Silicon Nitride Layer for Light Emitting Device, Light Emitting Device Using the Same, and Method of Forming Silicon Nitride Layer for Light Emitting Device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

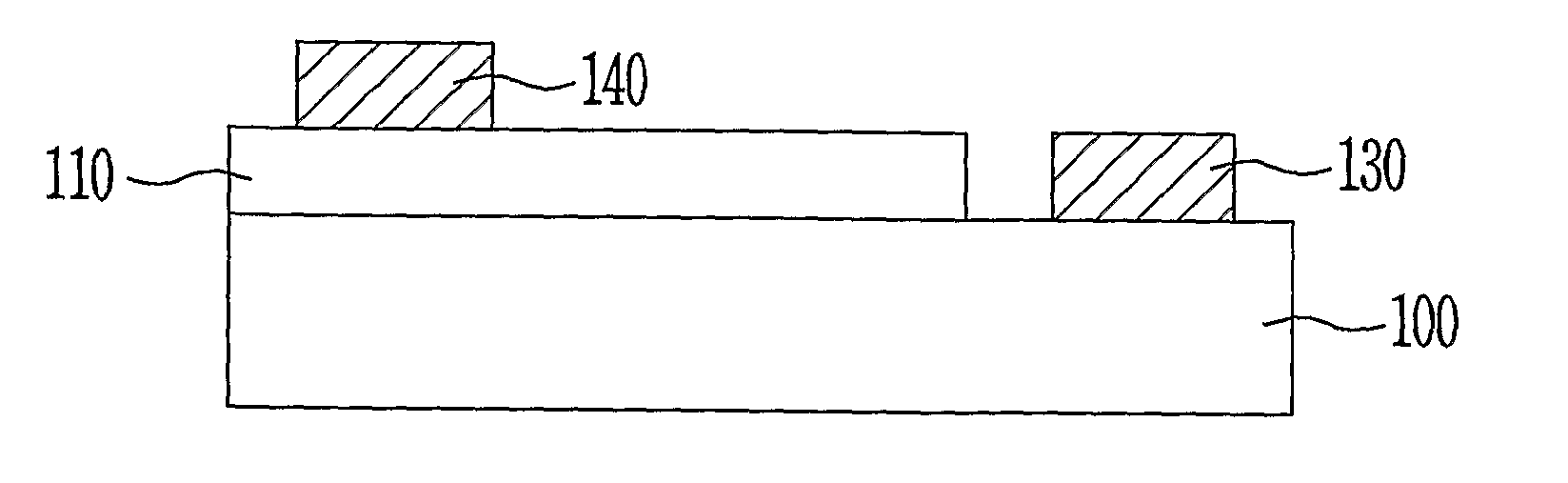

[0030]FIG. 1 is a cross-sectional view illustrating a process of forming a silicon nitride layer for a light emitting device according to an exemplary embodiment of the present invention.

[0031] Referring to FIG. 1, a silicon nitride matrix 20 is formed on a substrate 10, and silicon nanocrystals 30 are formed in the silicon nitride matrix 20.

[0032] The substrate 10 may be, but not limited thereto, a semiconductor substrate such as a silicon (Si) substrate and a germanium (Ge) substrate, a compound semiconductor substrate such as a SiGe substrate, a SiC substrate, a GaAs substrate, and an InGaAs substrate, or an insulating substrate such as a glass substrate, a sapphire substrate, a quartz substrate, and a resin substrate. However, when a silicon nitride layer is formed on a silicon substrate, the silicon substrate has better lattice match. Meanwhile, good lattice match can also be obtained when an additional silicon layer is formed on a substrate other than a silicon substrate and...

embodiment 2

[0050]FIG. 6 is a cross sectional view of a silicon light emitting device according to another exemplary embodiment of the present invention.

[0051] Referring to FIG. 6, a silicon emission layer 110 is formed on a predetermined region of a substrate 100, a p-type electrode 120 is formed on another predetermined region of the substrate 100 where the silicon emission layer 110 is not formed. Preferably, the substrate 100 is a p-type silicon substrate.

[0052] The silicon emission layer 110 may be formed using the above-described silicon nitride layer for the light emitting device according to the first embodiment and includes a silicon nitride matrix and silicon nanocrystals formed in the silicon nitride matrix.

[0053] Meanwhile, an n-type electrode 140 is formed on a predetermined region of the silicon emission layer 110. An n-type doping process may be performed using, for example, a P-based dopant, and a p-type doping process may be performed using, for example, a B-based dopant.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com