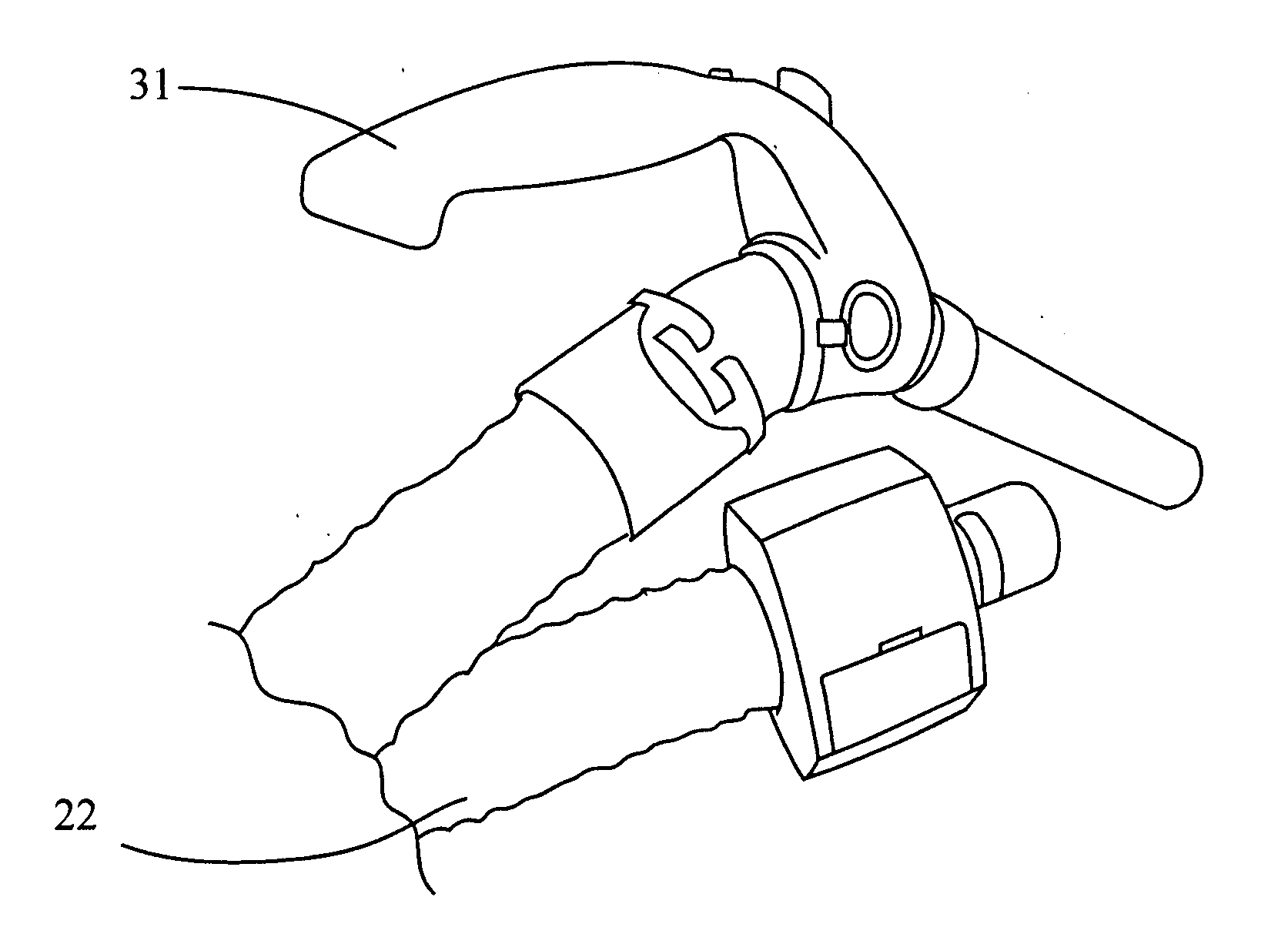

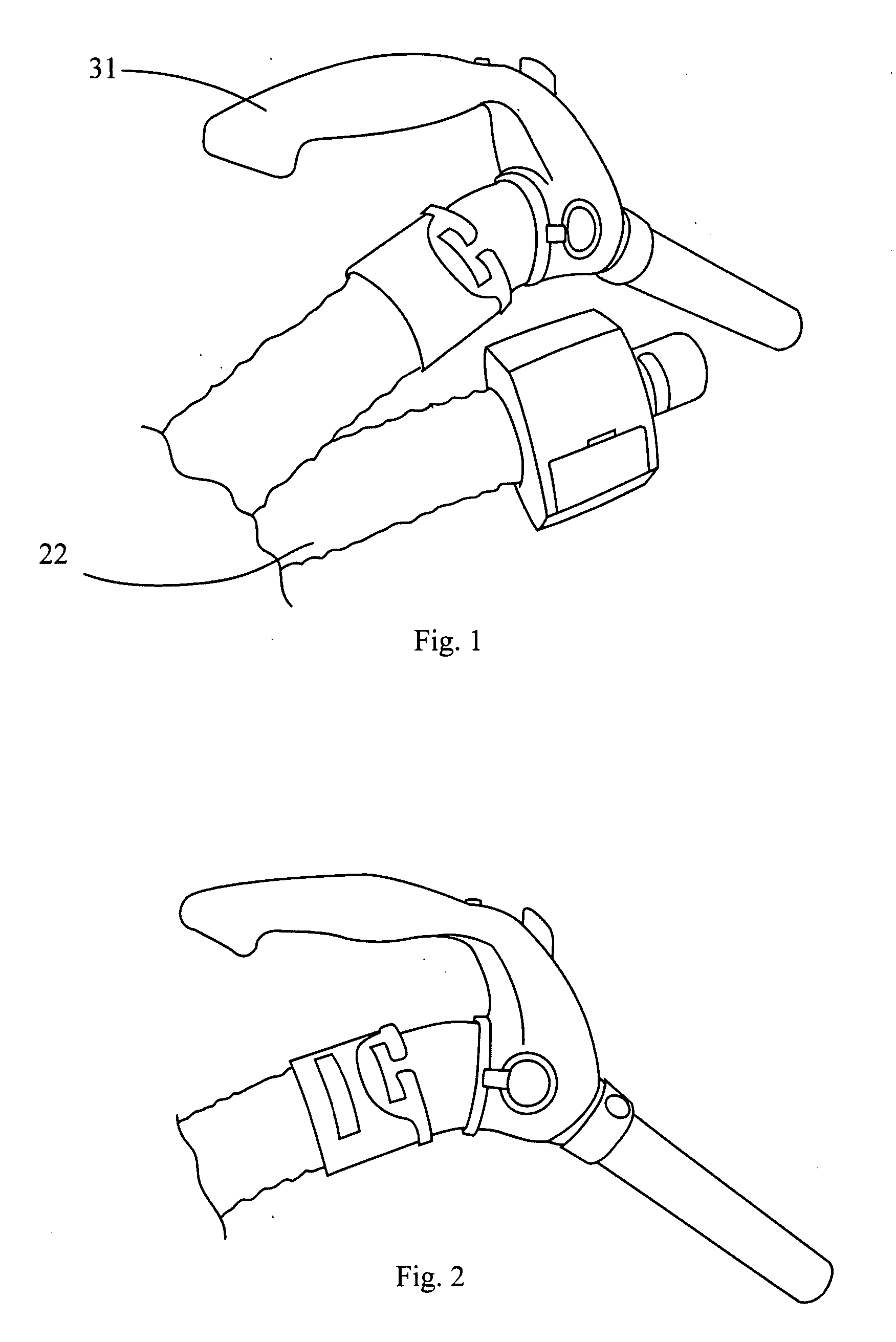

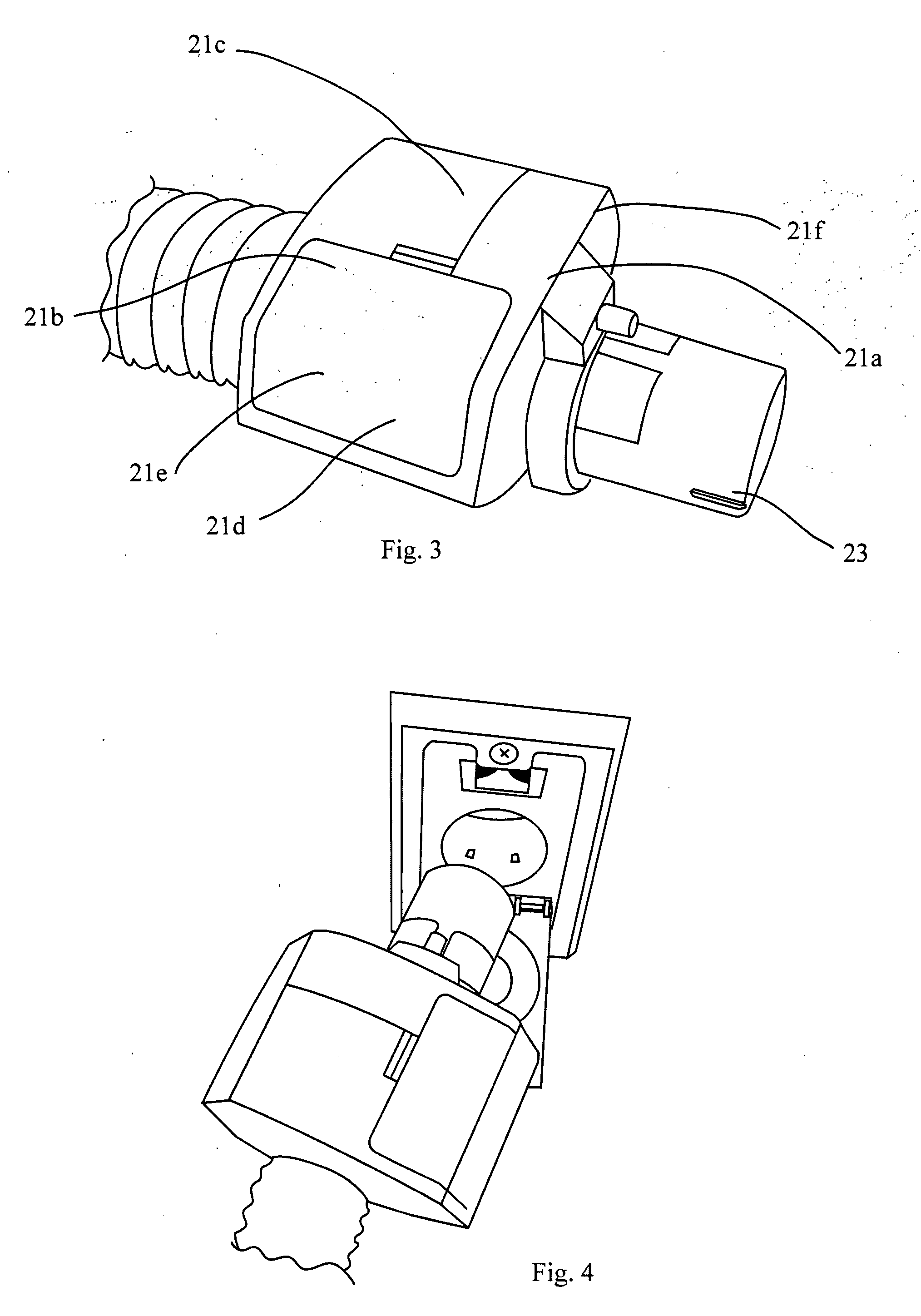

[0046] As seen in FIG. 1 there is one example of an embodiment of the central vacuum cleaner hose assembly 10, (hereinafter hose assembly) of the present invention. Although shown in connection with a receiver on an end fitting that is on one end of the hose, it will also be appreciated that the receiver can be elsewhere. For example, the receiver can be on the wall outlet or on the vacuum generating portion of the system of any other suitable location. The hose assembly of the present invention includes a first end fitting 20, a second end fitting 30, and a flexible hose 70. It will also be appreciated by those skilled in the art that the shape of the handle 20 and the end fitting 30 described in connection with one embodiment of the present invention can vary as desired. The hose may be any one of the hoses that are typically used in the art. As mentioned in the background of the invention, the switch in the handle may communicate with either the end fitting or the power head, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com